HDPE Geocell for Road Reinforcement with Different Welding Distance

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

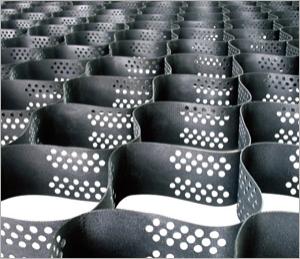

Geocell Description

Geocell is high-molecular polymer, connected by rivets or ultrasonic welded to three-dimensional network structure, unfold it and fill in sand, gravel and clay, etc. when used at construction site.

According to customer’s requirement, cut holes or carve arabesquitic in order to increase its lateral permeable ability, also increase the friction and binding force with the foundation material.

Geocell Specification

Welding distance:330-1000mm

Height:50-250mm

Surface: Textured or Smooth

Color: black,brown,green

Geocell Property:

1) Retractile, foldable when transportation, pulled to net work when construction, fill in the soil, gravel, concrete, atc. Loose materials,

form one structure with strong lateral limitations and high stiffness.

2) Material is light, abrasion resistance, chemical properties stable, resist photooxidation aging, acid and alkali resistant, suitable for different soil and soil conditions, such as desert.

3) Good lateral restrict and prevent slippery, prevent deformation, effectively enhance the bearing capacity of subgrade and dispersed

loads function.

4) The geocell height and welding distance etc. geometric dimensions are all changeable in order to meet the requirement of different projects.

5) Capable and easily be expanded or contracted, small size for transportation, easy for connect and construction speed is fast.

Geocell Application

1) Used for the stability of railway road.

2) To stabilize the desert highway road.

3) Used in the governance of shallow water channel.

4) Used for the foundation reinforcement of retaining wall, wharf, levee.

5) For the management of desert, beaches and river banks

- Q:How do geocells help with load distribution on soft soil?

- Geocells, which are three-dimensional honeycomb-like structures made of high-density polyethylene, help with load distribution on soft soil by confining and stabilizing the soil particles within their cells. This confinement increases the soil's shear strength, thereby reducing its deformation and settlement under load. The interconnected cells also create a network that distributes the load over a wider area, reducing the pressure exerted on the soil and preventing localized failures. Overall, geocells provide reinforcement and improve the load-bearing capacity of soft soil, making it suitable for various construction and infrastructure projects.

- Q:Are geocells resistant to temperature variations?

- Yes, geocells are designed to be resistant to temperature variations. They are typically made from high-density polyethylene (HDPE) which has excellent temperature resistance properties. This allows geocells to withstand both hot and cold temperatures without significant deterioration or deformation.

- Q:Can geocells be used in earthquake-prone areas?

- Yes, geocells can be used in earthquake-prone areas. Geocells are a type of cellular confinement system that can provide reinforcement and stability to soil and slopes. They can help mitigate the effects of seismic activity by confining and reinforcing the soil, improving its shear strength and resistance to liquefaction. Additionally, geocells can be used for retaining walls, embankments, and erosion control in earthquake-prone areas, making them a suitable solution for enhancing the stability and resilience of the ground in such regions.

- Q:Can geocells be used in shoreline protection?

- Yes, geocells can be used in shoreline protection. Geocells are three-dimensional cellular confinement systems made of high-density polyethylene (HDPE) that can be filled with soil, aggregate, or concrete. They provide structural support and stabilization to shorelines by preventing erosion, reducing wave energy, and promoting vegetation growth. Additionally, geocells are cost-effective, easy to install, and environmentally friendly, making them a suitable choice for shoreline protection projects.

- Q:How do geocells improve water drainage?

- Geocells improve water drainage by providing a stable, permeable structure that helps distribute and channel water away from the surface. The interconnected cells allow for efficient water flow through the system, preventing water accumulation and reducing the risk of erosion.

- Q:Are geocells suitable for railway track embankment reinforcement?

- Yes, geocells are suitable for railway track embankment reinforcement. Geocells provide a stable and strong foundation that helps distribute load and reduce settlement, preventing track distortions and improving overall stability. Additionally, geocells improve the bearing capacity of the embankment, increasing its resistance to lateral forces and erosion.

- Q:Are geocells suitable for constructing athletic tracks?

- Yes, geocells are suitable for constructing athletic tracks. Geocells provide a stable and durable base for the track, ensuring proper drainage and preventing the formation of potholes or cracks. Additionally, they offer excellent load distribution, reducing the chances of track deformation and providing a smooth surface for athletes. Geocells also help to control lateral movement, enhancing the overall stability and longevity of the athletic track.

- Q:What is the typical length of a geocell panel?

- The typical length of a geocell panel can vary depending on the manufacturer and specific application, but it is commonly around 1 meter (3.3 feet) to 2 meters (6.6 feet).

- Q:Can geocells be used in wetland restoration projects?

- Yes, geocells can be used in wetland restoration projects. Geocells are a versatile and effective solution for stabilizing soil in various applications, including wetlands. They provide structural support, prevent erosion, and promote vegetation growth, making them suitable for wetland restoration efforts.

- Q:Can geocells be used in pond and lake lining projects?

- Yes, geocells can be used in pond and lake lining projects. Geocells are a type of cellular confinement system that can provide stability and reinforcement to the soil or aggregate used in lining ponds and lakes. By using geocells, the lining material is confined within the cells, preventing erosion and maintaining the integrity of the lining system. Additionally, geocells can enhance the load-bearing capacity of the lining material, making it suitable for various applications, including pond and lake lining projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Geocell for Road Reinforcement with Different Welding Distance

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords