Carbon Structural Steel Square Bars S10C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

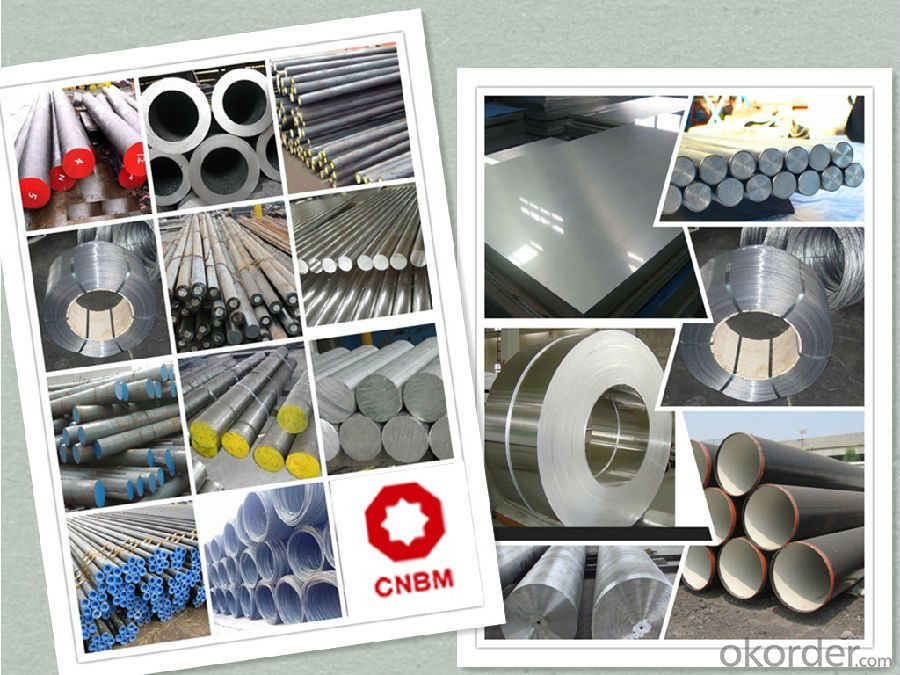

Carbon Structural Steel Square Bars S10C Specification 1, Size: 120*120mm; 130*130mm; 150*150mm; 160*160mm; 200*200mm 2, Length: Max 12m 3, Heat Treatment: Normalizing, Annealing, Tempering, Quenching 4, Surface Treatment: Black, Polished, Galvanized Chemical Composition % Mechanical Properties Strength of Extension Reduction of Area Products Show C Si Mn P S Cr Ni Cu 0.08-0.13 0.15-0.35 0.30-0.60 ≤0.030 ≤0.030 ≤0.20 ≤0.25 ≤0.25 Yield Strength Elogation Hardness ≥335(34) Mpa ≥205(21) Mpa ≥31% ≥55% ≤137HB

Work Shop

About Us

- Q:Can a steel square be used for insulation installation?

- No, a steel square cannot be used for insulation installation. Steel squares are typically used in construction and woodworking for measuring and marking right angles. Insulation installation requires materials that can provide thermal resistance, such as fiberglass, foam board, or mineral wool. These materials are specifically designed to trap air and prevent the transfer of heat, which steel squares are not capable of doing. Therefore, it is important to use appropriate insulation materials for effective insulation installation.

- Q:What are some common uses of a steel square in welding?

- A steel square, a versatile tool widely used in welding, has numerous applications. Some common uses of a steel square in welding include the following: 1. Ensuring Right Angles: The primary purpose of a steel square is to guarantee that welded joints are perfectly right angles, thus maintaining the structural integrity of the workpiece. 2. Accurate Measurement and Marking: With graduated scales along their edges, steel squares enable welders to measure and mark different lengths precisely. This ensures precise dimensions for welded components. 3. Layout and Pattern Creation: Steel squares are often employed in layout work to mark and create patterns, templates, and cut lines on metal surfaces. They allow welders to create perpendicular lines, parallel lines, and scribe circles and arcs. 4. Alignment Checking: Steel squares are handy for checking the alignment of welded components. Whether it's ensuring perfect alignment before welding or checking the alignment of a welded joint, a steel square ensures accurate alignment. 5. Checking Flatness and Squareness: Welders frequently use steel squares to verify the flatness and squareness of welded surfaces. By placing the square against the surface or weld, they can determine if the area is flat or if the edges are square. 6. Setting Up Welding Tables: Steel squares are useful for aligning and squaring the framework of welding tables, ensuring a stable and level surface for welding operations. 7. Fabrication and Assembly: Steel squares are commonly employed in the fabrication and assembly of welded structures. They aid in positioning and aligning components during the welding process, resulting in accurate and strong welds. In conclusion, a steel square is an indispensable tool in a welder's arsenal, providing accuracy, precision, and reliability for various welding applications.

- Q:What are some common uses for a steel square in woodworking?

- The steel square, also referred to as a framing square or carpenter's square, is a versatile instrument that serves many purposes in woodworking. Below are some common applications where the steel square proves to be useful: 1. Verification of right angles: The primary function of the steel square is to guarantee precise right angles in woodworking projects. It assists in squaring corners, ensuring that joints and edges meet precisely at 90-degree angles. 2. Marking and measuring: The square possesses a ruler along its blade, enabling woodworkers to measure and mark accurate lengths and dimensions. It is particularly advantageous for marking parallel lines, creating straight edges, or transferring measurements. 3. Determination of angles: The blade of the square contains markings for various degree angles, such as 45 degrees and 30 degrees. These markings can be utilized by woodworkers to determine and mark specific angles required for tasks like miter cuts or bevels. 4. Machinery setup: Woodworkers frequently utilize steel squares to align and set up machinery in woodworking workshops. They can be employed to ensure that tools such as table saws, jointers, and planers are correctly aligned for precise and safe operation. 5. Verification of squareness: When assembling cabinets, furniture, or other woodworking projects, a steel square can be utilized to verify squareness throughout the construction process. By measuring diagonals or checking the alignment of components against the square, woodworkers can ensure that their projects are properly squared. 6. Layout of stairs and rafters: Steel squares are invaluable when laying out stairs or designing roof rafters. They assist in determining the angle and length of cuts required to create properly fitting components. 7. Verification of flatness: Woodworkers can utilize a steel square to check for flatness on boards or surfaces. By placing the square against the wood, they can identify any gaps or unevenness that need to be addressed. In conclusion, the steel square is an essential tool in woodworking that aids in ensuring accuracy, precision, and proper alignment in various woodworking tasks.

- Q:Can a steel square be used for checking the verticality of a wall?

- No, a steel square cannot be used for checking the verticality of a wall. A steel square, also known as a framing square, is a tool primarily used in carpentry for measuring angles and making straight cuts. It is not designed or calibrated to determine verticality. To check the verticality of a wall, a level or plumb bob is typically used. A level is a tool with a bubble vial that helps indicate if a surface is perfectly vertical or horizontal. Plumb bobs, on the other hand, consist of a weighted string that hangs from a fixed point. By observing the alignment of the string with a reference point, one can determine if the wall is perfectly vertical. These tools are specifically designed for vertical measurements and provide more accurate results compared to a steel square.

- Q:How do you use a steel square to mark parallel lines?

- In order to mark parallel lines using a steel square, you will require a flat surface, a pencil or marking tool, and the steel square itself. Begin by placing the steel square on the flat surface, aligning one of its edges with the starting point of the line you wish to mark. Make sure to firmly hold the square against the surface to prevent any movement. Next, take the pencil or marking tool and position it against the inner edge of the square, ensuring that it is perpendicular to the square's edge. Adjust the marking tool's position until it aligns with the desired distance for the parallel line. Once the marking tool is properly positioned, carefully slide the square along the surface while keeping the marking tool against the inner edge of the square. This will generate a straight and parallel line that is equidistant from the original line. Repeat this procedure as necessary to mark multiple parallel lines using the same measurement. Always double-check that the square is correctly aligned and securely positioned against the surface before marking each line to guarantee accuracy and consistency.

- Q:How do you use a steel square to determine the slope of a sidewalk?

- To determine the slope of a sidewalk using a steel square, you would place one end of the square on the sidewalk and extend it towards the other end. By using a level or measuring the difference in height between the ends of the square, you can calculate the slope of the sidewalk.

- Q:What are the common applications of a steel square in masonry work?

- A steel square, also known as a framing square or carpenter's square, is a versatile tool that is commonly used in masonry work. It can be used for various tasks, including measuring, marking, and cutting materials. One of the common applications of a steel square in masonry work is for laying out and checking right angles. Masons often use the square to ensure that corners are perfectly square, which is crucial for achieving proper alignment and stability in masonry structures. They can place the square against the corner of a wall or foundation to check if it forms a 90-degree angle. If it doesn't, adjustments can be made to ensure the accuracy of the construction. Another common use of a steel square in masonry work is for making precise measurements. The tool has markings along its blade and tongue, allowing masons to measure various dimensions accurately. They can use it to measure the length and width of bricks or blocks, ensuring that they are of the desired size and shape. In addition, a steel square can be used for marking lines on masonry materials. Masons often need to mark cut lines or reference lines on bricks, blocks, or other materials before cutting or installing them. The square's straight edge can be aligned with the desired line, and a pencil or scribe can be used to mark the material accurately. Furthermore, a steel square can also be utilized as a cutting guide. Masons sometimes need to make straight cuts on bricks or blocks to fit them into specific spaces. The square can be used as a guide for a masonry saw or chisel, ensuring that the cut is straight and precise. Overall, the common applications of a steel square in masonry work include checking right angles, making measurements, marking lines, and serving as a cutting guide. Its versatility and accuracy make it an essential tool for masons, enabling them to achieve precise and high-quality masonry construction.

- Q:What are the different features to consider when buying a steel square?

- There are several important factors to take into account when purchasing a steel square. To begin with, the size of the square is of utmost importance. Steel squares are available in a variety of sizes, typically ranging from 6 inches to 24 inches. The size you opt for will depend on the scale of your projects and the level of precision you require. Furthermore, it is crucial to consider the material and build quality of the square. Look for a steel square that is constructed from high-quality steel, ensuring durability and the ability to withstand heavy use without succumbing to corrosion. Additionally, ensure that the square's construction is accurate, with straight edges and precise angles. The markings and measurements on the square are also vital aspects to consider. Seek out clear and easily legible markings that are permanently etched or stamped onto the square. These markings should include precise measurements in inches, centimeters, and degrees, enabling you to achieve accurate measurements and layout work. Another feature to bear in mind is the type of square. There are various types available, such as combination squares, framing squares, and try squares, each serving different purposes. Evaluate the specific tasks you will be utilizing the square for and choose the type that best caters to your needs. Additionally, take into consideration the weight and handle design of the square. A heavier square may offer enhanced stability, whereas a lighter one may be more comfortable to use for extended periods. The handle should be ergonomically designed and easy to grip, ensuring comfort and control during usage. Lastly, consider the brand and price of the steel square. It is generally advisable to opt for a reputable brand that has a proven history of producing high-quality tools. While price does not always guarantee quality, it is important to strike a balance between affordability and durability, ensuring that you obtain the most value for your money. In conclusion, when purchasing a steel square, take into account the size, material quality, markings, type, weight, handle design, brand, and price. By carefully evaluating these features, you can find a steel square that fulfills your specific requirements and provides accurate and dependable measurements for your projects.

- Q:How do you use a steel square to measure the width of a picture frame?

- To measure the width of a picture frame using a steel square, you would place one edge of the square against the inside of the frame, ensuring it is flush with the corner. Then, you can read the measurement off the scale on the square where the other edge aligns with the opposite side of the frame. This will give you an accurate measurement of the frame's width.

- Q:Can a steel square be used for checking the squareness of a wall frame?

- Yes, a steel square can be used for checking the squareness of a wall frame.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Structural Steel Square Bars S10C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords