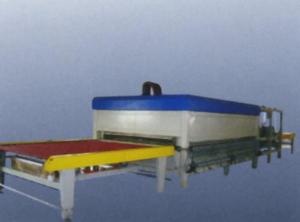

Tempering Furnace-3

- Loading Port:

- Dalian/Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Glass tempering furnace.Mainly termpering glass for domestic furniture,appliances,architectural decoration,shower booths,autombile,trains,ships,etc

- Q:What are door and window manufacturing equipment? Want to build a windows production processing equipment factory, about how much money?

- Aluminum Alloy doors and windows equipment sawing aluminum section glass bead saw corner cutting saw automatic (semi-automatic) heavy angle automatic cutting machine (CNC / digital) numerical control double head cutting saw heavy (efficient) single head cutting saw (NC) aluminum profile cutting machine of 45 aluminum doors and windows of arbitrary angle precision CNC double head cutting saw group. NC four head angle machine (vertical and horizontal) multi angle machine end milling head profile milling machine (Dan Tou) row curtain wall Tenoing machine milling machine milling machine (five knife) stamping press bending machine hardware punch hollow glass equipment vertical insulating glass production line of glass washing machine automatic production line automatic pressure plate rolling production line of vertical insulating glass production line glass washing machine horizontal hot press laminating horizontal cold roller press hollow glass auxiliary equipment of glass washing machine horizontal hot press and horizontal Sheet cold roll press curtain wall processing equipment, planer groove, drilling equipment, aluminum curtain wall composite board, planer slot machine

- Q:What equipment do you need to produce glasses? Is the process complicated? Are there many raw materials?

- The main raw materials for glass production are glass forming bodies, glass adjusting materials and glass intermediates, and the rest are auxiliary raw materials. The main raw materials, intermediate oxide and oxide to network oxides into the glass forming network; auxiliary materials including clarifying agent, fluxing agent, emulsifying agent, coloring agent, bleaching agent, oxidizing agent and reducing agent etc..

- Q:How is glass produced? How much does it cost to open a glass plant and what equipment do we need?

- Don't you save it also engage in mechanical mech workshop equipment is not so expensive to make money

- Q:How much is the equipment for toughened glass production?

- The base type machine is about 19 thousand; the drilling machine is about 18 thousand; the cleaning machine price is unknown; the specification requirement is 2500 type, but also depends on several levels of cleaning;

- Q:How much money do you need to invest in making glass hot bending? What equipment should I buy?

- It depends on what kind of hot bending glass you want to make, depending on the size of the glass

- Q:What brand machines do you need to produce double glass? How much is the equipment? How much is the material? Can a large area do? Do you use artificial water for producing ordinary drinking glasses?

- The production of double cup need automatic tube cutting machine, automatic necking machine, sealing machine, annealing oven, equipment investment of about 100 thousand, the material according to their production budget of 200 thousand, work area of 500 to 1000 level, you can find a master seal,

- Q:Glass processing products; I do a glass processing plant, mainly to do insulating glass, I would like to ask what equipment you need to use, what price, please point out

- Glass cleaning machine butyl rubber coating machine - two-component adhesive machine. The price is different, high and low.

- Q:Toughened glass machine more money?

- Look, what brand are you?.5 to 60 of all have

- Q:What are the processing methods of organic glass?

- Important points in hot bending of perspex:A. if you want to use water heating, do not "direct" heating by boiling, and use indirect heating so as not to change the size after moisture absorption.B. fixtures should be "level, smooth and clean" so as to avoid residual plastic lines and affect transparency.C. heating rate should not be too fast, should not exceed the thermal deformation temperature.D. cooling, the temperature of each part of the workpiece should be consistent. So the cooling rate is not too fast, otherwise heart with epidermal temperature difference caused by thermal stress, loosen fixture after deformation and back. Therefore, the cooling rate should not be too fast, the furnace will be better cold.The size of the E. after heat treatment will change slightly due to the two contraction, and the temperature should not be too high to reduce the shrinkage size.F. don't iron it, it will deform much more!G. specific heating time and temperature, it is necessary to experiment several times in order to master the best temperature, time.

- Q:Do you need professional tools for machining plexiglass? What about acrylic boards?

- 1, paste method: organic glass cut into a certain shape, paste in the flat surface.2 、 hot pressing method: after the plexiglass sheet is heated, the mold is hot pressed in the mold. The handicraft made by the molding method has the characteristics of full body, smooth curve and strong stereoscopic feeling, and has the effect of relief. The hot pressing mould can be made of wood and oil sludge, and then cast lead and plaster material as the Yin and Yang mold. After the organic glass is heated, it can be pressed and formed.3, mosaic method: the different colors of plexiglass block cut into the required geometry, in the bottom plate mosaic splicing. This method requires tight stitching, edges and corners, and a strong, yet seamless effect.4, vertical grinding method: rod shaped organic glass or thick plate plexiglass after bonding, grinding directly on the grinding wheel, polishing molding. The arts and crafts made by this method are similar to some sculptures. They are made up of colorful surface shapes to form a unique artistic image.

We are a manufacturer who has the ability of developing glass deep processing equipment and technology. It is one of the leading glass machinery designer and fabricator in China in manufacturing popular glass cold and hot processing machinery.

1. Manufacturer Overview |

|

|---|---|

| Location | Tianjin, China |

| Year Established | 2005 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | North America, South America, Eastern Europe, Africa, Oceania |

| Company Certifications | CE |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Tempering Furnace-3

- Loading Port:

- Dalian/Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords