2 Tons Battery Powered Forklift CPD 20C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Forklifts are a critical element of warehouses and distribution centers. It’s imperative that these structures be designed to accommodate their efficient and safe movement. In the case of Drive-In/Drive-Thru Racking, a forklift needs to travel inside a storage bay that is multiple pallet positions deep to place or retrieve a pallet. Often, forklift drivers are guided into the bay through guide rails on the floor and the pallet is placed on cantilevered arms or rails. These maneuvers require well-trained operators. Since every pallet requires the truck to enter the storage structure, damage is more common than with other types of storage. In designing a drive-in system, dimensions of the fork truck, including overall width and mast width, must be carefully considered.

Dimensioning devices-fork truck mounted dimensioning systems provide dimensions for the cargo to facilitate truck trailer space utilization and to support warehouse automation systems. The systems normally communicate the dimensions via 802.11 radios. NTEP certified dimensioning devices are available to support commercial activities that bill based on volume.

Sideshifter - is a hydraulic attachment that allows the operator to move the tines (forks) and backrest laterally. This allows easier placement of a load without having to reposition the truck.

Rotator - To aid the handling of skids that may have become excessively tilted and other specialty material handling needs some forklifts are fitted with an attachment that allows the tines to be rotated. This type of attachment may also be used for dumping containers for quick unloading.

Fork positioner - is a hydraulic attachment that moves the tines (forks) together or apart. This removes the need for the operator to manually adjust the tines for different sized loads.

Roll and barrel clamp attachment - A mechanical or hydraulic attachment used to squeeze the item to be moved. It is used for handling barrels, kegs, or paper rolls. This type of attachment may also have a rotate function. The rotate function would help an operator to insert a vertically stored paper into the horizontal intake of a printing press for example.

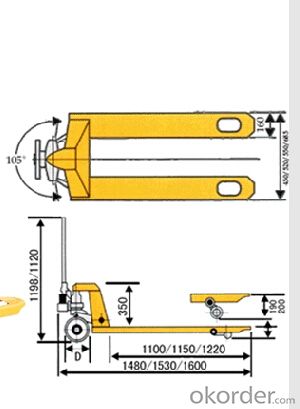

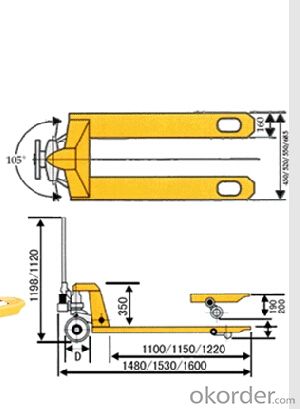

Forklift Specification:

Model | CPD20C | |

Load capacity kg | 2000kg | |

Load center mm | 500mm | |

Power type | Battery | |

Max.lifting speeds | 250mm/s | |

(with load)mm/s | ||

Max.Driving speeds | 12.5/14km/h | |

(with without load)km/h | ||

Max.Towing speeds | 10kN | |

(with load)kN | ||

Gradeability(with load)% | 15% | |

Lifting height mm | 3000mm | |

Free lift mm | 60mm | |

Tilting angles | 6/12(forward-backward) 。 | |

Min. turning radius mm | 2200mm | |

Min. right angle aisle width mm | 2050mm | |

Min. under-clearance mm | 110mm | |

Dimensions | A Overall length (inincluding fork) mm | 3350 |

B Overall width mm | 1160 | |

H Overall height(mast lowered) mm | 2130 | |

H2 Overall height(mast extend) mm | 4040 | |

H3 Overall height to overhead guard mm | 2130mm | |

B3 Fork width mm | 100mm | |

H4 Fork thickness mm | 40mm | |

A3 Fork length mm |

| |

A1 Fork overhang mm | 451mm | |

A2 Wheel base mm | 1550mm | |

Tread | Front tread mm | 970mm |

Rear tread mm | 950mm | |

Tyre | Front tyre | 7.00-12mm |

Rear tyre | 18×7-8mm | |

Total weight kg | 3950 | |

Motor | Traction motor | XQ-8 |

Lifting motor | XQD-10-3S | |

Battery | Battery type | D-600(700) |

Battery voltage/Capacity V/Ah | 48/600(700) | |

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: What are the procedures for buying a forklift?

- legal representative (or head) id card (such as entrust to handle, needs to submit a power of attorney at the same time the original and one copy each of the client id photocopy; id photocopy should I signature); The registration form of the special equipment (two copies of the original);

- Q: How many kilograms are on the top of the forklift truck

- For example, a three-ton forklift truck can withstand the impact of six tons of cargo.

- Q: How long is the forklift?

- Domestic forklift generally work for 1 year or 1000 hours, imported forklift generally work for 1 year, 2000 hours, the recent south Korean modern forklift truck out of a warranty 2 years or 3000 hours of work, already broke through the barrier forklift warranty!

- Q: What is the difference between a forklift and a trailer for a hydraulic drive?

- The hydraulic drive, forward and backward joystick is on the left hand, push forward (mechanical changeover valve) or move (the electromagnetism valve), the move forward; Back is the back. On the right hand side is a cargo fork operated valve, from the steering wheel to the right, in turn to lift, to tilt, to the tools (side shift, rotate, hold, etc.). The pedals move from left to right, braking, throttle. Hang up the ignition.

- Q: Is this the electric forklift truck?

- Electric forklifts are all stepless, and some have a fast speed.

- Q: Is a forklift a special type of work

- It is a special equipment operator. It is not necessarily a special type of work.

- Q: What rules do forklift drivers adhere to?

- First, people without special forklift training and authorization will not be allowed to operate any forklifts, and driving forklifts in the highway will require at least a B driver's license. To operate a forklift in the working area, you must have the driving license issued by the employer's book in person.

- Q: What do you need to do to get a forklift license from the quality technology supervision bureau? Is there a practical test for the forklift truck?

- Forklift license application conditions: according to the measures for the administration of special equipment operating personnel supervision (order no. 70 of the general administration of quality supervision, inspection and quarantine) article 10: apply for the personnel of special equipment operating personnel license shall meet the following conditions: Older than 18 years of age; Physical health and the specific requirements of the body for the type of work being applied; There is a degree of cultural adaptation to the type of application that is applied; Having a working experience with the type of job application,

- Q: About the safety of driving forklifts

- Keep in mind that the goods are overloaded and don't try, or you will be fired by your boss. Insert the insertion of the teeth, the distance between the teeth, the higher the load, the lower center of the drive.

- Q: What is a forklift for?

- Forklift plays a very important role in the logistics system of the enterprise, it is a very important component in logistics, it is the main force in the material handling equipment. Widely used in the national economy, such as station, port, airport, factory, warehouse, etc., it is an efficient equipment for mechanized loading and unloading, stacking and short distance transportation. Self-propelled forklifts appeared in 1917. During world war ii, forklifts were developed. China started making forklifts in the early 1950s. Especially with the rapid development of China's economy, the majority of enterprise material handling has been out of the original manual handling, instead of forklift truck is given priority to the mechanization of handling. As a result, demand in China's forklift market has grown at double-digit rates every year for the past few years.

Send your message to us

2 Tons Battery Powered Forklift CPD 20C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords