2-75mm Thick Float Glass, Tempered Glass, Insulated Glass,Laminated Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass:

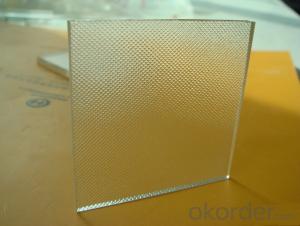

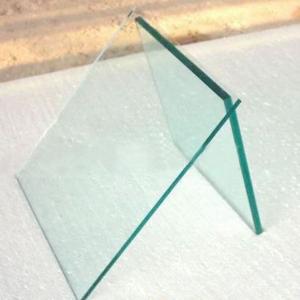

We produce all kinds of glass to meet your different needs: float glass, colored glass, stained glass, laminated glass, glass mirror, aluminum mirror, silver mirror, reflective glass, on-line coated glass, embossed glass, embossed glass, wired glass, stained glass, tempered glass, toughened glass, safety glass, glass shower door, emulsification glass, acid etched glass, embossed glass, frosted glass, solar glass, ultra white low iron glass, Low-E glass, embossed glass, glass brick, glass bricks, in different colors and sizes of photo.

2.Main features of Glass:

1) standard: Intertek, CCC

3) 2 ~ 19mm float glass

3) size: customizable size

4) tempering or silk

5) drilling

6) print furniture glass, beautiful surface has a good cover.

Special glass, as your design and requirements

Type: transparent, coloured, color glaze, coating, LOW-E insulating glass, laminated glass, etc.,

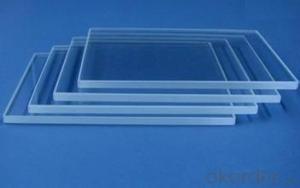

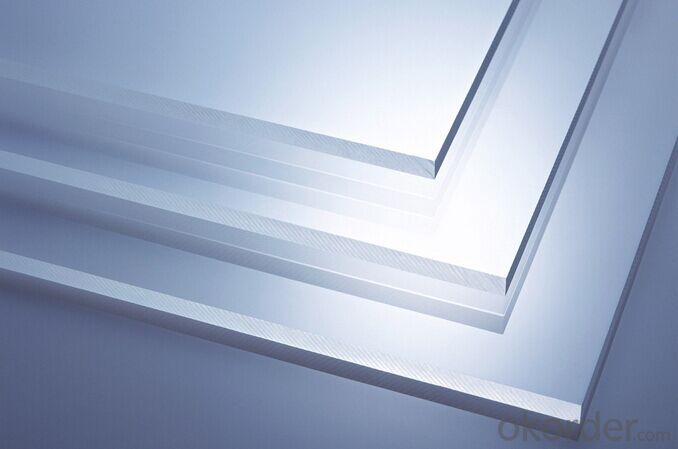

3.Glass Images:

4. Glass Technical Parameters:

CLEAR FLOAT GLASS

Thickness: 2mm-19mm

Sizes: 1524x2134mm, 1830x2440mm, 2140x3300mm, 2140x3660mm, 2250x3300mm, 3660x2140mm, 3660x2250mm etc.

EXTRA CLEAR GLASS

Thickness: 3mm-19mm

Sizes: 1830x2440mm, 2140x3300mm, 2140x3660, 2250x3300mm, 2250x3660mm etc.

TINTED GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Mist Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Ocean Blue, Pink etc.

Thickness: 3mm-12mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm, 2140x3660mm, 2250x3160mm etc.

REFLECTIVE GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Pink, Silver etc.

Thickness: 3mm-10mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm etc.

MIRROR

Types: Silver Mirror, Aluminum Mirror, Copper and Lead Free Mirror, Safety Mirror, Solar Mirror and Beveled Mirror etc.

Thickness: 1.5mm, 1.8mm, 2mm, 2.7mm, 3mm, 4mm, 5mm and 6mm etc.

Sizes: 1524x2134mm, 1830x1220mm, 1830x2440mm, 2140x3300mm, 2250x3300 etc.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system, from raw materials to the final product, we have strict quality inspection, we resolutely put an end to substandard products into the market. At the same time, we will provide the necessary follow-up service guarantee.

- Q: How do you make the glass, please? What is the raw material?

- If there is, use calcium carbonate, silica, and sodium carbonate in a platinum crucible or clay crucible or corundum (alumina) crucible and melt to obtain glass.

- Q: Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Acrylic board and plexiglass"Organic glass" from English Organic Glass. in recent years in some areas will be made of transparent plastic sheet all are called organic glass, actually this is wrong, it refers to pure acrylic polymethylmethacrylate (PMMA) and the PMMA sheet material, called the acrylic plate.

- Q: What is the raw material of glass made of?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history. The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass.

- Q: What are the raw materials of glass fiber reinforced plastic?

- If they are bonded together with synthetic resins, they can be made of rigid products of a fixed shape, bearing both tensile and flexural, compressive, and shear stresses.

- Q: What are the raw materials made of glass and plastics?

- Polyethylene (Polyethylene, PE), referred to as PE. is ethylene organic polymer compound. Polyethylene is the best material in contact with food. Non-toxic, tasteless and odorless, conform to the hygiene standards of food packaging. Polyethylene film, transparent, with moisture, oxygen, anti acid and alkali resistance, air tightness in general, excellent heat sealing properties. Known as "plastic flowers" reputation. Plastic packaging and printing volume is the largest and most important materials.PVC-- PVC

- Q: A fireproof material is? Except glass wool, rock wool? Please tell me what is the raw material of these materials is?

- Phenolic insulation board is based on phenolic resin and flame retardant, anti smoke agent, a variety of material, curing agent, foaming agent and other additives, closed cell rigid foam made by scientific formula. The most prominent advantage is fireproof and insulation.

- Q: What is the raw material of glass fiber reinforced plastics and what is the matching ratio?

- The main raw material is unsaturated resin and fiber cloth,

- Q: Samsung LCD panel information

- Landlord, you take this screen is not the LCD screen, and the other is the plasma screen.It should be a 46 inch plasma TV set.

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- Float glass: float glass surface flat, good brightness, no bubble and tumorLattice glass: the surface of the lattice is not very smooth, and the ripples can be seen from the side. Uneven thickness

- Q: What is the density of glass flake cement?

- The bulk density of glass flake increases with the decrease of particle size.Glass flake resin (Glass flake mastic) is made of resin as binder, glass flake and powder, etc. it can be scraped and mixed with construction materials.

Send your message to us

2-75mm Thick Float Glass, Tempered Glass, Insulated Glass,Laminated Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords