Sheet Pile Driver

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

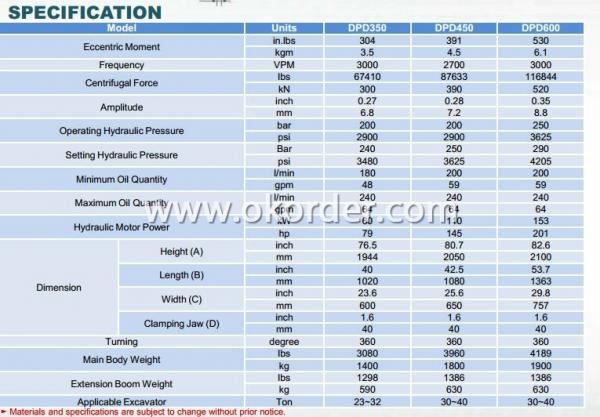

Detailed Product Description of Vibro Ripper, Hammer (Pile Driver)

- 360 degrees rotation of middle bracket

- Proven economic feasibility, mobility, safety

- Driving & Extraction sheet pile, tube, H-beam

- Most representative hydraulic vibro hammer

- Suitable equipment for construction working site

-Excellent performance and mechanisms without power pack.

-Proven workability: With the advantage of the excavator’s mobility, High performance operation at overpasses, under high voltage lines, on bridges and populated cities.

-Maximized the life of the equipment by using a special bearing designed for high frequency

-Best quality of Cushion elastomers are adopted in order to isolate vibration being transmitted to excavator.

-Easy installation using breaker hydraulic line of the excavator with electric cable device and operation control

-Mounting and dismounting can be easily done at all times

-The upper body allows 360 degree free rotation for easy operation and automatically anchors itself during operation

-Sheet pile, H beam and tube can be used by hooking up a wire on the main body of pile driver

-Double clamping devices can be fitted for pipe driving and extracting (Option)

- Q:Can you drive an excavator? Can you learn it quickly?

- Learn to dig, you can, the teacher, father, a month's wages are more than 10000!

- Q:How many types of piles are there in the site? What procedures are usually used for piling? Such as eyes open what kind of..

- (1) driven pile;The driven pile is to pile the pile into the foundation soil by the power impact of the machine. The ancient stakes were artificially driven, while modern driven piles employ a variety of specialized piling machines, such as diesel hammers, pile drivers, etc..In order to reduce the vibration, especially to overcome the larger pile resistance, a shallow hole or a small pile hole is drilled at the foundation pile position, and then the pile body is inserted into the pile. This often happens when piling meets the local hard soil or the lens is decent and difficult to pass through. The pre drilling method is convenient for the construction, but it also reduces the effect of the pile compacting and has a certain loss of the bearing capacity of the pile, which should be estimated in the design of pile foundation.(2) press in pileThe pressed pile is pressed by a special pile driver to push the prefabricated pile into the ground by static force. The method of pressing construction there is almost no pile that problems such as vibration and noise, but the pile capacity is less than the driving method, it is suitable for the requirements on bearing capacity of the pile is not very high, such as the underpinning both building foundation.

- Q:There are also some related costs. Originally wanted to buy a pile driver, the budget of 100-200. I hope my friends will give me some advice.. Thank you

- Depends on what project you do, if there is no noise requirements, diesel hammer piling machine is better, a price at about 500000, back to Ben faster. The hydrostatic press is a bit heavy.

- Q:How to safely operate a pile driver?

- (10) power cable static pile pressing machine must overhead, electric box and motor ground zero protection line electric shock protector is firm and reliable, sensitive and effective action, not in high voltage wires under the pressure of pile, pile machine must be mobile and high-pressure line safety distance is not less than 6m.(11) before operation, should check the hydraulic system connection parts are reliable, no-load operation, check whether there is oil leakage, pressure gauge, safety valve is normal, confirm safe and reliable, before you can work.(12) during the piling operation, a warning area should be set up to prevent pedestrians from passing or standing.(13) when the pile machine fails, it should be power off, stop, report the overhaul of the machine repair group, and shall not check and repair without permission.(14) in case of heavy rain, heavy fog, or six or higher winds, the piling operation shall be stopped immediately, and the pile driving machine shall be reinforced.

- Q:How to realize the remote control of pile driver (machine)?

- Hello,Piling machine (Mechanical) are generally used for CAN-bus communication, similar to the traditional automobile communication scheme is using twisted pair as a communication medium,

- Q:Does the mud come up with the shovel? Can you tamper with a stone? 1.2 traction? How many meters per hour can the ramming mud fall? And the price of the equipment! It's better to have a talk with that big brother! Thank you on your knees

- this not move so we will look at the geological prospecting will not find a understand Someone helps you see if you're going to lose it.)

- Q:What kind of industry can use a pile driver?

- Pile driver: economic development, led to the rapid development of the industry, especially in recent years, urban and rural areas and highways, railways, power stations and other construction to accelerate the development of pile machinery. Such as our factory production of this kind of pile machinery, more subdivision, more widely used.?Piling machine basically can be divided into hydraulic piling machine, foundation piling machine, piling machine, photovoltaic power plant hammer piling machine, hammer piling machine and four kinds of diesel hammer piling machine. Each kind of work principle is not the same.

- Q:What safety measures should be taken when assembling a pile driver?

- This thing must have the safety, rules and regulations, but the key is to have this awareness, the following for your reference, I hope to help you.1 、 safety management system of mechanical equipmentLeaders at all levels should strengthen the safety work of mechanical equipment often carry out safety production leadership, ideological education and safety education of workers, the leaders at all levels included in the safety target management schedule, prohibited illegal command, illegal operation, violation of labor discipline and reckless ignorance and other unsafe behavior, leaders should regularly organize relevant personnel go to the scene, the supervision and inspection of mechanical safety work, to correct the problem, promptly eliminate hidden dangers, make the mechanical equipment to achieve safety, high quality, high efficiency and low energy consumption operation, the long-term safe production and take measures to eliminate hidden dangers and prevent accidents of personnel should be commended and rewarded.Urge all kinds of machinery and equipment operators to seriously study safety technical operation procedures, and those who violate safety technical procedures must be stopped, and can be continued before improvement. After the arrival of the new model, there is no safety technical operating procedures, it must be in accordance with the requirements of the instructions, first formulate safety operation procedures and precautions before they can be put into use.

- Q:What's the model of a portable anti flood pile driver? What is the depth of the pile?

- Shape size * height * width 450*350*450mm3) work parameters:Operation object: River, Hutang embankment (homogeneous soil)Pile diameter: 60 - 120mmLength: less than or equal to 3000mmPile driving speed: 500-1000mm/minIf you don't know, you can ask me again

- Q:Bridge pile driver is a stone below, how to do?

- What's your machine, please? If your machine is an impact drill, I suggest you use the hollow hammer. The ventilation is fast, the cross drill is easy to break, the side is slow, and several drilling rigs have their respective numbers. Next time they are talking to you

1. Manufacturer Overview |

|

|---|---|

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sheet Pile Driver

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords