CE Certified HDPE Geocells for Erosion Control in Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of HDPE Geocell used in Road Construction

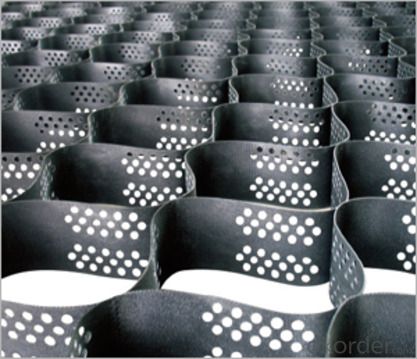

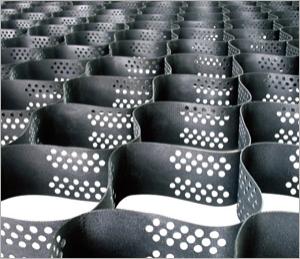

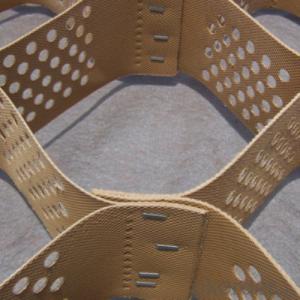

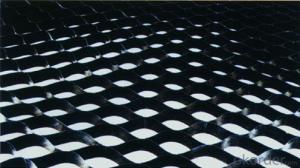

Geocell is made of high-strength HDPE or PP broadband, which are welded into a piece of netty cell structure, it can be stretched out and folded easily. It can be folded in course of conveyance while being stretched out; soil, stone or concrete can be filled into it, which will become a structure body with big side restriction and high strength. It can be used as a cushion to deal with weak foundation increasing the load capacity, and can also be laid on the slope to be made up the protecting structure.

Main Features of HDPE Geocell used in Road Construction

1. Retractile,foldable when transportation,pulled to network when construction,fill in the soil,gravel,concrete etc. loose materials,form one structure with strong lateral limitations and high stiffness;

2. Material is light,abrasion resistance,chemical properties stable,resist photooxidation aging,acid and alkali resistant,suiltable for different soil and soil conditions,such as desert;

3. Good lateral restrict and preven slippery,prevent deformation,effectively enhance the bearing capacity of subgrade and dispersed loads function;

4. The geocell height and welding distance etc. geometric dimensions are all changeable in order to meet the requirements of different projects;

Specifications of HDPE Geocell used in Road Construction

| Item | Geogrid Chamber | High Strength Geogrid |

| Tensile Strength of Sheet Materials Mpa | ≥23 | ≥200 |

| Tensile Strength of Weided Seam N/cm | ≥100 | ≥150 |

| Distance of Welding (mm) | 330-550 | |

| Stretched Size (m×m) | 4×5~6×7 | |

Applications of HDPE Geocell used in Road Construction

1. It has retractable, contractible fold when transportation, it can be tensioned reticulated when construction , fill dirt, gravel, concrete and other loose material , constitute a powerful lateral limits and great structure stiffness .

2. Light weight, wear resistance, chemical stability, light oxygen aging, acid, suitable for different soil and desert soil conditions.

3. Higher lateral restrictions and non-slip, anti-deformation, effectively enhance the load bearing capacity and decentralized subgrade.

4. Geocell change the height, distance and other weld geometries to meet different project needs.

5. Connection is convenient, fast construction speed

IMages of HDPE Geocell used in Road Construction

RFQ:

Q1:Can you provide a sample for us?

A:yes,we can provide for your free samples based on freight collect.

Q2:What is your MOQ?

A:MOQ is 10000sqm.

Q3:What is payment terms?

A:T/T,L/C

Q4:What is your lead time?

A:According to your order quantity,usually 7days for 1*40HC

Q5:Do the customized design accepted?

A:We welcome customized design.

- Q: Can geocells be used for temporary helipads in remote areas?

- Yes, geocells can be used for temporary helipads in remote areas. Geocells are lightweight, portable, and easy to assemble, making them suitable for quick deployment in remote locations. Their cellular design provides stability and load-bearing capacity, allowing helicopters to land and take off safely. Additionally, the geocell structure can withstand various weather conditions and erosion, ensuring the durability of the helipad in remote areas.

- Q: Can geocells be used for erosion control on riverbanks?

- Yes, geocells can be used for erosion control on riverbanks. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene, which can be filled with soil, aggregate, or vegetation. When installed on riverbanks, geocells provide stability, prevent soil erosion, and promote vegetation growth. They can effectively withstand the erosive forces of flowing water and help to reinforce the riverbank.

- Q: Can geocells be used for landfill capping?

- Yes, geocells can be used for landfill capping. Geocells are three-dimensional honeycomb-like structures made of high-density polyethylene (HDPE) material. They are commonly used for soil stabilization and erosion control applications. When used for landfill capping, geocells can provide a stable and protective barrier on top of the landfill, preventing the infiltration of water and minimizing the risk of soil erosion. Additionally, geocells can help distribute the load evenly and provide support for the capping layer, improving the overall integrity and longevity of the landfill cap.

- Q: How do geocells improve load transfer to surrounding soil?

- Geocells improve load transfer to surrounding soil by confining and stabilizing the soil particles within their interconnected cells, creating a stronger and more stable foundation. This confinement prevents lateral movement of the soil particles, increasing their shear strength and resistance to deformation under loads. Additionally, the geocells enhance the load distribution by spreading the applied load over a wider area, reducing localized stress concentrations and promoting a more uniform transfer of load to the surrounding soil.

- Q: Can geocells be used for railway embankment stabilization?

- Yes, geocells can be used for railway embankment stabilization. Geocells are cellular confinement systems that provide reinforcement and erosion control in various applications, including railway embankments. They help distribute load and prevent soil movement, thereby enhancing the stability and longevity of the railway embankment.

- Q: What are the applications of geocells in road construction?

- Geocells have numerous applications in road construction, including soil stabilization, erosion control, and pavement reinforcement. They are used to improve the load-bearing capacity of weak soils, prevent soil erosion, and provide a stable base for road construction. Geocells also help in reducing construction costs and increasing the longevity of roads by distributing the load uniformly and minimizing settlements.

- Q: What are the benefits of using geocells in oil and gas industry applications?

- There are several benefits of using geocells in oil and gas industry applications. Firstly, geocells provide a stable and durable foundation for infrastructure such as access roads, well pads, and pipelines. This helps in reducing maintenance costs and prolonging the lifespan of the infrastructure. Secondly, geocells help in controlling soil erosion and preventing sedimentation, especially in areas with steep slopes or unstable soil conditions. This minimizes the risk of environmental damage and ensures compliance with regulations. Additionally, geocells improve the load-bearing capacity of the soil, allowing heavy equipment and vehicles to operate safely in challenging terrains. This enhances overall operational efficiency and reduces the likelihood of accidents or equipment damage. Moreover, geocells can be easily installed and are highly adaptable to different site conditions, making them a cost-effective solution for temporary or remote oil and gas operations. They can be quickly deployed and removed as needed, minimizing construction time and reducing environmental disturbance. Overall, the use of geocells in the oil and gas industry offers numerous advantages including improved infrastructure stability, environmental protection, enhanced safety, and cost savings.

- Q: Can geocells be used in green roof construction?

- Yes, geocells can be used in green roof construction. Geocells are often employed as a stabilizing and reinforcing solution in various construction projects, including green roofs. They provide structural support and prevent soil erosion, allowing for the successful implementation of vegetation on the roof. Additionally, geocells help with water drainage and root protection, making them a suitable choice for green roof construction.

- Q: How do geocells prevent soil lateral movement?

- Geocells prevent soil lateral movement by confining and reinforcing the soil within a series of interconnected cells, which act as a barrier against horizontal forces. The cells provide structural stability and distribute the applied loads evenly, reducing the potential for soil displacement or sliding.

- Q: How are geocells used in erosion control?

- Geocells are used in erosion control by providing a stable and strong structure to reinforce soil and prevent erosion. They are typically filled with soil or aggregate material and placed on slopes or areas prone to erosion. The interconnected cells within the geocell system allow for proper drainage while reducing water flow velocity, thus minimizing soil erosion.

Send your message to us

CE Certified HDPE Geocells for Erosion Control in Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords