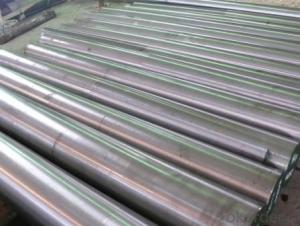

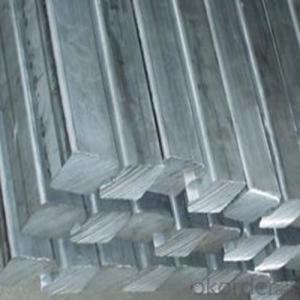

Stainless Steel Square Bar

Stainless Steel Square Bar Related Searches

H S Code For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Step Bit For Stainless Steel Transformers For Lights In Ceiling Led Lamps For Ceiling Stainless Steel Box With Lid Stainless Steel Bucket With Lid Ceiling Plate For Hanging Light Decorative Lights For CeilingHot Searches

Steel Mesh Panels For Sale Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Aluminum Bar Stock For Sale Bags Of Cement For Sale Types Of Temporary Side Panels For Cement Deck Cost Of Awnings For Decks Type Of Scaffolding With Pdf Price Of Scrap Stainless Steel Price Of Stainless Steel Scrap Price Of Stainless Steel Galvanized Steel Scrap Price Type Of Stainless Steel Types Of Stainless Steel Grades Types Of Stainless Steel Aluminum Corp Of China Stock Types Of Scaffolding In Construction Pdf Stainless Steel Factory Stainless Steel TypeStainless Steel Square Bar Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Square Bar supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Square Bar firm in China.Hot Products

FAQ

- Yes, a steel square can be used for measuring angles in metal fabrication. Steel squares have a 90-degree angle and typically include additional angles such as 45 and 30 degrees, which make them suitable for measuring and marking angles accurately in metal fabrication.

- Certainly! Deck railing installation can indeed make use of a steel square. This multipurpose tool, known as a steel square, is highly adaptable and finds utility in a wide range of construction and carpentry tasks. One such task is the installation of deck railings. Thanks to its straight edges and right-angle corners, the steel square becomes an invaluable aid in accurately measuring and marking precise angles. This ensures that the railing is aligned and level as it should be. Moreover, the steel square's durability and strength make it perfectly suited for withstanding the forces and weight that deck railings must bear. However, it is worth mentioning that a complete and secure installation may require the use of other tools and materials, including screws, brackets, and a drill.

- The purpose of a steel square, also known as a framing square or carpenter's square, is to assist in the construction and layout of right angles. It is a versatile tool used by carpenters, woodworkers, and other tradespeople to measure, mark, and cut various angles and lengths accurately. A steel square typically consists of two arms, a long one called the blade and a shorter one called the tongue. These arms are joined at a 90-degree angle, forming a precise right angle. The blade is marked with various measurements and angles, allowing for precise calculations and layout. One of the primary uses of a steel square is to determine and mark right angles. By aligning the blade and tongue against the edges of a board or a wall, a carpenter can ensure that the corners are perfectly square. This is crucial for constructing frames, rafters, stairs, and other structures that require precise angles. Furthermore, a steel square can be used to measure and mark angles other than 90 degrees. By utilizing the marked angles on the blade, one can easily measure and cut common angles like 45 degrees or 30 degrees. This makes it a valuable tool for tasks such as mitering corners, making bevel cuts, or creating accurate angles in woodworking projects. Overall, the purpose of a steel square is to provide a reliable and efficient way to establish and work with right angles and various angles in construction and woodworking. It helps ensure accuracy, efficiency, and quality in the process of measuring, marking, and cutting, making it an indispensable tool for professionals and hobbyists alike.

- The levelness of a workbench top can be checked using a steel square. This versatile tool allows for various measurements and alignments, making it ideal for this task. To check the levelness, simply position the steel square on different sections of the surface and observe if it rests evenly or reveals any gaps. If the square lays flat without any gaps, it signifies a level workbench top. However, if there are gaps or unevenness, adjustments should be made to ensure a level surface.

- In order to mark stair stringers using a steel square, several steps must be followed. Begin by determining the total rise and run of the stairway. The rise denotes the vertical distance from the floor to the top of the landing or upper floor, while the run represents the horizontal distance from the front edge of one step to the next. After obtaining these measurements, position the steel square on the edge of a piece of lumber that will serve as the stringer. Ensure that the long edge of the square is aligned with the lumber's edge, and that the shorter arm of the square is directed towards the top of the stringer. Then, utilize the rise and run measurements to mark the stringer. For the rise, locate the corresponding number on the long edge of the steel square and draw a line across the lumber. This line signifies the top of each step. For the run, locate the measurement on the shorter arm of the square and draw a parallel line to the previously marked top line. This line indicates the front edge of each step. Reiterate this process for each step, maintaining consistent measurements for both rise and run. It is important to thoroughly check the measurements for consistency in order to ensure a level and properly aligned stairway. Once all the steps have been marked on the stringer, employ a circular saw or handsaw to cut along the marked lines. Take care and cut with precision, as accuracy plays a crucial role in creating a safe and stable stairway. Lastly, test fit the stringer in place to confirm proper fitting. If necessary, make any adjustments before proceeding with the stair installation. While marking stair stringers with a steel square may require practice, it ultimately becomes a dependable and efficient method for accurately marking and cutting stringers.

- Yes, a steel square can be used for measuring roof pitch. A steel square, also known as a framing square or carpenter's square, is a versatile tool used in carpentry and construction. It has a long blade and a shorter tongue, forming an L-shape. The blade of the square is marked with various angles and measurements, making it useful for determining roof pitch. To measure the roof pitch using a steel square, you can place the longer blade of the square along the roof rafters or trusses, ensuring that it is aligned with the bottom edge of the roof. Then, you can adjust the angle of the square until the shorter tongue rests on the roof surface. By reading the measurement on the blade where it intersects the desired pitch, you can determine the roof pitch accurately. The steel square's ability to measure angles and pitch makes it a reliable tool for determining roof slope and ensuring proper installation of roofing materials. However, it is essential to note that using a steel square may require some knowledge and practice to obtain accurate measurements. Additionally, other specialized tools, such as a digital inclinometer or a laser level, may provide more precise measurements for roof pitch in certain circumstances.

- In order to measure and mark obtuse angles using a steel square, a few steps must be followed. Begin by ensuring that the steel square is clean and free from any dirt or debris that could impact its precision. Then, place the steel square flat onto the surface or material that needs to be measured and marked. Next, locate the 90-degree angle on the steel square, which is formed by the intersection of the longer side (blade) and the shorter side (tongue). This point is typically indicated by a right angle symbol (∠). To measure an obtuse angle, the steel square must be opened wider than 90 degrees. Gradually open the steel square by pivoting the tongue away from the blade until the desired angle is reached. It is important to keep the blade edge flush with the working surface or material. Once the steel square has been opened to the correct angle, firmly hold it in place and use a pencil or marker to mark the desired point on the material. The blade edge can also serve as a guide for drawing a straight line. To verify the accuracy of the marked obtuse angle, a protractor can be used to measure the angle precisely. This will ensure that the measurements are correct and the obtuse angle is accurately marked. Remember to handle the steel square with caution and avoid applying excessive pressure, as this could impact its precision. With practice and attention to detail, a steel square can be effectively used to measure and mark obtuse angles.