1. Pre-Painted Galvanized/Aluzinc Steel Coil China Best

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Pre-Painted Galvanized/Aluzinc Steel Coil China Best

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

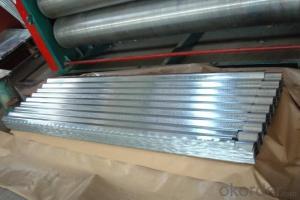

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

coil ID: 508/610mm

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: You have two steel wool pads,one is cut up into little pieces, and the other is whole, and they are both submerged in water. 1.Which steel wool pad will rust quicker?2.How much faster will that pad rust? (estimate+explain the estimate)6.How could you make the steel wool pad rust faster?Please dont tell me to do my homework because I tried, but I bought the wrong type of steel wool

- How to make it rust faster ? Adding oxygen to the water - bubbling air through it. Raising the temperature should make the reaction go faster, but I believe it also reduces the amount of dissolved gas. Adding salt, or an ionic compound like an acid, will accelerate electrochemical corrosion. That usually requires a less active metal, like copper, in contact with the steel, but variations in the composition of the steel may be sufficient to promote corrosion.

- Q: i see a lot of connexes say repair only with corten steel. what is the difference between corten steel and regular steel. and if i was going to stick weld it what type of electrode would i use?and while i'm at it what is the best electrode to use when welding galvenized steel?

- 6010 and 6011 Electrodes for welding galvenized steel. Weathering steel, best-known under the trademark COR-TEN steel and sometimes written without the hyphen as Corten steel, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. The corrosion-retarding effect of the protective layer is produced by the particular distribution and concentration of alloying elements in it. The layer protecting the surface develops and regenerates continuously when subjected to the influence of the weather. In other words, the steel is allowed to rust in order to form the 'protective' coating. For welding corten steel: 1A.W.S ClassificationE 7018 - 1AWS A 5 - 1 - 78 2IS classificationE 5424 JXIS 814 (Part I II)H 3BS classificationE 51.54 B 12 17HBs 639 - 1976

- Q: it isn't a SIGG water bottle or any other brand, as it's from thingsengraved what I'm wondering is, is this just as good as a SIGG water bottle, or is there any difference?

- Stainless steel is one of the best products to use for anything associated with food. It can be sterilized, it won't stain or absorb odors, it can be recycled and much of it is made of recycled material. If you take care of it, it can last a lifetime. We get hung up on brand names, you should look at the material it is made of. Which is a quality grade of stainless steel. I couldn't find the grade on the Sigg site, but I would think it would be the same or very similar. So, all that to say, this one seems to be as good as a Sigg.

- Q: How are steel coils used in the production of industrial valves?

- Steel coils are used in the production of industrial valves as they are typically cut and formed into various components, such as valve bodies and stems. The coils provide a strong and durable material for the valves, ensuring their reliability and longevity in industrial applications.

- Q: case hardening steel is adviced or thru hardening steel is most suitable?

- I don't know your application, but here is some advice. Case hard provides a hard shell around soft steel, depending on the bake, the case is usually .002-.008 thick. (thousands of an inch) Heat treated steel or tool steel is hard all the way thru. Case hardening, provides toughness with flexibility, however, once it's compromised, the part is scrap. Hardend tool steel is extreemly hard throughout and the harder it is, the more brittle it becomes. The application of the part will help you to determine the material needed. For instance; Plastic injection molds are very hard so the hot plastic wont erode them over years of use. Punch Press dies aren't as hard but are tougher to withstand the shock. Machine bolts are case hardened so they can last, but soft enough to allow some stretching during tightening. Either way, the time in mfg will be about the same. Most tool steels today cut like cheese, but take time to be heat treated. Tool steel will cost a bit more than low carbon steel. Low carbon steel is as machinable, and cheaper, but, again, the baking period is as long or longer than tool steel. There are a lot of materials on the market today that maintain the durability of heatreated steel without having to go thru that process. 4140, ( or chrome/moly) comes to mind. There are also some 400 series stainless that work as well, and others. You need to determine strength, flexibility, ease of mfg, cost and repairability when considering which steel to use.

- Q: I just want regular steel, not stainless steel.

- Iron is the primary ingredient in steel. All Steel is an alloy by definition. Stainless steels are alloys that resist corrosion. There are dozens of alloys of steel. Many stainless steels are not magnetic. If a magnet won't stick to it it is very likely to be a stainless steel but that is not true for all stainless steels. You really do need to be more specific as to what you want and why. There are too many to chose from.

- Q: what is the refining process doing to raw materials in steel

- The refining process removes impurities. Impurities are anything that is not iron (Fe). Most steels are at least 98% iron, with a fraction of a percent of carbon, a dash of manganese, and traces of sulphur and phosphorus. These are called carbon steels. The non-iron elements are impurities found with the iron in the ore. A certain amount of carbon and manganese is beneficial to the strength of steel, so part of the refining process is designed to control the carbon and manganese content to give desired properties to the steel. Sometimes small amounts of these are added in the process. Besides the common carbon steels, there are many alloys of steel in use today. Alloying is done after the steel is refined to over 98% iron, and while it is a liquid. Various elements are added to the steel in controlled amounts to give it special properties. These include silicon, aluminum, magnesium, vanadium, beryllium, nickel and chromium, and sometimes molybdenum, tungsten and titanium. Alloy steels are still mostly iron, ususally at least 95%, but some stainless steels are only 75% iron because of large amounts chromium and nickel added to the mix.

- Q: I'm in the middle of a remodel and buying appliances. Is there any way to ensure that the stainless steel is the same tone if you get different brands?

- it doesn't really matter. I have all appliances in my kitchen stainless steel. All different makes never noticed the tone, I think it just depends on the grain. i clean my appliances side to side not up and down. Good question never thought about that.

- Q: How is the demand for steel coils influenced by the construction sector?

- The construction sector heavily influences the demand for steel coils. These coils are essential in construction as they are used for various purposes such as structural framework, roofing, fencing, and reinforcement. There are several factors that drive the construction sector's demand for steel coils. Firstly, as the construction industry grows and expands, the need for steel coils increases to meet the rising demand for new infrastructure, commercial buildings, and residential properties. This includes the construction of bridges, highways, airports, office complexes, residential towers, and more. Secondly, the demand for steel coils in the construction sector is influenced by economic conditions. When the economy is performing well and there is increased investment in construction projects, the demand for steel coils tends to rise. Conversely, during economic downturns or recessions, the construction sector slows down, resulting in a decrease in demand for steel coils. Furthermore, changes in construction techniques and advancements in technology also impact the demand for steel coils. As new construction methods and materials are introduced, the use of steel coils may increase or decrease depending on their compatibility and effectiveness in these new applications. For example, the popularity of pre-engineered steel buildings has led to an increased demand for steel coils. Government policies and regulations also play a crucial role in shaping the demand for steel coils in the construction sector. Government initiatives promoting infrastructure development, sustainable construction practices, or energy-efficient buildings can significantly impact the demand for steel coils. For instance, incentives for green buildings may drive the use of steel coils in construction projects aiming for LEED certification. In conclusion, the demand for steel coils is tightly connected to the construction sector. Economic conditions, construction activity, technological advancements, and government policies all influence the demand for steel coils in the construction industry. Understanding these factors is crucial for steel manufacturers and suppliers to effectively meet the needs of the construction sector.

- Q: Can steel coils be coated with magnetic materials?

- Yes, steel coils can be coated with magnetic materials.

Send your message to us

1. Pre-Painted Galvanized/Aluzinc Steel Coil China Best

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords