Steel Bar of Square Shape for Deformed Steel Bar Fabrication

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Bar of Square Shape Description:

Steel bar of square shape is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, steel bar of square shape is still in the form of a metal bar or rectangle. Small sizes of steel bar of square shape are used in ship building.

2. Main Features of Steel Bar of Square Shape:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

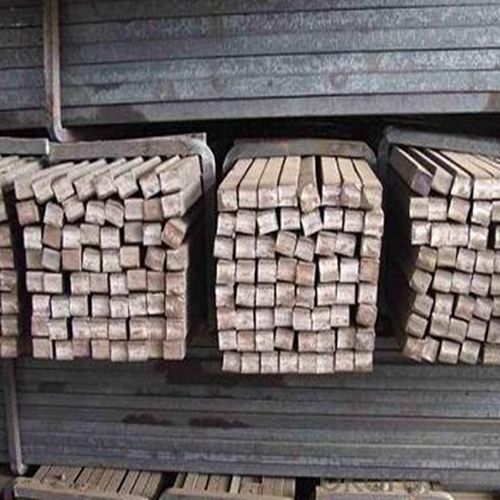

3. Steel Bar of Square Shape Images:

4. Square Bars with Firm Sides Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:Can a steel square be used for checking the flatness of a wall stud?

- Using a steel square for examining the flatness of a wall stud is not possible. A steel square serves as a measuring tool mainly utilized for marking and measuring right angles. It is not intended to evaluate the evenness or straightness of a surface. To assess the flatness of a wall stud, a straightedge or level must be employed. These instruments offer a higher level of precision and can identify any abnormalities or deviations in the surface.

- Q:What are some common features of steel squares?

- Steel squares possess several common characteristics, including: 1. Material: Crafted from high-quality steel, these squares exhibit exceptional durability and strength. 2. Shape: Typically resembling a right-angled triangle, steel squares possess one elongated side and two shorter sides that form a perfect 90-degree angle. 3. Precision: Meticulously engineered, steel squares guarantee precise measurements and angles. Their edges and corners undergo meticulous machining to deliver consistent and accurate results. 4. Markings: Often adorned with markings along their edges, steel squares offer users the ability to measure and indicate specific lengths or angles. 5. Graduations: Some steel squares are embellished with engraved or printed scales, allowing for easier measurement of angles or distances. 6. Versatility: Steel squares serve a multitude of purposes, including measuring, marking, and verifying right angles, as well as determining and transferring angles. 7. Size and weight: Steel squares are available in various sizes, ranging from compact pocket-sized squares to larger ones designed for heavy-duty applications. The weight of a steel square varies depending on its size and thickness. 8. Corrosion resistance: To prolong their lifespan, steel squares are often treated or coated to enhance their resistance to rust and corrosion. 9. Stability: Engineered for stability and rigidity, steel squares provide a dependable reference point for precise measurements and layout work. 10. Multi-functionality: Certain steel squares may incorporate additional features, such as built-in spirit levels, scribing tools, or adjustable components, offering enhanced versatility and convenience for specific applications.

- Q:Can a steel square be used for furniture making?

- Yes, a steel square can be used for furniture making. A steel square, also known as a framing square or a carpenter's square, is a versatile tool that is commonly used in woodworking and construction. While it is most commonly associated with checking right angles and laying out framing, it can also be used in furniture making. When making furniture, precision and accuracy are crucial, and a steel square can help achieve these. It can be used to ensure that corners are perfectly square, angles are accurately measured, and pieces are properly aligned during assembly. Additionally, a steel square can be used to mark straight and parallel lines, aiding in the layout and design process. While traditional woodworking squares made of wood or aluminum are more commonly used in furniture making, a steel square offers several advantages. It is more durable and resistant to wear and tear, ensuring longevity and accuracy over time. Steel squares are also typically more precise, thanks to their machined edges and accurate measurements. It is important to note that furniture making often involves working with different types of materials, such as wood, metal, or even glass. In these cases, a steel square is particularly useful as it can handle the rigors of working with various materials. In conclusion, while a steel square may not be the most commonly used tool in furniture making, it can certainly be a valuable addition to a woodworker's toolkit. Its versatility, durability, and accuracy make it a reliable tool for ensuring precise measurements, right angles, and proper alignment during the construction of furniture.

- Q:Can a steel square be used for checking the squareness of a table top?

- Yes, a steel square can be used to check the squareness of a table top. A steel square is a reliable tool that can help ensure that the corners and edges of the table top are perfectly perpendicular to each other, thus confirming its squareness.

- Q:How do you use a steel square for making precise 45-degree angle cuts?

- To use a steel square for making precise 45-degree angle cuts, follow these steps: 1. Start by ensuring that your steel square is clean and free from any debris or rust. This will help maintain accuracy during the cutting process. 2. Place your steel square on the material you wish to cut, ensuring that the longer side of the square is aligned with the edge of the material. For example, if you are cutting a piece of wood, align the square with the edge of the wood. 3. Hold the square firmly in place, making sure it doesn't move while you're working. 4. To create a 45-degree angle cut, you need to position the material at a specific angle against the square. For this, you can use the inner corner of the square as a guide. Align one of the edges of the material with the inner corner of the square. This will create a 45-degree angle between the square and the material. 5. Once you have the material properly aligned, use a pencil or a marking tool to trace along the edge of the square. This will create a precise line indicating where the cut should be made. 6. After marking the line, carefully remove the square and reposition it out of the way. Ensure that the material is secure and won't move during the cutting process. 7. Use an appropriate cutting tool such as a saw or a miter saw to cut along the marked line. Make sure to follow proper safety precautions and use the appropriate cutting technique for the tool you are using. 8. Take your time while cutting, ensuring that you follow the marked line accurately. Cutting slowly and steadily will help maintain precision and avoid any mistakes. By following these steps, you can effectively use a steel square to make precise 45-degree angle cuts. Remember to always measure and mark accurately, and use appropriate cutting tools to achieve the desired results.

- Q:Can a steel square be used for setting up a scroll saw?

- Yes, a steel square can be used for setting up a scroll saw. A steel square is a versatile tool that can be used for various woodworking tasks, including setting up a scroll saw. It can be used to ensure that the scroll saw's table is perfectly perpendicular to the blade, ensuring accurate and precise cuts. The steel square can be placed against the blade and the table, allowing the user to adjust the table's angle until it is perfectly square. This will help in achieving straight and clean cuts while using the scroll saw.

- Q:What are the markings and graduations on a steel square used for?

- The markings and graduations on a steel square are used for a variety of purposes in carpentry and other related fields. Firstly, the markings are used to measure and mark specific lengths on the material being worked on. The square typically has both imperial and metric measurements, allowing for precise and accurate measurements in either system. These markings help ensure that cuts and joints are made at the correct dimensions, resulting in a more precise and professional finish. Additionally, the graduations on a steel square are used for angle measurements. The square typically has a protractor scale, which allows for the measurement of angles from 0 to 180 degrees. This is particularly useful for tasks such as creating angled cuts or marking out specific angles for joinery work. Furthermore, the square often has additional markings and features that aid in various tasks. For example, it may have a scale for finding the center of a circle or a ruler edge for quick measurements. Some squares also have scribe lines, which can be used to mark parallel lines or reference points. Overall, the markings and graduations on a steel square are essential tools for accurate measurements, angle markings, and various other tasks in carpentry and related fields. They help ensure precision and efficiency, resulting in better quality workmanship.

- Q:How do you use a steel square to mark a line perpendicular to an edge?

- To use a steel square to mark a line perpendicular to an edge, place one arm of the square against the edge of the material. Ensure that the other arm is parallel to the edge you want to mark the line on. Then, with a pencil or marker, trace along the perpendicular arm of the square to create a straight line that is perpendicular to the original edge.

- Q:How do you use a steel square for creating accurate bevel cuts?

- Achieving precise bevel cuts requires following a series of steps when utilizing a steel square. To begin, it is crucial to guarantee that the steel square is clean and devoid of any dirt or debris that may impact its accuracy. Next, establish the desired angle for the bevel cut. This can be accomplished by either employing a protractor or referencing a bevel angle guide or template. Once the angle is determined, position the steel square on the material that is to be cut, aligning one edge of the square with the material's edge. Subsequently, utilize a pencil or scribe to mark a line along the edge of the steel square. This line will serve as a guide for the bevel cut's trajectory. After marking the line, carefully position the saw blade at the starting point of the line, ensuring that it aligns precisely with the marked path. Securely hold the steel square against the material, employing it as a guide, and initiate the bevel cut along the marked line, maintaining a steady hand and applying consistent pressure against the steel square to ensure accuracy. Upon completing the cut, verify the angle using a measuring tool to ensure it aligns with the desired bevel angle. By adhering to these steps and utilizing a steel square as a guide, precise bevel cuts can be accomplished with confidence and precision.

- Q:Can a steel square be used for checking the alignment of tiles?

- Yes, a steel square can be used for checking the alignment of tiles. A steel square is a versatile tool that is commonly used in carpentry and tile work. Its straight edges and right angles make it ideal for ensuring that tiles are properly aligned and level. By placing the steel square against the edges of the tiles, one can easily determine if they are aligned correctly and make adjustments if needed. Additionally, the steel square can also be used to check the corners of the tiles, ensuring that they form perfect right angles. Overall, a steel square is a reliable tool for checking tile alignment and can help achieve a professional and aesthetically pleasing result.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Bar of Square Shape for Deformed Steel Bar Fabrication

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords