HDPE Geocell with factory price for Load Support

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of HDPE Geocell

Geocell is made of HDPE reinforced sheet material, A three-dimensional mesh cell chamber formed by welding of high strength.Generally by the ultrasonic pin type welded together.Due to the need of engineering, some holes on the diaphragm.

Main Features of HDPE Geocell

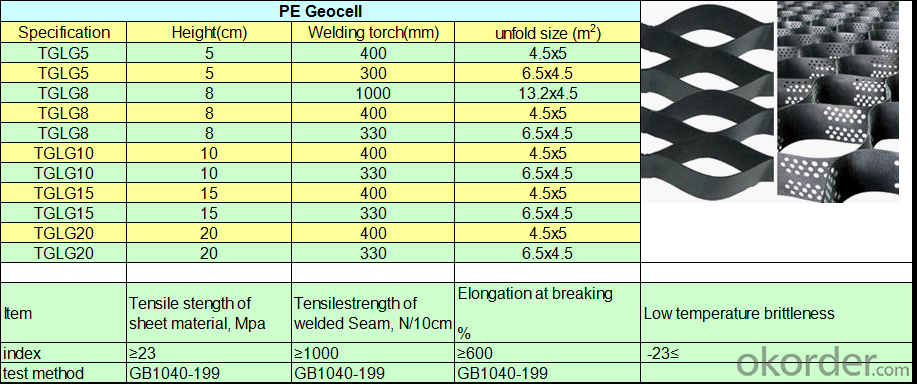

1.TGLG5 TGLG8 TGLG10 TGLG15 TGLG20(CM)

2.Stretch size :4mx5m or 6m x7m or at your request.

3. General roadbed reinforcement with 330 mm, 400 mm.

Slope protection with 500 mm, 660 mm

4.Executive standard:GB/T19274-2003

Specifications of HDPE Geocell

Applications of HDPE Plastic Geocell

1. processing half fill Semi roadbed

build up the embankment on the ground on the slopes of the natural slope ACTS in 1:5, supporting subsoil should dig the steps, The step width shall be less than 1 m, when building or rebuilding roads widened by installments, Convergence between the new and old roadbed fill slope ,should dig the step, high grade highway width is 2 m, laid large geocell in each of the steps horizontally, using the large geocell of their own facade confining reinforcement effect, better solve the problem of uneven settlement

2. subgrade in wind drift sand region

Sand subgrade should be given priority to with low embankment, region filling height not less than 0.3 m. generally due to its low subgrade, sand subgrade construction in professional requirements and heavy load, adopting large chamber loose packing confining effect, can be in limited the height of the roadbed with high stiffness and strength, to inherit the load stress of large vehicles.

3. Reinforced back subgrade soil

Using large geocell can better achieve the goal of abutment back reinforced , can generate enough friction between the geocell and packing . and effectively reduce roadbed uneven subsidence, finally can effectively relieve the abutment jump car "disease early impact damage of bridge deck.

4. subgrade in permafrost region

In permafrost regions fill roadbed construction, should reach a minimum filling height in order to prevent or cause a frozen layer ceiling Frothing decreased, resulting in an excess of embankment settlement occurs. Geocell unique overall unconfined facades reinforced effect and effectively implemented, can ensure a minimum filling height in some special area to the maximum extent, and to fill a high-quality strength and stiffness.

5. The collapsibility loess roadbed treatment

When the highway and the highway collapse loess and loess lot better compression by wet, or foundation bearing capacity is lower than the high embankment to allow third-party vehicle load and weight of pressure embankment, subgrade bearing capacity requirements should also for processing, then the superiority of Geocell on manifest is no doubt.

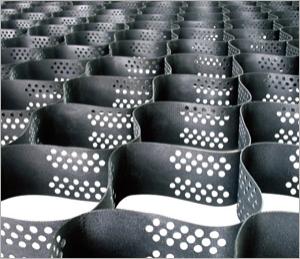

IMages of HDPE Geocell

RFQ:

Q1:Can you provide a sample for us?

A:yes,we can provide for your free samples based on freight collect.

Q2:What is your MOQ?

A:MOQ is 10000sqm.

Q3:What is payment terms?

A:T/T,L/C

Q4:What is your lead time?

A:According to your order quantity,usually 7days for 1*40HC

Q5:Do the customized design accepted?

A:We welcome customized design.

- Q: Can geocells be used in earthquake-prone areas?

- Yes, geocells can be used in earthquake-prone areas. Geocells are a type of cellular confinement system that can provide reinforcement and stability to soil and slopes. They can help mitigate the effects of seismic activity by confining and reinforcing the soil, improving its shear strength and resistance to liquefaction. Additionally, geocells can be used for retaining walls, embankments, and erosion control in earthquake-prone areas, making them a suitable solution for enhancing the stability and resilience of the ground in such regions.

- Q: What are the considerations for geocell design in cold climates?

- Some considerations for geocell design in cold climates include selecting materials with good cold weather performance, ensuring proper installation techniques to account for freezing and thawing conditions, and designing for increased load capacity due to snow accumulation. Additionally, incorporating proper drainage systems and addressing potential frost heave issues are important considerations in geocell design for cold climates.

- Q: Can geocells be used for recreational trail construction?

- Yes, geocells can be used for recreational trail construction. Geocells are a popular choice for building trails due to their ability to provide stabilization, erosion control, and increased load-bearing capacity. They are easy to install, cost-effective, and environmentally friendly, making them suitable for various recreational trail construction projects.

- Q: Can geocells be used in ground stabilization for pipelines?

- Yes, geocells can be used effectively in ground stabilization for pipelines. Geocells are three-dimensional cellular confinement systems made from high-density polyethylene (HDPE) material. They can be filled with various infill materials like soil, gravel, or aggregate. When installed beneath the pipeline, geocells provide structural support and prevent soil erosion or lateral movement, ensuring stability and longevity of the pipeline infrastructure.

- Q: How do geocells enhance the stability of cut slopes?

- Geocells enhance the stability of cut slopes by providing a reinforced and stabilized structure. The cellular confinement system of geocells helps to confine the infill material within the cells, preventing it from sliding or eroding. This confinement increases the shear strength of the fill material, reducing the potential for slope failure. Additionally, the interconnected cells distribute the load evenly, improving the overall stability and load-bearing capacity of the slope.

- Q: How do geocells improve soil stability?

- Geocells improve soil stability by confining and reinforcing the soil, preventing lateral movement and enhancing load-bearing capacity. The honeycomb-like structure of geocells provides a stable platform that distributes loads evenly, reducing soil erosion and promoting vegetation growth, ultimately enhancing the overall stability of the soil.

- Q: Can geocells be used for noise barrier fences?

- Yes, geocells can be used for noise barrier fences. Geocells are versatile and can be filled with various materials such as soil, sand, or gravel, which can effectively reduce noise transmission. Additionally, the cellular structure of geocells provides stability and support to the fence, making them suitable for noise barrier applications.

- Q: What are the factors affecting the selection of geocells for a project?

- Some factors that can affect the selection of geocells for a project include the load-bearing requirements of the project, the soil conditions at the site, the environmental factors such as temperature and moisture levels, the desired lifespan of the geocells, and the availability and cost of the materials. Additionally, the project's budget and timeline, as well as any specific design or aesthetic requirements, may also influence the selection of geocells.

- Q: Can geocells be used in slope greening projects?

- Yes, geocells can be used in slope greening projects. Geocells are three-dimensional honeycomb-like structures made from various materials, such as plastic or geotextiles, which are filled with soil or vegetation. They provide stabilization, erosion control, and support to slopes while promoting vegetation growth. Geocells can retain soil and water, prevent erosion, and create a stable base for plants to grow, making them suitable for slope greening projects.

- Q: How do geocells help with stormwater infiltration?

- Geocells help with stormwater infiltration by providing a stable structure that can be filled with permeable materials such as gravel or sand. These materials allow stormwater to infiltrate into the ground, reducing runoff and preventing excessive water accumulation. Additionally, geocells help to distribute the weight of the stormwater evenly, preventing soil compaction and facilitating better infiltration rates.

Send your message to us

HDPE Geocell with factory price for Load Support

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords