3.5 Tons Battery Powered Forklift CPD 35C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

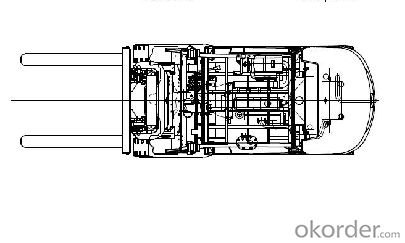

Image of an electric forklift with component descriptions

Truck frame - is the base of the machine to which the mast, axles, wheels, counterweight, overhead guard and power source are attached. The frame may have fuel and hydraulic fluid tanks constructed as part of the frame assembly.

Counterweight - is a mass attached to the rear of the forklift truck frame. The purpose of the counterweight is to counterbalance the load being lifted. In an electric forklift the large lead-acid battery itself may serve as part of the counterweight.

Cab - is the area that contains a seat for the operator along with the control pedals, steering wheel, levers, switches and a dashboard containing operator readouts. The cab area may be open air or enclosed but it is covered by the cage-like overhead guard assembly. When enclosed, the cab may also be equipped with a cab heater for cold climate countries along with a fan or air conditioning for hot weather.

Overhead guard - is a metal roof supported by posts at each corner of the cab that helps protect the operator from any falling objects. On some forklifts, the overhead guard is an integrated part of the frame assembly.

Power source - may consist of an internal combustion engine that can be powered by LP gas, CNG, gasoline or diesel fuel. Electric forklifts are powered by either a battery or fuel cells that provides power to the electric motors. The electric motors used on a forklift may be either DC or AC types.

Tilt cylinders - are hydraulic cylinders that are mounted to the truck frame and the mast. The tilt cylinders pivot the mast backward or forward to assist in engaging a load.

Mast - is the vertical assembly that does the work of raising and lowering the load. It is made up of interlocking rails that also provide lateral stability. The interlocking rails may either have rollers or bushings as guides. The mast is driven hydraulically, and operated by one or more hydraulic cylinders directly or using chains from the cylinder/s. It may be mounted to the front axle or the frame of the forklift. A 'container mast' variation allows the forks to raise a few meters without increasing the total height of the forklift. This is useful when double-loading pallets into a container or under a mezzanine floor.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

An important aspect of forklift operation is that most have rear-wheel steering. While this increases maneuverability in tight cornering situations, it differs from a driver’s traditional experience with other wheeled vehicles. While steering, as there is no caster action, it is unnecessary to apply steering force to maintain a constant rate of turn.

Another critical characteristic of the forklift is its instability. The forklift and load must be considered a unit with a continually varying center of gravity with every movement of the load. A forklift must never negotiate a turn at speed with a raised load, where centrifugal and gravitational forces may combine to cause a disastrous tip-over accident. The forklift are designed with a load limit for the forks which is decreased with fork elevation and undercutting of the load (i.e., when a load does not butt against the fork "L"). A loading plate for loading reference is usually located on the forklift. A forklift should not be used as a personnel lift without the fitting of specific safety equipment, such as a "cherry picker" or "cage".

Forklifts are a critical element of warehouses and distribution centers. It’s imperative that these structures be designed to accommodate their efficient and safe movement. In the case of Drive-In/Drive-Thru Racking, a forklift needs to travel inside a storage bay that is multiple pallet positions deep to place or retrieve a pallet. Often, forklift drivers are guided into the bay through guide rails on the floor and the pallet is placed on cantilevered arms or rails. These maneuvers require well-trained operators. Since every pallet requires the truck to enter the storage structure, damage is more common than with other types of storage. In designing a drive-in system, dimensions of the fork truck, including overall width and mast width, must be carefully considered.

Forklift Specification:

Load center mm | 500mm | |

Power type | Battery | |

Max.lifting speeds | 285mm/s | |

(with load)mm/s | ||

Max.Driving speeds | 13.5/15km/h | |

(with without load)km/h | ||

Max.Towing speeds | 12kN | |

(with load)kN | ||

Gradeability(with load)% | 15% | |

Lifting height mm | 3000mm | |

Free lift mm | 75mm | |

Tilting angles |

| |

Min. turning radius mm | 2400mm | |

Min. right angle aisle width mm | 3900mm | |

Min. under-clearance mm | 140mm | |

Dimensions | A Overall length (inincluding fork) mm | 3745 |

B Overall width mm | 1240 | |

H Overall height(mast lowered) mm | 2200 | |

H2 Overall height(mast extend) mm | 4260 | |

H3 Overall height to overhead guard mm | 2200mm | |

B3 Fork width mm | 125mm | |

H4 Fork thickness mm | 50mm | |

A3 Fork length mm |

| |

A1 Fork overhang mm | 495mm | |

A2 Wheel base mm | 1700mm | |

Tread | Front tread mm | 1000mm |

Rear tread mm | 980mm | |

Tyre | Front tyre | 28×9-15mm |

Rear tyre | 18×7-8mm | |

Total weight kg | 5160 | |

Motor | Traction motor | XQ-10-1C |

Lifting motor | XQD-13-3S | |

Battery | Battery type | 40-DA-500 |

Battery voltage/Capacity V/Ah | 80/500 | |

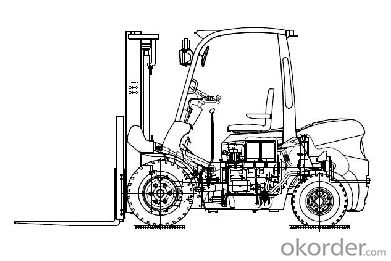

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: How wide is the internal-combustion forklift pass?

- I wonder what the price you can accept? The diesel must be larger than the electric forklift and the net width of linde's E16C channel can be left to 3.3 meters, with a payload of 1.6 tons. What is the size of the card board? The length of the fork is not less than 2/3 of the way the card is in the direction of the fork. 1070 is the standard configuration of Japanese and domestic brands, you can lengthen your custom, you can't spend much. The forklift advice is not overloaded, the first is safety and the second is the damage to the product's hydraulic system.

- Q: How does the forklift start?

- Some have ignition locks, others open the keys, have a start button and hold it up.

- Q: Why are there two kinds of special equipment operators

- Hello, the certificate department is different. The special equipment operator's certificate is issued by the bureau of quality and technical supervision. The operation certificate of special operator is issued by the security bureau. The quality technology supervision bureau's certificate is: Special equipment operator certificate Type: special motor vehicle operation in field (factory) Work item: forklift driver Item code: N2

- Q: Where is the enterprise forklift special operation certificate?

- The operation certificate of special operation of the forklift truck is handled in the administrative service center. A special operations training organization shall apply for a certification procedure The training courses for special operations must be reported to the city security bureau in advance. The special operations training organization shall, in the week before the application for examination, be submitted to the municipal security bureau for reference. 3, city bureau to apply for the inspection report, and training institutions agreed to the inspection date and send inspection member to the examiners training institutions, examination paper copies, according to the register population to determine test after sealed by the inspection member carry. After the evaluation is over, the appraisals will be evaluated within 2 days.

- Q: Does the forklift have only one wheel? Front engine

- The two wheels are two sticks stuck can't turn a circle, and mat under the hard objects slippage of the wheels, the as long as let slip side is enough resistance can

- Q: Does anyone know what is the principle of explosion protection forklift truck?

- Watson explosion-proof forklift truck quality is not bad, it is also one of the domestic rare good explosion forklift truck manufacturer Passed the national explosion-proof test, explosion-proof principle of specific can consult on Watson website, there will be a professional solution for you. The hope can help you..

- Q: The component of electric forklift drive system

- An electric forklift is a forklift, which USES electricity to do its work, mostly for batteries. The battery is a type of battery that is used to store a limited amount of electricity in the right place. It works by converting chemical energy into electricity. This is the battery in the battery of an electric forklift. Be careful: the battery had better not be horizontal! Because the interior of the battery is typically 22 to 28 percent of dilute sulphuric acid. Battery is put electrolyte can drown plate and left a little space if the battery laid-down there will be a part of the plate electrode exposed to air, this is very bad for battery plate, and the general observation hole or the top of the battery cells are vent communicates with the outside world, so the battery electrolyte askew is easy to flow out.

- Q: What is a forklift truck

- In general paper goods factory USES a lot of, be in the forklift truck to add a clip to call a hug car

- Q: Where should I take the special operation equipment certificate for the forklift?

- I got a preliminary certificate for forklift in a free training session for the community summer vacation. There is no working experience. Big companies hire forklifts for special operations.

- Q: I want to learn about the forklift truck. I don't know how well the forklift man works.

- Find a job that is easy to find, and go to the feed factory. At least 3,500 in January, there are five to six thousand, and I did it at the feed factory. You can also go to the electronics factory, but the salary may be more than 3, 000, but it's fun and easy. The answer can help a friend's words, thanks

Send your message to us

3.5 Tons Battery Powered Forklift CPD 35C

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords