10mm Aluminum Profiles According to the Standard American

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profiles Acoording to The Standard AmericanDescription:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profiles Acoording to The Standard American:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

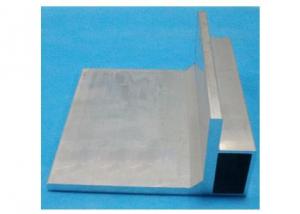

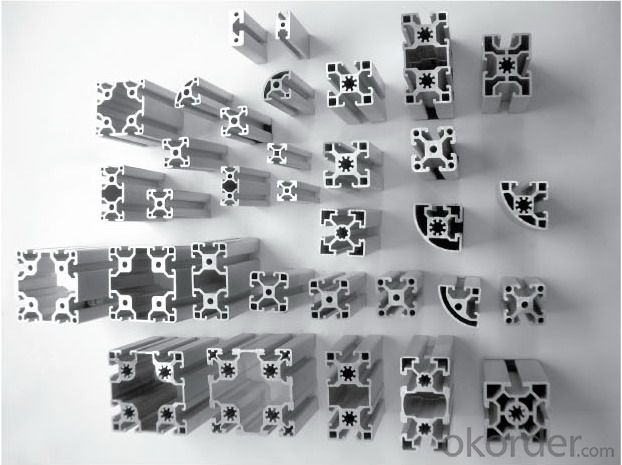

Images of the Aluminium Profiles Acoording to The Standard American:

Aluminium Profiles Acoording to The Standard American Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Profiles Acoording to The Standard American:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the standard dimensions and sizes of aluminum profiles?

- The dimensions and sizes of aluminum profiles can vary depending on the specific application and industry. However, there are commonly used dimensions and sizes that are widely adopted across industries. Aluminum profiles are available in various shapes, including angles, channels, tubes, and bars. These profiles have dimensions that range from small to large, with measurements based on width, height, and thickness. For instance, aluminum angle profiles typically have widths and heights ranging from 1/2 inch to 8 inches, with thicknesses ranging from 1/16 inch to 1/2 inch. Aluminum channel profiles have widths from 1/2 inch to 12 inches, heights from 1/2 inch to 3 inches, and thicknesses from 1/16 inch to 1/4 inch. Aluminum tube profiles come in different outer diameters, ranging from 1/8 inch to 6 inches, with wall thicknesses from 1/32 inch to 1/4 inch. Aluminum bar profiles usually have widths from 1/8 inch to 12 inches, heights from 1/8 inch to 4 inches, and thicknesses from 1/16 inch to 1/2 inch. It's important to note that these dimensions and sizes serve as a general guideline, and custom dimensions or sizes may be required for specific applications. Furthermore, different countries or regions may have their own standards and variations in aluminum profile dimensions and sizes. Therefore, it's advisable to consult with manufacturers or suppliers to determine the specific dimensions and sizes that meet your requirements.

- Q: Can aluminum profiles be used for electrical busbars?

- Yes, aluminum profiles can be used for electrical busbars. Aluminum is a commonly used material for busbars due to its high electrical conductivity, low cost, and lightweight nature. Aluminum profiles provide a reliable and efficient solution for electrical distribution in various applications, including power distribution systems, switchboards, and control panels. They offer good thermal conductivity, which helps in dissipating heat generated during high current flow. However, it is important to consider factors such as current carrying capacity, mechanical strength, and electrical insulation requirements while selecting aluminum profiles for busbar applications.

- Q: Can aluminum profiles be used in marine environments?

- Yes, aluminum profiles can be used in marine environments. Aluminum is often chosen for its excellent corrosion resistance and lightweight properties, making it ideal for marine applications. It is commonly used in the construction of boats, shipbuilding, and offshore structures due to its durability and ability to withstand exposure to saltwater and harsh weather conditions.

- Q: Can aluminum profiles be utilized in creating distinctive architectural designs and styles?

- <p>Yes, aluminum profiles can be used to create unique architectural designs and styles. They are favored for their strength, durability, and versatility. Architects can manipulate aluminum to achieve a wide range of shapes and structures, from sleek modern designs to traditional styles with a contemporary twist. Aluminum's lightweight nature and resistance to corrosion make it an ideal material for both interior and exterior applications, allowing for creative freedom in architectural expression.</p>

- Q: Light aluminum is what mean?

- Extruded out only through aging treatment, without other surface treatment of aluminum (such as spraying, oxidation and other deep-processing)

- Q: What is the limitation of aluminum bending

- General extrusion of aluminum quality is soft, over a period of time will be hardened, the longer the material more hard, no impact on the stretch bending, with hydraulic bending machine, there will be no cracks. Dongguan Sheng Hui Machinery Co., Ltd. to serve you. Thanks for taking it

- Q: This question seeks to understand the methods used to prevent rust and corrosion on aluminum profiles.

- <p>To prevent aluminum profiles from rusting and corroding, several methods can be employed: 1) Anodizing: This process creates a protective oxide layer on the aluminum surface, enhancing its resistance to corrosion. 2) Powder Coating: Applying a durable powder coating can protect the aluminum from moisture and other corrosive elements. 3) Regular Cleaning: Regularly cleaning the aluminum profiles can remove dirt and debris that may lead to corrosion. 4) Protective Films: Applying protective films or tapes can shield the aluminum from environmental factors that cause corrosion. 5) Proper Storage: Storing aluminum profiles in a dry, well-ventilated area can prevent moisture accumulation, which is a leading cause of rust. 6) Use of Corrosion Inhibitors: Applying corrosion inhibitors can slow down or prevent the chemical reactions that lead to corrosion. By implementing these measures, the lifespan and integrity of aluminum profiles can be significantly improved.</p>

- Q: Can aluminum profiles be used in noise insulation applications?

- Yes, aluminum profiles can be used in noise insulation applications. Aluminum profiles are versatile and can be designed to have excellent acoustic properties. They can be used to create soundproof windows, doors, walls, and enclosures. Aluminum profiles can be combined with materials like acoustic glass, rubber seals, and insulation foam to enhance their noise insulation capabilities. Additionally, aluminum's inherent strength and durability make it suitable for use in noise insulation applications as it can withstand the pressure and vibrations caused by sound waves. Overall, aluminum profiles offer a viable solution for noise insulation requirements in various settings, including residential, commercial, and industrial buildings.

- Q: What are the limitations of using aluminum profiles?

- Some limitations of using aluminum profiles include its relatively low strength compared to other metals like steel, making it less suitable for heavy-duty applications. It is also prone to corrosion in certain environments, requiring protective coatings or treatments. Additionally, aluminum profiles may not be as readily available or cost-effective in some regions compared to other materials.

- Q: Can aluminum profiles be used for creating display systems?

- Yes, aluminum profiles can be used for creating display systems. Aluminum profiles are lightweight, durable, and easy to work with, making them ideal for constructing various types of displays such as exhibition stands, trade show booths, and retail displays. They can be easily customized and allow for modular designs, enabling flexibility in creating unique and eye-catching display systems. Additionally, aluminum profiles offer a sleek and professional appearance, making them a popular choice in the display industry.

Send your message to us

10mm Aluminum Profiles According to the Standard American

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords