Ceiling Grid Ceiling Light T Bar Suspended Ceiling Grid

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

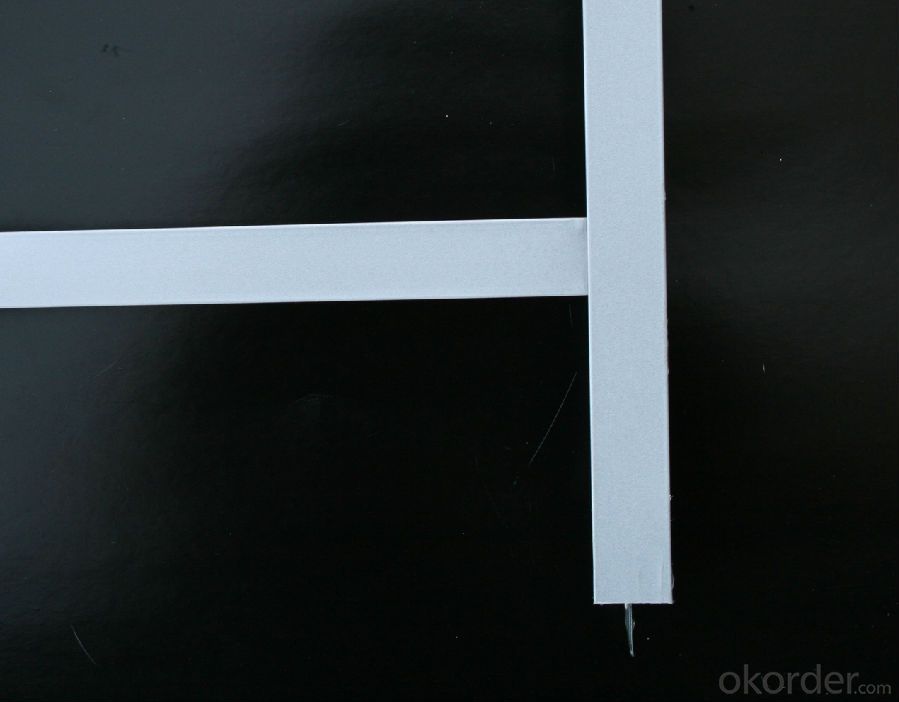

Grille ceiling system enables open ceiling plane constructions, offering a wide variety of cells and patterns for maximum freedom of design. Our panels are created with a proprietary manufacturing process that ensures clean lines and durability.

Product Applications:

1) Supermarket, marketplace

2) Service station, toll station

3) Underground, air port, bus station

4) School, office, meeting room

5) Hall, corridor and toilet

6) Sport center

7) Office, store, plaza

8) Hotel, restaurant, kitchen

9) Hospital

Product Advantages:

1)easily assemble, fast and convenient for installation/uninstallation.

2)light weight with high strength

3)more elegant in style and beauty, easy match to decoration

4)waterproof, shockproof, rustproof, fire resistance,cauterization-resistance,thermostatic

5)safe, firm and easy to match with all kinds of mineral fiber board, aluminum ceiling and gypsum board

Main Product Features:

The grid ceiling that has ventilating function and transparent construction; The outline of series is clear and natural and graceful, people like it very much! The hose carrier and vice-carrier adopt the fine aluminum alloy material. This grid ceiling can be used in the extensive places.

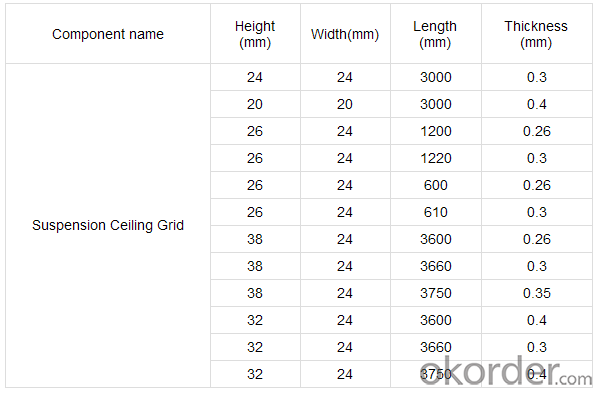

Product Specifications:

FAQ:

Q:How many the warranty years of your products?

A:15 years for indoor used,20 years for ourdoor used.

Q:Can you show me the installation instruction?

A:Yes,our engineering department is in charge of helping your installation.any question,you can let me know.

Images:

- Q:Has anyone ever designed a grid on their ceiling using say 1x3's stained or painted along sheetrock seams?

- depending on where your seams are I dout that it would work out right you would'nt have even no. of grids , unless it don't matter to you.

- Q:For example, T-keel ah, triangular keel ah, aluminum keel ah, etc., belong to the paint keel it

- You said the keel is used to do the ceiling, aluminum keel and paint keel is divided by material, aluminum surface oxide film protection, no paint, paint keel is in the ordinary metal keel surface to increase the paint protective layer, Paint keel, in the installation of anti-rust paint and a variety of colors when the finish; and T-keel triangle keel, is the ceiling keel section shape, different from the ceiling type, and some ceiling installation can be seen after the completion of Keel (T-type), and some ceiling installation can not see the keel (triangle).

- Q:Home decoration ceiling light steel keel best use what specifications

- Gypsum board to do their own home with 38 main bone .50 main bone can be hanging 50 pay bone with 38 main 0.8 1.0 1.2 / 50 main 0.8 1.0 1.2 thick / 50 paid 0.45 0.5 these can be used to use the best On the use of the national standard with the thickest of the general can be used with their own but with 38 main hanging gypsum board at least 1.0 thick with non-standard is not necessarily good with the national standard is not only in the thickness of the edge of the high only this is to see What are your own materials?

- Q:With gypsum board and light steel keel do partition wall, how much money a square meter?

- Even the material 60-70 yuan, wages 20 yuan / square meter

- Q:I'm putting suspended ceiling in my basement (using Armstrong tiles). Unfortunately, on one of the walls, the level of the ceiling has to be above the top level of the wall framing (it's a long story involving a structural beam, some heating vents and a window), so there are no studs behind the drywall where I need to attach the wall molding. Would molly bolts or something like that be able to support the weight of the suspended ceiling, should I try to cut some wood to fit and block in behind the drywall, or is there something else that I should do?

- Suspended Ceiling Wall Angle

- Q:Light steel keel is what material to do

- Materials and main equipment: 2.1.1 Light steel keel: the current wall works using light steel keel mainly support card series keel and through the series keel. Light steel keel main pieces along the top along the keel, strengthen the keel, vertical (horizontal) to the keel, cross the keel. Light steel keel accessories have support cards, Cato, angle care, connectors, fixtures, corners, pressure joints and so on. Light steel keel configuration should meet the design requirements. Keel should have product quality certificate. Keel appearance should be flat surface, angular straight, transition angle and trimming do not allow cracks and burrs, wheat noodles may not have serious pollution, corrosion and mechanical damage. 2.1.2 Fastening material: bolts, expansion bolts, galvanized tapping screws (2mm thick gypsum board with 25mm long screws, two 12mm thick gypsum board with 35mm long screws), wood screws, etc., should meet the design requirements. 2.l.3 Filling materials: glass wool, mineral wool board, rock wool board, according to the design requirements. 2.1.4 Gypsum board: Gypsum board should have product certification. Specifications should meet the requirements of the design drawings. General specifications are as follows: Length: according to the needs of the project to determine; Width: 1200mm, 900mm; Thickness: 9.5mm, 12mm, 15mm, 18mm, 25mm. Commonly used for 12mm. 2.1.5 Seam material: seam putty, fiberglass belt (cloth), 107 glue. 2.1.5.1 WKF joint putty: compressive strength> 3.0MPa, flexural strength> 1.5MPa, final setting time> 0.5h. 2.1.5.2 50mm Mesoporous glass fiber ribbon and fiberglass mesh: cloth weight> 80g / m2, mesh / in Breaking strength: 25mm × 100mm Cloth, warp> 300N Weft> 150N 2.1.6 Main machine: Plate saw, electric scissors, electric self-drilling, electric toothless saw, hand drill, nail gun, DC welding machine, scraper, line fall, by foot and so on.

- Q:Do you need a light steel keel or a wooden keel base? If there is, usually light steel keel or wood keel, if it is wood keel, need to brush what paint, fire paint to brush it?

- Need to angle iron (drilling) and stainless steel dry hanging accessories (corner bending. Expansion screws, etc.) AB glue. Not used wood keel for the grassroots.

- Q:anyone know how to put up something called ceiling max its like a drop ceiling that is a inch from ceiling?

- Great Link MM, but I don't see anything in the text that suggests the FREE space above all the grid work and tiles. Beyond that the text deals with a basement, and/or an area of exposed rafters. Normal drop ceiling requires a drop in the area of 8 inches minimum. I'd be doing Ceiling Max to cover damaged ceilings if I could get to within and inch or 2 of the old. The process, as explained is no different than normal grid install for a drop ceiling. I'll do more research however. The Q nudged an issue I have in a home, and I do drop ceilings with my Son often, commercially.

- Q:Light steel keel gypsum board ceiling length is greater than the number of need to stay expansion joints

- Light steel keel ceiling is generally divided into upper and no human type two. Master type for the 60 series of the main keel, not on the human type for the 50 series of the main keel. If there is no special requirements generally the main keel is 60 wide, the vice keel is 50 wide. According to the standard installation requirements of the spacing is not greater than 1200 * 1200, the first screw from the wall is not greater than 300.

- Q:While I won't get into the reasons why, I ended up drywalling my walls in a small sitting room in my basement before doing the ceiling. The walls have since been painted. What are my options for installing drywall in the ceiling and what types of roadblocks may I encounter when doing so?

- Wall studs in a new home are 16 on center. Studs in an older home were arbitrary. Since the studs in 1900 were a full 2 by 4 and made with Douglas Fir or Southern Yellow Pine which was more abundant and harder than the new whitewoods, in less expensive homes the spacing was as much as 24 apart. But in the more expensive homes the spacing could be as close as 12. It all depended on how much you were willing to spend. To find the studs in a wet plaster wall you need to buy the more expensive stud finder that penetrates deeper. Metal lathe can really complicate things too. I've had to go as far as driving a finish nail in every 1 till I ran across it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceiling Grid Ceiling Light T Bar Suspended Ceiling Grid

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords