2015 Full and Semi automatic glass cutting machine Laminated production Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

1.Our company is one of the best professional company, with 12 years history, specialized in manufacturing insulating glass machine, glass cutting machine, pvc & aluminum window and door machine.

2.Since our company founded, "best quality, mutual benefit" is always our principle, offering the best equipment and technical support for the old and new customers.

3.Our products has been exported to many countries, such as Asian countries, European countries, Middle East area ,and South American countries.

Normal machine is properly adjusted before dispatch. You will be able to use the machines immediately.

You will be able to get free training advice towards glass cutting machine in our factory. You will also get free suggestion and consultation,

technical support and service by email/fax/tel and lifetime technical support.

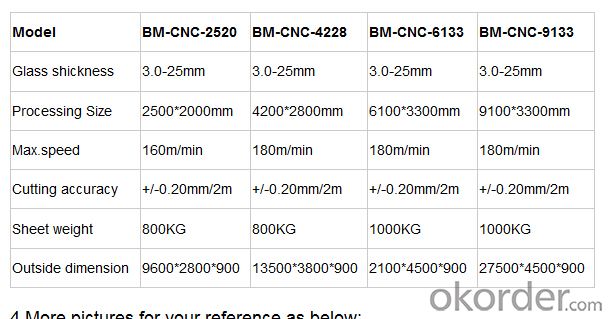

2. Technical parameter:

3. Features of our Machine Line

1). After starting the inputting machine, arms automatically suck glass from the shelf. Under sensor controlled, glass automatically find glass edge in the X and Y directions. After moving glass sheets to designated location, transport glass to the CNC cutting table. Under laser sensory element guidance, use laser-reader to get the position of the glass-sheet. Cutter will move to coordinate origin, and automatically start to cut according to the preinstall graph.

2). After cutting, glass will move to the Breaking Glass Table . Start break bars and to break the glass. At this point, the whole process work is completed.

4. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

Glass cutting line applies to: Building glass, insulated doors and windows, low-e glass, automobile glass, household appliance glass, furniture glass, solar energy glass, cook glass, mirrors, artwork glass and so forth.

5. Our Service for our customers

Payment Terms

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union

Warranty Terms

All equipments is 12 months guarantee,lifetime maintance.

After Sale Service

Generally speaking,our Insulating Glass Processing Equipments need to install by our professional technician, Aluminum&UPVC Windows and Doors Processing Equipments does not need.

If buyers need to install by our technicians, the installation clause as follows:

INSTALLATION CHARGE

USD70/day for one worker for installation and training. Buyer supply hotel,food,ticket. Our technical worker need about 3-10 days for installation till all machines is good. When our worker finished all installation, buyer have to pay for installation charger to our worker according to $70 per day. Then our worker will teach your worker how to operate all machines correctly.

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: What kinds of equipment are there in FRP production facilities?

- Paving equipment - use under special circumstances.Proportional coating equipment - if there are a number of components, heat it up in the heating molding equipment after gluing.

- Q: The thickness of the epoxy glass cloth laminates by machining method for machining the thin board?

- No; epoxy glass cloth laminates no ductility, ductility and so no pressure; plasticity is poor, can not be like wood scraping into thin sheet.

- Q: What kind of equipment and adhesives are needed for plexiglass processing?

- Cutting saw polishing machine polishing machine pistol drill trichloromethane disposable syringe Pervez silicone tape ruler compasses basically are the best in a curve saw

- Q: Status of glass machinery for glass machinery

- By the beginning of twentieth Century, there appeared the trend of following glass processing enterprises. Foshan, Shenzhen, Guangzhou, Shanghai, Hangzhou, Suzhou, Zhangjiagang and other relatively concentrated industrial areas have emerged. Its development area has expanded to the Shandong Peninsula to the Bohai rim area, and has spread to many cities in the mainland. At present, more than 50% of our country's glass cold processing equipments are manufactured in Guangdong and Shunde.By 2014, the development of glass machinery in China was highly dependent on the international market.

- Q: How to polish plexiglass and acrylic machine after machining?

- The flame polishing machine adopts electrochemical technology and uses the special reaction device to extract the oxyhydrogen gas from the water

- Q: Which equipment does the glass mirror need?

- Straight beveling machine = spell mirror is basically the bevel edgeWith the above equipment, you can make orders

- Q: Do you need professional tools for machining plexiglass? What about acrylic boards?

- 1, paste method: organic glass cut into a certain shape, paste in the flat surface.2 、 hot pressing method: after the plexiglass sheet is heated, the mold is hot pressed in the mold. The handicraft made by the molding method has the characteristics of full body, smooth curve and strong stereoscopic feeling, and has the effect of relief. The hot pressing mould can be made of wood and oil sludge, and then cast lead and plaster material as the Yin and Yang mold. After the organic glass is heated, it can be pressed and formed.3, mosaic method: the different colors of plexiglass block cut into the required geometry, in the bottom plate mosaic splicing. This method requires tight stitching, edges and corners, and a strong, yet seamless effect.4, vertical grinding method: rod shaped organic glass or thick plate plexiglass after bonding, grinding directly on the grinding wheel, polishing molding. The arts and crafts made by this method are similar to some sculptures. They are made up of colorful surface shapes to form a unique artistic image.

- Q: How do you make plexiglass?

- With a file or emery cloth for coarse grinding, chamfering and rounding with fine gauze and then polished, finally with ordinary toothpaste with a soft cloth polishing line. When grinding, pay attention to protect, good to hurt the front.

- Q: What are the mechanical equipments of float glass production line?

- Tin groove: tin bath is the key equipment for float glass production. The tin groove is made of refractory material. The outer shell is made of steel, and the whole tin groove is supported by the lower supporting steel structure. The support structure is unique, and the vibration of the fan and other mechanical vibration can be avoided to ensure the level of the tin surface.

- Q: How much does it cost to open a glass grinding machine shop?

- If the ordinary straight side, the machine is about forty-five thousand. Beveling machine ninety-five thousand or so. Shape machine about twenty-three thousand, drilling machine about twenty-three thousand.

Send your message to us

2015 Full and Semi automatic glass cutting machine Laminated production Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches