Geocells South Africa Shandong Yong Embellish HPDE Large Room Products

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geocell reinforced

Geocell reinforced

Products overview:

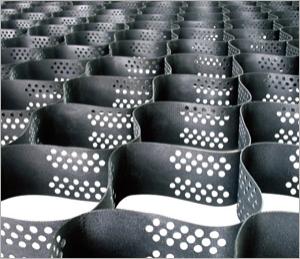

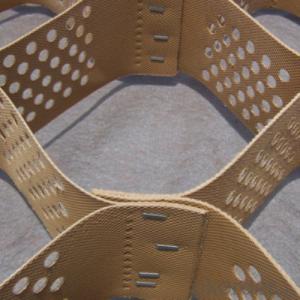

Shandong yongrun geocell reinforced by high intensity HDPE broadband, after strong welded together a mesh grid structure, it room retractile, transportation can shrink stack up, when using, open and and filling materials, or the concrete was a strong limit and the degree of lateral big just structures. It can be used to as a cushion, reinforcing soft increase the bearing capacity of the foundation, also can be laid in the slope surface slope protection structure form, can also be used to build a block structure, etc.

Product features:

1, material is qualitative light, wear resistance, stable in chemical, resistance to light oxygen aging, acid and alkali resistant, suitable for different soil and geological conditions of the desert, etc

2, higher lateral restrictions and prevent slippery, and preventing deformation, improve the bearing capacity of the roadbed and dispersed loads

3 and the higher the bearing capacity and good dynamic performance, resistance to erosion ability

4, change the geocell reinforced height, welding geometric size is to satisfy different needs of the project

5, retractile, transportation, small size, convenient connection, the construction speed is faster

6, when construction can use local materials, reduce the construction cost, easy to transport with composite

Application:

1, used for solid highway roadbed

2, used for solid railway roadbed

3, used to withstand heavy force of levee, retaining wall

4, used in shallow water river harnessing

5, designed to support the line and the drain

6, used to prevent landslides and heavy force by the hybrid retaining wall

7, for independent wall, wharf, levees, etc

8 on the highway, met in the soft foundation, the geocell reinforced can greatly reduce labor intensity, reduce thickness, roadbed construction speed is quick, good performance, greatly reduce the cost of projects

The product specification: TGLG5 TGLG8 TGLG10 TGLG15 TGLG20 (cm)

- Q: Can geocells be used for retaining walls in earthquake-prone areas?

- Yes, geocells can be used for retaining walls in earthquake-prone areas. Geocells are a type of cellular confinement system made from a honeycomb-like structure filled with compacted soil or aggregate. They provide excellent stability and reinforcement to the retaining wall structure, making them suitable for areas prone to seismic activity. The geocells distribute the forces generated during an earthquake more evenly, reducing the risk of wall failure and enhancing overall structural integrity.

- Q: Can geocells be used for wetland rehabilitation?

- Yes, geocells can be used for wetland rehabilitation. Geocells are three-dimensional cellular confinement systems that can provide structural support and stability to wetland areas. They can help prevent erosion, promote vegetation growth, and enhance the overall ecological function of wetlands. By confining soil and preventing its displacement, geocells create a stable foundation for wetland vegetation and can help restore and rehabilitate degraded wetland areas.

- Q: Can geocells be used for coastal revetment?

- Yes, geocells can be used for coastal revetment. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) materials. They can be filled with soil, sand, or concrete to create a stable and erosion-resistant structure. When used in coastal revetment, geocells provide additional protection against wave action, help to stabilize the shoreline, and prevent erosion.

- Q: Can geocells be used in agricultural applications?

- Yes, geocells can be used in agricultural applications. They are often used to stabilize soil, control erosion, and provide reinforcement for slopes in agricultural fields. Additionally, geocells can help in the construction of access roads and pathways, as well as in the establishment of green roofs and gardens in urban agriculture.

- Q: Can geocells be used in load support applications?

- Yes, geocells can be used in load support applications. Geocells are designed to provide stability and reinforcement to the ground, making them suitable for various load-bearing applications such as road construction, slope protection, and retaining walls. The interconnected cellular structure of geocells helps distribute the load evenly, improving the load-bearing capacity of the soil and preventing soil erosion.

- Q: Are geocells suitable for use in parking lot construction?

- Yes, geocells are suitable for use in parking lot construction. Geocells provide stability and reinforcement to the ground, reducing the potential for erosion, potholes, and uneven surfaces. They also allow for better load distribution, increasing the lifespan of the parking lot. Additionally, geocells are cost-effective and environmentally friendly, making them a practical choice for parking lot construction.

- Q: How do geocells help with ground improvement?

- Geocells help with ground improvement by providing a stable foundation and reinforcement to weak or unstable soils. They are three-dimensional, honeycomb-like structures made from high-density polyethylene (HDPE) or other materials. When filled with soil, geocells create a rigid mattress that distributes loads evenly and increases the bearing capacity of the ground. This helps prevent soil erosion, control lateral movement, and enhance the overall stability of the ground, making it suitable for construction, infrastructure, and erosion control projects. Additionally, geocells facilitate efficient drainage and promote vegetative growth, further aiding in ground improvement efforts.

- Q: Are geocells resistant to extreme temperatures?

- Yes, geocells are designed to be resistant to extreme temperatures and can withstand both hot and cold conditions without compromising their structural integrity.

- Q: How do geocells improve the performance of temporary access roads?

- Geocells improve the performance of temporary access roads by providing a stable and reinforced surface. They are made of a three-dimensional honeycomb structure that can be filled with various materials such as soil, gravel, or aggregate. This filling material locks into the cells, preventing it from shifting or eroding, even under heavy loads. This reinforcement increases the load-bearing capacity of the road, prevents rutting and erosion, and improves traction, making it suitable for heavy machinery and vehicles. Additionally, geocells distribute the load evenly, reducing stress on the underlying soil and minimizing the need for maintenance or repairs.

- Q: Are geocells resistant to seismic vibrations?

- Yes, geocells are generally resistant to seismic vibrations. The cellular confinement technology used in geocells provides stability and reinforcement to the underlying soil, making them effective in mitigating the effects of seismic activity.

Send your message to us

Geocells South Africa Shandong Yong Embellish HPDE Large Room Products

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords