HDPE Geocell for Road Construction, Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1, Specification of Geo cell

1) Material : HDPE/PP/PE

2) Thickness :0.8,0.9,1.0,1.1,1.2mm

3) Height : 50,75,100,150,200,250,300mm

4) Certificate : CE/ISO9001,14001

2, Application of Geo cell

A. firm for the railway roadbed

In order to prevent gravel gradation lateral movement is stronger as a whole to prevent the pumping, even if the soft ground can prevent the collapse of the whole or in part, the large volume of traffic in areas such as the Cross Road, bifurcation Road and turn, can significantly increase the use of Number of years.

B. for a solid roadbed

Can generate high power and flexibility of both traditional and rock embankment on the basis compared to the basis of thickness can be reduced more than 50% of the gravity and contact with the pressure and reduce the horizontal dispersion and can be used when the account or on a permanent road construction .

C. used to bear the gravity of the dam wall

Strengthen the definition of gravel to form the structure of the body has to stop cross-cutting pressure, no matter slide and pool formation, can itself be supported by non-structural surface layer and the natural plant, or a vertical ladder-type design.

D. shallow water for river training

Three-direction grid to enhance the strength of avoid fill soil erosion and increase the load, can reduce the cost of construction of the shallow river and allow river traffic with the design and a variety of soil conditions.

E. support for the pipeline and sewer

To use a more solid foundation for the pipeline, the construction is simple, reducing the excavation, do not have to lay many rocks and avoid part landslide in the long run.

F. used to prevent landslides and heavy-duty force by the retaining wall mixed

Do not have to use the template structure can create a solid wall, and backfill side firmly into the price of one, even if the traditional structure of a variety of gravity is not available, fill materials can also significantly reduce the cost of the project.

G. independence for the strong terminals, such as dams room

Can be quickly wall structure independent from the independent wall, and the use of water in the granular to protect dam, or weir wall, if temporary facilities are to be removed also Geocell back at the pier or breakwater and other important coastal Also use a wide range

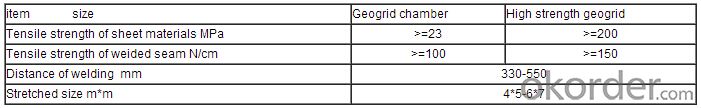

3,Technical data of Geo cell

4.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: How can the geotextile extension of 65 to do the following

- I professional production geotextile geomembrane and other geotechnical materials, wish smooth

- Q: What are the different geotextile installation techniques for landfill applications?

- There are several geotextile installation techniques used for landfill applications, including direct burial, slope installation, and liner attachment methods. Direct burial involves placing the geotextile directly on the ground or compacted soil, with subsequent layers of soil or waste material placed on top. Slope installation involves installing the geotextile on a slope, often using anchoring systems to secure it in place. Liner attachment methods involve attaching the geotextile to the liner system, which may include geomembranes, geocomposites, or other liner materials. These techniques are used to enhance the performance and stability of landfills by providing separation, filtration, and drainage capabilities.

- Q: How are geotextiles used in civil engineering?

- Geotextiles are used in civil engineering for various purposes such as soil stabilization, drainage, filtration, erosion control, and reinforcement. They are often employed to prevent soil erosion, improve soil strength, and enhance the overall stability of civil engineering structures like roads, embankments, and retaining walls. Geotextiles are also used in the construction of landfills, dams, canals, and coastal protection systems to provide effective filtration and drainage properties.

- Q: How do geotextiles help with filtration?

- Geotextiles help with filtration by preventing the passage of fine soil particles while allowing water to pass through. They act as a barrier, trapping sediments and contaminants, thus improving water quality and preventing soil erosion.

- Q: River slope protection geotextile unit area quality is generally how much

- Under normal circumstances is 100g - 1000g / square meter of the specifications, the actual situation is subject to special requirements, usually available geotextile unit area quality tester for testing, reference [standard group]. Test criteria: ASTM / D3776 / 2646, ISO3801, BS3424 / 2471, BSEN, M + SP65 / 65A, NEXT20

- Q: How do geotextiles reduce hydraulic pressure in soil?

- Geotextiles reduce hydraulic pressure in soil by allowing water to flow through them, while retaining soil particles. This helps to create a drainage pathway, preventing water buildup and reducing the pressure exerted on the soil.

- Q: Are geotextiles resistant to hydrolysis?

- Yes, geotextiles are generally resistant to hydrolysis.

- Q: Production of acupuncture carpets, geotextiles, warm flakes, paper blankets, air filter materials, the main raw material is what? why?

- The main raw material is polyester, polyester is the basic composition of polyethylene terephthalate, it is also known as polyester fiber (PET), the long chain of its chemical formula H (OCH2CCOCO) NOCH2CH2OH, the relative molecular weight is generally ~ The In fact, there are a small amount of monomer and oligomers present. These oligomers have a low degree of polymerization and are present in an annular form. Polyethylene terephthalate can be obtained by polycondensation of terephthalic acid (PTA) and ethylene glycol (EG) by direct esterification of ethylene terephthalate 9BHET. From the composition of polyester molecules, it is composed of short fatty hydrocarbon chain, ester, benzene ring, terminal alcohol hydroxyl group. Polyester molecules in addition to the existence of two hydroxyl groups, there is no other polar groups, and thus polyester fiber hydrophilic poor. Polyester molecules contain about 46% of the ester group, ester groups can be hydrolyzed at high temperatures, thermal cracking, the case of alkali is the saponification, the degree of polymerization reduced; polyester molecules also contain aliphatic hydrocarbon chain, it can make polyester molecules have a certain But because the polyester molecules can not rotate the benzene ring, so the polyester macromolecules are basically rigid molecules, molecular chains easy to maintain linear. Therefore, polyester macromolecules in this condition is easy to form crystals, so the polyester crystallinity and orientation is higher.

- Q: Geotextile drainage network and geotextile how to heat stick

- Geotextile and geotextile crimp part of the use of sewing or hot air welding. Hot air welding is the connection method of filament geotextile, that is, with the hot air gun on the connection of two pieces of cloth instantaneous high temperature heating, so that part of the molten state, and immediately use a certain external force to make it firmly together. In the case of wet (rain and snow) weather can not be hot adhesive connection, geotextile should take another method of a suture connection method, that is, with a dedicated sewing machine for two-wire suture connection, and the use of anti-chemical UV suture.

- Q: How do geotextiles help in stabilizing slopes for pipeline construction?

- Geotextiles help in stabilizing slopes for pipeline construction by providing reinforcement and erosion control. They are placed on the slope surface to prevent soil erosion and stabilize the soil particles. The geotextiles act as a barrier, allowing water to drain while retaining soil particles, thus reducing the risk of slope failure.

Send your message to us

HDPE Geocell for Road Construction, Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords