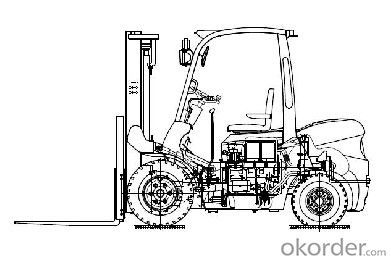

1.5 Tons Battery Powered Forklift CPD 15C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Electric forklifts - powered by lead-acid batteries, several types of forklifts are electric: cushion tire forklifts, scissor lifts, order pickers, stackers, reach trucks and pallet jacks. Electric forklifts are primarily used indoors on flat, even surfaces. Electric forklift batteries last 6 consecutive hours or throughout an 8-hour shift with 2-3 breaks. Batteries prevent the emission of harmful fumes and are recommended for facilities in food-processing and healthcare sectors.

Fuel cell forklifts produce no local emissions, can work for a full 8-hour shift on a single tank of hydrogen, can be refueled in 3 minutes and have a lifetime of 8–10 years. Fuel-cell-powered forklifts are often used in refrigerated warehouses as their performance is not degraded by lower temperatures.

Sideloader - comes in Stand on End Control, and Sit Down End Control, which is the most numerous. It may be electrically powered, or have an internal combustion engine. Engines may be diesel, kerosene, gasoline, natural gas, butane, or propane fueled, and may be either two stroke spark ignition, four stroke spark ignition (common), two stoke compression ignition, and four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries such as Iran or Russia will typically have no emission control systems. Some sideloaders have hybrid drivetrains.

Telescopic handler - comes in Stand on Center Control, and Sit Down Center Control, which is the most numerous. Usually has an Internal Combustion Engine. Engines are almost always diesel, but sometimes operate on kerosene, and sometimes use propane injection as a power boost. Some old units are two stoke compression ignition, most are four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries like Iran or Russia will typically have no emission control systems. Some Telescopic handlers have Hybrid drivetrains.

Walkie Order Picking truck - usually Electrically Powered

Rider Order Picking truck - commonly called an "Order Picker"; like a small Reach Truck, except the operator rides in a cage welded to the fork carriage, while wearing a specially designed safety harness to prevent falls. A special toothed grab holds the pallet to the forks. The operator hand transfers the load onto the pallet one article at a time. This is an efficient way of picking less than pallet load shipments, and is popular for use in large distribution centers.

A Raymond reach truck. Note the pantograph allowing the extension of the forks in tight aisles.

Articulated Very Narrow Aisle Counterbalanced trucks - sometimes called "Flexi or Bendi Trucks" after two of the largest manufacturers. Comes in Stand on Center Control, and Sit Down Center Control, which is the most numerous. May have an internal combustion engine or an electric motor. Electric motors are most common. Engines may be diesel, kerosene, gasoline, natural gas, butane, or propane fueled, and may be either two stroke spark ignition, four stroke spark ignition (common), two stoke compression ignition, and four stroke compression ignition (common). North American Engines come with advanced emission control systems. Forklifts built in countries such as Iran or Russia will typically have no emission control systems. Some units have hybrid drivetrains.

Forklift Specification:

Model | CPD15C | |

Load capacity kg | 1500kg | |

Load center mm | 500mm | |

Power type | Battery | |

Max.lifting speeds | 285mm/s | |

(with load)mm/s | ||

Max.Driving speeds | 12.5/14km/h | |

(with without load)km/h | ||

Max.Towing speeds | 6.5kN | |

(with load)kN | ||

Gradeability(with load)% | 15% | |

Lifting height mm | 3000mm | |

Free lift mm | 60mm | |

Tilting angles | 6/12(forward-backward) 。 | |

Min. turning radius mm | 1820mm | |

Min. right angle aisle width mm | 1810mm | |

Min. under-clearance mm | 95mm | |

Dimensions | A Overall length (inincluding fork) mm | 2960 |

B Overall width mm | 1086 | |

H Overall height(mast lowered) mm | 2115 | |

H2 Overall height(mast extend) mm | 4015 | |

H3 Overall height to overhead guard mm | 2115mm | |

B3 Fork width mm | 100mm | |

H4 Fork thickness mm | 35mm | |

A3 Fork length mm | 920(1070)mm | |

A1 Fork overhang mm | 436mm | |

A2 Wheel base mm | 1250mm | |

Tread | Front tread mm | 900mm |

Rear tread mm | 920mm | |

Tyre | Front tyre | 6.50-10mm |

Rear tyre | 5.00-8mm | |

Total weight kg | 3050 | |

Motor | Traction motor | XQ-5-4A3 |

Lifting motor | XQD-7.5-3C | |

Battery | Battery type | D-440 |

Battery voltage/Capacity V/Ah | 48/440 | |

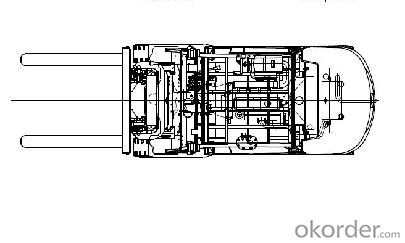

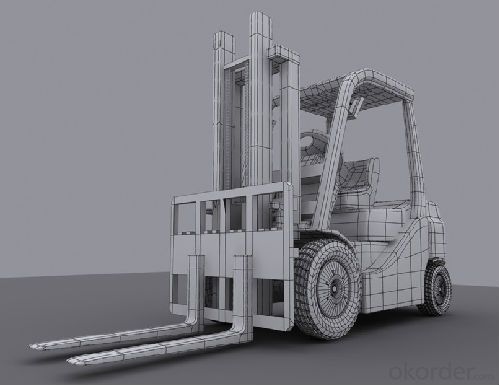

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: How to start a forklift? Say detailed point

- Check for safety around forklifts: make sure there is no one around your forklift before starting a forklift truck. When a large cargo is carried, when the eye is not good, please turn the car or be guided by others. When driving backwards, make sure there is no one around the forklift. When driving a forklift in a narrow passageway, you should be guided. Drivers should stop at the crossroads or other areas of sight to make sure that they drive when they are empty. Unlike a car, a forklift is a rear wheel that moves toward a turning point, lowering the speed and then turning the steering wheel to turn the back of the forklift. Be aware of pedestrians, obstacles and potholes, and notice the clearance above the forklift truck. Upper and lower forklift: stop jumping and jumping off the forklift truck. As you go up and down the car, grab the handle and step on the pedal. You can't grab a steering wheel or a joystick when you're driving up and down. Forklifts are forbidden: forks and pallets are strictly prohibited. Do not allow anyone other than the driver to ride. Don't replace the balance by employing people. Start the power with the key and see if the dashboard is normal: Check if the vehicle is empty;

- Q: Where can I get a forklift

- If you want to learn forklift, I can recommend a good forklift school, in dongcheng, dongguan experimental mechanic school, which is assigned. Very good!

- Q: What's the tonnage of the forklift

- Side forklift Powered by diesel engine, the carrying capacity is 3.0-6.0 tons. In the case of not turning, the ability to take the goods directly from the side and fork, therefore, the main purpose is to take the long line of goods such as wood bar, steel bar and so on.

- Q: A forklift applies to which industries

- There are more kinds of forklifts and special forklifts. Basically, with the more places are logistics warehousing, factories and individual production for self-use (now most factories are used as food, paper, machining industry, equipment manufacturing, parts manufacturers), port (container). The forklift is a kind of can replace the artificial production tools, with low cost high efficiency has a wide application range, and in the process of economic development in the future will be to use more and more. If you need a forklift to contact me, I am a manufacturer.

- Q: Is this the electric forklift truck?

- Logistics company if outdoor use can use more diesel forklift, may at any time come on, don't worry about the rain, the manual is ok, the operation is simple, automatic transmission dynamics. Battery forklifts need to be charged. But the electric bottle forklift truck is environmentally clean and less maintenance. In addition, the truck is loaded with a load of 1.5-3.0 T, requiring only diesel forklifts. The pure hand dozen, please accept.

- Q: Notice those items before the forklift

- Check the vehicle Before (1) forklifts, the appearance should be inspected, and the fuel, lubricating oil and cooling water should be added. (2) check start-up, operation and braking performance. (3) check the lighting and sound signal to be fully effective.

- Q: How about the forklift truck training, the forklift wages

- As the saying goes, the skill is no burden, for some have no record of formal schooling, and without any special skills, learn a skill alongside the body should be the right thing to do, learning forklift is right choice, forklift worker's monthly salary composition material member forklift driver: post salary + skills allowance + fall class expense + on performance-related pay receiving, issuing forklift driver: salary + month performance salary + skills allowance job salary is the basic wage, this related to many factors, such as local economic level, the wage, the skill level of the individual, etc., usually ranging from 2000-3000 implementation skills allowance for forklift driver positions. The reward salary for the skill level that the individual has received in the position, encourages the employee to do the job well

- Q: What is the cause of my forklift

- I also drive a forklift truck for TCM. The forklift doesn't start. You check the battery first. Turn on the light and see if the lights are on. If the light is not on, you again with two wires connect a small bulbs, connected to the battery to 12 v, see if the battery's dead, if the light is, is the problem line. Check each item, the speaker doesn't ring. And so on. Looks like you're a beginner.

- Q: The forklift truck can't be combined for a license

- No, the loading machine belongs to the engineering machine, the forklift truck belongs to the logistics machinery, different industries. And the loading machine is in the security check, can run an operation card, the forklift truck is returned to the quality inspection tube.

- Q: I want to learn about the forklift truck. I don't know how well the forklift man works.

- Find a job that is easy to find, and go to the feed factory. At least 3,500 in January, there are five to six thousand, and I did it at the feed factory. You can also go to the electronics factory, but the salary may be more than 3, 000, but it's fun and easy. The answer can help a friend's words, thanks

Send your message to us

1.5 Tons Battery Powered Forklift CPD 15C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords