ZYC series ZYC900B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

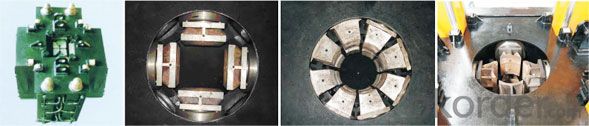

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 900 | suitable pile & specification(mm) | ¢400-800 | |

| Max. Piling speed(m/min) | 7.0 | Max. Crane lifting weight(t) | 20 | |

| Piling stroke(m) | 1.8 | Hanging pile length(m) | 15 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | 1650 | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | 3000 | |

| Max. Rise stroke(m) | 1.1 | Intensity of pressure(tf/m²) | 15.5/20.0 | |

| Max.rotation angle per time(°) | 8° | Weight composition | (t) Machine weight | 220±3 |

| Rated hydraulic system pressure(mpa) | 25(20) | Added water weight(t) | 50 | |

| Hydraulic Pump (Unit × Ml/Turn) | 3×125 + 1×80 | Counter weight(t) | 630 | |

| Motor power (Unit × kw) | 3×37 + 1×37 | Total weight(t) ≥ | 900 | |

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q:Rural housing foundation, piling machine generally can play how deep?

- 3, the use of XCMG power head, multi-stage shock absorption technology to ensure that the overall construction of more stable, power head key bar used in reverse and used to extend its service life.4 、 adopting the lock rod of the XCMG machine and the automatic lowering technique of the mast. The vertical precision of the pile hole is higher, and the construction is more convenient.5, the well-known brand "Yuchai engine," every little hour consumption 40-50 yuan.6, the use of wide, tube rice suitable for medium weathering below rock layer, sediment layer, backfill soil layer and other complex landforms.

- Q:Piling of percussive drilling

- 7, the drilling process control should be rigorous, but also do not have to worry about failure, a reasonable choice of treatment methods, generally can be solved, the common, foot blade perforation, hole collapse, partial hole, cross hole, drilling, drilling, drilling buried crane, well preventive measures are generally not in advance, very important duty responsibility. 8, the remaining holes, steel cage decentralization, concrete pouring, sealing and other are more conventional, do not write more. But the bottom of the hole, sediment, sediment, etc. must be recycled clean, otherwise it will be buried in the later works of greater risk. When the concrete is poured, the bottom concrete under the impact of residue inclusion in steel or bond caused by defects in the pile in concrete, on the upper structure of the load transfer to the bottom of the pile, the structure will definitely should produce uneven settlement for residue.

- Q:Does the diesel pile driver use electricity?

- The construction of their equipment. In addition to see how much power head in the face of tricyclic sticking case, two start if beyond the rated current it is easy to burn the motor, after all, a power head is not cheap, suggest you consider all hydraulic power head, the power head is three was a bit expensive, but in the face of the card when drilling, two times can start easily and smoothly, the impact of the power grid is very small. Moreover, the torque of the hydraulic power head is 2-3 times as much as that of the ordinary three ring power head. It is more suitable for complex formation than the traditional long spiral, and the construction efficiency is more efficient. Long spiral drill in the type piling machine is the use of a more extensive, and for starting current understanding, we can get better in the construction layout, so as to avoid the occurrence of the voltage is not enough at the time of construction.

- Q:120KW piling machine needs a lot of air?

- The general experience of 1 kW 2 amps, so we can use 250A open, because your motor power is relatively large, it is best to use a control box with a starter to safe operation.

- Q:What are the general safety hazards of temporary power and piling machines in the construction site?

- 3, the night construction should be safe and meet the lighting, lighting equipment and components should be consistent with the quality of the current national mandatory standards, not allowed to use insulation aging or damaged appliances and devices. In the event of a sudden power failure, the staff needs to evacuate the working place in time, it is necessary to install emergency lighting equipment with its own power supply.4, mobile power tools, hand-held power tools should be maintained before use, grounding, and the use of safety voltage. Electric tool load line should select type of weather resistant rubber sheathed copper cable and any joint. When using hand-held power tools, it is necessary to wear and wear protective clothing according to the rules.5, the use of self generating units, there should be special management.

- Q:What are the types of pile drivers? What are the characteristics of each?

- Pile foundation treatment has many ways, but according to the current market situation and the country's strict requirements for the foundation, many processes are not applicable, such as manual excavation, etc., the following are common and common process methods.According to backfill points: commonly used are lime soil pile, plain soil pile, cement pile, garbage pile and so on.According to the backfill compaction type: clamping rod hammer compaction, heavy hammer compaction

- Q:What is the working principle of a pile driver?

- Hammer piling machinePile hammer comprises a hammer head and a hammer base, with steam or compressed air as a driving force, a single action and double action two hammer hammer. Single acting piston or cylinder as the hammer to hammer, steam driven hammer up, then let the hammer seat along the guide rod fall and piling. Double acting steam hammer is increased as the plunger cylinder as the hammer to hammer, steam driven hammer up, then drive the downward impact hammer piling. The reciprocating speed is high and the frequency is high, so that the pile can vibrate when penetrating into the stratum, and the friction resistance can be reduced, and the pile driving effect is good. Differential two-way unequal force hammer, the hammer seat light weight, effective impact weight can be relatively stronger and better performance. The hammer into the exhaust valve reversing by manual control, can also be installed in the side with the hammer and hammer lifting flange lever automatic control, impact stroke two ways can adjust the hammer.

- Q:I want to learn construction piling machine, rely on it to earn money, the future to marry the daughter-in-law pension!

- Test piling permit can be trained by way of evidence, I have worked over these special operations personnel, piling a lot of points, see you want to learn that, 1. diesel hammer pile, 2. static pressure pile,.3 punching pile, 4. rotary pile,.5 drilling brick, and so on. All belong to special operations personnel, must obtain relevant documents to allow induction job, if there is an acquaintance of learning, soon get started.

- Q:How to use the pile driver?You're right. Contact 18961845125 before you know.

- 2. Adjust the position of the speed change gear of the pile driver according to the vibration force required by the construction personnel.3. Check whether the insulation of cables and wires is good. Check that the controller's contacts are good and that the bounds are correct.4. Check whether the voltage of the power supply meets the requirements.5, according to the daily maintenance project to each department lubrication, maintenance.Five, pile driver in the work safety precautions:1, when the piling machine work, there should be special command. The conductor and operator should check each other's signals before they work. Work closely together.2, at the start of the bell signal or other applications, notify the staff around to leave.3, hammer and pile cap, pile cap and column (or pile) plane to pad, a connecting bolt should be tightened, and should always check whether there is loose.4. The starting of the pile driver should be adjusted from low gear to high speed.

- Q:The grounding of piling machine. Pile machine, three-phase asynchronous motor one day to play 2 piles piling machine and control box are constantly moving, how to ground? And is not a machine box. A gate or a few feet to ground is the five core. In three, the rest of the root, the zero line and the PE are useless? Thank you, predecessors, great God under the guidance of? In this way, the master said that the reception will be over, installed a leak protection, is not installed, the leak insurance does not need to ground ah?

- The pile driver must be grounded reliably! Five core power cable, PE core wire may reach 16 square, in pile machine within 30 meters hit a 3 meter long galvanized angle (angle 50X5X3000), the head of a hole on the M10 (or M12) galvanized bolts, connecting 16 square BVR yellow green color line to the pile machine (repeat grounding), angle head (to prevent the hammer head welding deformation angle) a piece of iron, if you want to reuse (pull out in place again), can be connected with the hanging wire rope or a hook hole in angle steel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ZYC series ZYC900B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords