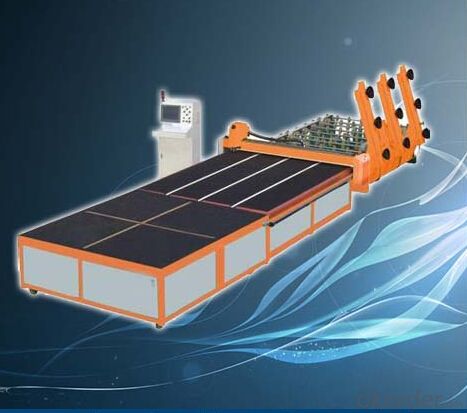

2015 Full and Semi automatic glass cutting machine for Bulk Glass Cutting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

We are a high-tech enterprise specialized in the research, manufacture and sale of Aluminum-PVC door & window production equipment,glass processing equipment. Our products sell very well in China and are exported to many foreign countries and regions.

We have many experienced technical engineers and experts who have been worked in this industry for many years.

2. Technical parameter:

1).Equipment performance

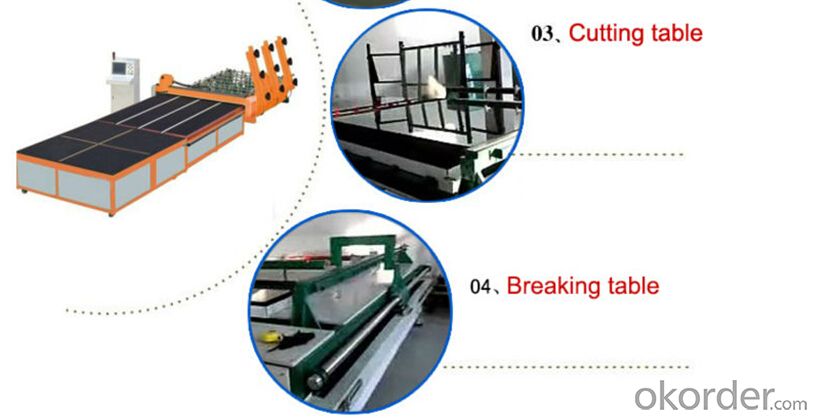

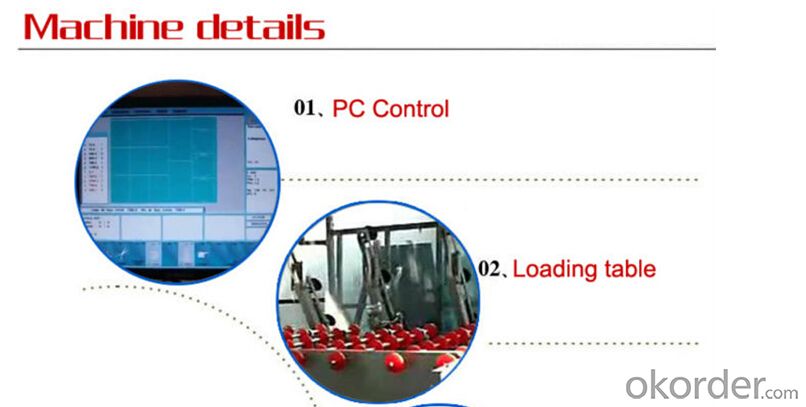

Cutting Holder: Using Japan SMC Proportion solenoid valves, According to the glass thickness automatic adjustment pressure, The cutting holder Rotate 360°.

2).Positioning System

Mechanical photoelectric joint positioning

3). Conveying Device

AIR and Belt conveyor

3. Features of our Machine Line

CNC Auto Glass Cutting Machine Production Line adopt the most advanced Italy software.

Use imported high precision rack, slider and servo-motor, can be operated longer and faster.

CNC process control system, photoelectric positioning, convenient and accurate, airbag cutting, smooth precision.

Applicable to construction curtain walls, auto windshield, crafts, furniture, hollow, solar glass, etc, or set cutting for linear or special-shaped glass.

4. Main Introduction: Automatic glass loading machine

If the product quality does not meet the standards set in your contract, Alibaba.com will refund the covered amount of your payment. On-time shipment protection

If your products are not shipped on time as per your contract, Alibaba.com will refund the covered amount of your payment. Payment protection

If the supplier breaks the on-time shipment or product quality terms of your contract, Alibaba.com will refund the covered amount of your payment. Product Details Company Profile Transactions History.

Report Suspicious Activity Company Information Packaging & Shipping Our Services FAQ Quick Details Condition: New Machine Type: Insulating Glass Production Line Production Capacity: 1200piece/day

Place of Origin: Shandong, China (Mainland)Brand Name: PARKER Model Number: IGV22

Voltage: 220-380v 50hzPower(W): 23.7kwDimension(L*W*H): 21000x2100x3300mm

Weight: 4800kgsCertification: CE Warranty: 1 years

5. Our Service for our customers

Packing and shipping

Packaging Detail: in plastic film and container

Delivery Detail: 30-60 days once receiving from the first payment

Payment terms

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: Can the engraving process 2*2mm grooves on plexiglass plates?

- In addition the organic glass softening temperature is not high, only more than 100 point temperature. Try hot pressing.

- Q: Can plexiglass be machined with CNC milling machines?

- It is usually done with laser engraving machines and mechanical engraving machines.In fact, the laser engraving machine works best.

- Q: Glass processing products; I do a glass processing plant, mainly to do insulating glass, I would like to ask what equipment you need to use, what price, please point out

- How much do you have to see the process, as well as post production; if small, with horizontal equipment, cheap; mainly glass washing machine, coating machine, Ding Ji two-component glue machine; if the production amount is very large, it is necessary to use vertical insulating glass production line and Ding Ji coating machine, double a glue machine.

- Q: Mobile phone glass engraving machine capable of processing large size?

- It depends on how large your equipment is. Many companies have carved machine alone making large stroke, according to the special processing of glass. Cell phone glass is no bigger than a tablet! Can be carved machine large stroke and biaxial processing of two pieces of flat glass. Let alone the cell phone

- Q: Status of glass machinery for glass machinery

- By the beginning of twentieth Century, there appeared the trend of following glass processing enterprises. Foshan, Shenzhen, Guangzhou, Shanghai, Hangzhou, Suzhou, Zhangjiagang and other relatively concentrated industrial areas have emerged. Its development area has expanded to the Shandong Peninsula to the Bohai rim area, and has spread to many cities in the mainland. At present, more than 50% of our country's glass cold processing equipments are manufactured in Guangdong and Shunde.By 2014, the development of glass machinery in China was highly dependent on the international market.

- Q: What milling cutters are used for machining plexiglass plates? Just ordinary drilling and milling machine, milling plane, not too precise

- Engraving machine is best to use, the speed is fast, and the accuracy is good

- Q: What are the main equipments for making insulating glass? How much would a whole set of funds be?

- If it is a composite glue bar, the insulating glass equipment only needs two sets of equipment, cleaning machine and heat sealing machine more than twenty thousand yuan.

- Q: Can glass fiber board be cut with laser cutting machine?

- Laser cutting machine is a kind of processing method which uses laser to produce high energy light beam, which can be melted or vaporized at an instant high temperature to be processed material. Compared with the traditional method of sheet metal processing, laser cutting has high cutting quality (incision width, small heat affected zone, smooth incision), cutting speed, cutting flexibility (or arbitrarily cut arbitrary shape), low processing cost, wide material etc.. Modern laser cutting technology has been widely used.

- Q: Can glass fiber reinforced plastics be machined with high precision?

- The mechanical processing of glass fiber reinforced plastics is quite possible.(1) the tool can be made of high speed steel or tungsten carbide of fine particle, because of hard alloy. If the amount is large, the requirements are relatively high, you can use artificial diamond (PCD) cutting tools.(2) the selection of machine tools depends mainly on the machining accuracy of your products. As you require 0.01 mm precision, the machine tool accuracy should be within 0.005 millimeters. Otherwise, how can we meet the requirements?

- Q: How much does it cost to open a glass grinding machine shop?

- Cleaning machine twenty-two thousand or so. I have this machine, so I can tell you the approximate price. Depending on what kind of glass you make, what machinery do you need?.

Send your message to us

2015 Full and Semi automatic glass cutting machine for Bulk Glass Cutting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches