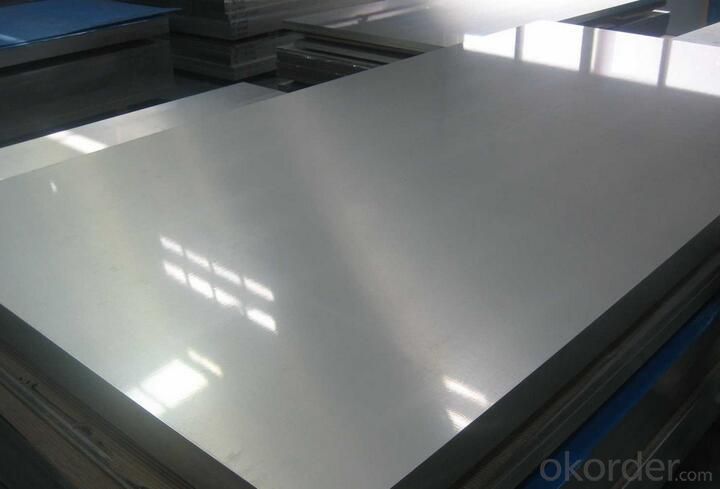

Adhesive Backed Aluminum Foil Sheets - 1200 h18 Mirror Finish Reflector Sheet for Lighting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1200 H18 mirror finish reflector sheet for lighting

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

Product Description

Goods name | Aluminum plate |

alloy | Yes |

Plance of origin | China |

Quality | Prime quality |

Certificate | ISO9001 |

Grade | 3000 Series |

Thickness | 0.3-150mm |

Type | Plate |

Width | 300-1950mm |

Model number | 3003,3004,3005,3014,3105 |

Surface | Mill finish |

Temper | O-H112 |

Ensure | we can supply customers' with different specifications of the highest quality and lowest price. Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit. |

- Q: What are the different methods for perforating aluminum sheets?

- There are several different methods for perforating aluminum sheets, each with its own advantages and applications. Some of the most common methods include: 1. Punching: Punching is one of the most traditional methods for perforating aluminum sheets. It involves using a punch and die set to create holes in the material. This method is efficient and cost-effective for producing simple hole patterns and is commonly used in industries such as automotive and construction. 2. Laser cutting: Laser cutting is a precise and versatile method for perforating aluminum sheets. It uses a high-powered laser beam to vaporize or melt the metal, creating intricate and complex hole patterns. This method is highly accurate, fast, and suitable for a wide range of applications, including decorative and functional perforations. 3. Waterjet cutting: Waterjet cutting is another popular method for perforating aluminum sheets. It uses a high-pressure jet of water mixed with abrasive materials to erode the metal and create holes. Waterjet cutting is known for its ability to cut through thick aluminum sheets and produce clean and precise edges. It is commonly used in industries such as aerospace and architecture. 4. Rotary perforating: Rotary perforating involves using a rotating cylindrical tool with sharp blades or teeth to perforate aluminum sheets. This method is ideal for producing continuous perforations or creating patterns that require curved or irregular hole shapes. Rotary perforating is commonly used in applications such as filtration systems and acoustic panels. 5. Pressing: Pressing, also known as embossing or stamping, is a method that involves pressing a patterned die into an aluminum sheet to create raised or sunken areas. These areas can act as perforations, providing aesthetic appeal or functional applications such as slip resistance. Pressing can be achieved using hydraulic or mechanical presses and is commonly used in industries such as architecture and interior design. It is worth noting that the choice of perforation method depends on various factors, including the desired hole pattern, material thickness, production volume, and budget. Consulting with a perforation specialist can help determine the most suitable method for a specific application.

- Q: How do you prevent warping of aluminum sheets during bending?

- One way to prevent warping of aluminum sheets during bending is by using proper techniques and tools. This includes using the correct bending radius, ensuring even distribution of pressure along the sheet, and employing a suitable clamping method to hold the sheet in place during the bending process. Additionally, preheating the aluminum sheet can help to reduce the likelihood of warping.

- Q: Is aluminum sheet resistant to UV rays?

- Indeed, aluminum sheet exhibits resistance to UV rays. By nature, aluminum develops a safeguarding oxide layer which functions as a shield against UV radiation. This protective layer aids in safeguarding the aluminum sheet from harm or deterioration caused by the sun's UV rays. Consequently, aluminum sheet proves to be an appropriate material for outdoor usage, enduring extended exposure to sunlight without experiencing fading or deterioration. Moreover, the reflective characteristics of aluminum also contribute to its resistance against UV rays, as it can effectively reflect a considerable portion of the sun's rays, diminishing heat absorption and the likelihood of damage.

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are suitable for signage applications. Aluminum is a lightweight and durable material, making it perfect for outdoor signs that need to withstand various weather conditions. It is resistant to rust and corrosion, which ensures the longevity of the sign. Aluminum sheets can be easily customized and cut into different shapes and sizes, allowing for versatile and creative signage options. Additionally, aluminum is a great material for digital printing and can provide high-quality graphics and images. Overall, aluminum sheets offer excellent durability, versatility, and aesthetic appeal, making them a popular choice for signage applications.

- Q: Can aluminum sheets be used for water tanks?

- Yes, aluminum sheets can be used for water tanks. Aluminum is a lightweight and corrosion-resistant material, making it suitable for storing water. It is commonly used in industries such as aerospace and marine due to its durability and ability to resist rust and corrosion. Aluminum tanks are also easier to transport and install compared to other materials, and they can withstand high pressure and extreme temperatures. However, it is important to ensure that the aluminum sheets used for water tanks are of high quality and meet the necessary standards to ensure the safety and longevity of the tank.

- Q: Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered. However, the process for each differs significantly. Welding aluminum typically involves using a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process, which requires a high heat source and a filler material to join the sheets together. The process can be more challenging compared to welding steel due to aluminum's high thermal conductivity and lower melting point. Soldering aluminum, on the other hand, is a process that involves using a low-temperature solder and flux to bond the sheets together. Specialized solders, such as aluminum solder or solder with a high percentage of tin, are typically used. Soldering aluminum is generally less common and more difficult compared to soldering other metals due to aluminum's oxide layer, which can prevent proper adhesion. In summary, while both welding and soldering can be used to join aluminum sheets together, welding is the more commonly used method due to its stronger and more durable results. Soldering aluminum can be more challenging due to the need for specialized solders and the presence of the oxide layer.

- Q: Can aluminum sheets handle high temperatures?

- Yes, aluminum sheets can handle high temperatures. Aluminum has a high melting point of 1220°F (660°C) and excellent heat transfer properties, making it suitable for various applications that involve exposure to high temperatures.

- Q: How do you prevent oxidation of aluminum sheets?

- To prevent oxidation of aluminum sheets, several methods can be employed. One common approach is to apply a protective coating or finish on the surface of the aluminum sheets. This coating acts as a barrier between the aluminum and the external environment, preventing the metal from reacting with oxygen and forming an oxide layer. There are various types of coatings available for this purpose, including anodizing, painting, and powder coating. Anodizing is a process that involves creating a controlled oxide layer on the surface of the aluminum through electrolysis. This oxide layer is highly resistant to corrosion and provides excellent protection against oxidation. Painting and powder coating involve applying a layer of paint or powdered polymer onto the aluminum surface. These coatings form a physical barrier that shields the metal from oxygen and moisture. Another effective way to prevent oxidation is by using aluminum alloys that have enhanced corrosion resistance. These alloys are specifically designed to have a higher resistance to oxidation and can withstand exposure to harsh environments without forming a significant oxide layer. In addition to coatings and alloy selection, proper storage and handling practices are crucial to prevent oxidation. Aluminum sheets should be stored in a clean, dry, and well-ventilated area to minimize exposure to moisture and corrosive elements. Any contact with acidic or alkaline substances should be avoided, as they can accelerate the oxidation process. Regular cleaning and maintenance of aluminum sheets also help in preventing oxidation by removing any contaminants that could promote corrosion. Overall, preventing oxidation of aluminum sheets involves a combination of protective coatings, appropriate alloy selection, and proper storage and handling practices. By implementing these measures, the lifespan and durability of aluminum sheets can be significantly improved.

- Q: Are aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are highly suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its excellent combination of strength, lightweight properties, and corrosion resistance. Its high strength-to-weight ratio makes it an ideal choice for constructing aircraft structures, including fuselages, wings, and other critical components. Aluminum sheets also offer good formability, allowing for complex shapes to be easily manufactured. Additionally, aluminum has good thermal conductivity, which is beneficial for heat dissipation in aerospace applications. Overall, aluminum sheets meet the stringent requirements of the aerospace industry and are extensively utilized in the construction of modern aircraft.

- Q: Are the aluminum sheets suitable for manufacturing heat exchangers?

- Indeed, aluminum sheets prove to be fitting for the production of heat exchangers. Aluminum, being both lightweight and highly conductive, serves as an ideal option for heat transfer purposes. Its exceptional thermal conductivity facilitates efficient heat transfer, resulting in effective cooling or heating procedures. Moreover, aluminum's resistance to corrosion is of utmost importance for heat exchangers that encounter diverse fluids. Furthermore, the malleability and formability of aluminum sheets render them effortlessly malleable into the required designs for heat exchanger components. On the whole, aluminum sheets offer numerous benefits for the manufacturing of heat exchangers, thus making them a suitable selection for this particular application.

Send your message to us

Adhesive Backed Aluminum Foil Sheets - 1200 h18 Mirror Finish Reflector Sheet for Lighting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords