ZYC series ZYC500B-B Multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

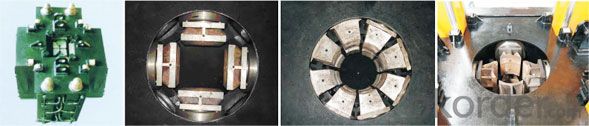

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 500 | suitable pile & specification(mm) | ¢300-600 | |

| Max. Piling speed(m/min) | 6.5 | Max. Crane lifting weight(t) | 16 | |

| Piling stroke(m) | 1.8 | Hanging pile length(m) | 15 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | 1380 | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | 2800 | |

| Max. Rise stroke(m) | 1.1 | Intensity of pressure(tf/m²) | 12.5/15.0 | |

| Max.rotation angle per time(°) | 11° | Weight composition | (t) Machine weight | 158±2 |

| Rated hydraulic system pressure(mpa) | 23(20) | Added water weight(t) | 36 | |

| Hydraulic Pump (Unit × Ml/Turn) | 3×80 + 1×80 | Counter weight(t) | 306 | |

| Motor power (Unit × kw) | 3×37 + 1×30 | Total weight(t) ≥ | 500 | |

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

- Q:The difference between diesel pile driver and impact drilling machine

- A diesel pile driver: like a hammer hitting a nail, it is hit by a hammer.Percussive drill: like percussive drilling, it is drilled out during impact.

- Q:What are the prospects for a small pile driver and a foundation pile driver? Will it make money?

- like Hunan Huilong piling machine is generally divided into: Machine lock rod rotary drilling rig, caterpillar rotary drilling rig, crawler wheel screw drilling machine, rotary drilling rig.

- Q:In what type of terrain can the survival machine be used to strike minerals?

- Any terrain. As long as you dare to go down

- Q:Working principle of pile driver

- Pile driver is a kind of piling machine that uses the impact force to push the pile into the formation.It consists of a pile hammer, a pile stand and auxiliary equipment.

- Q:In the construction project, the pile driver can not be reached. What should the supervisor do?

- Stop. Check cause. Geological prospecting and prospecting

- Q:My family is in the countryside, and now more than 100 meters behind the house in the pile is the kind of shock, our house is built in 99 years, has been very good. Since the piling, I have been shaking the door, the construction party every day for more than 8 hours, has been more than 10 days, and now I have a lot of cracks in the floor. What's the influence of our family, please? Are there any rules for investigating what should be done before piling?

- The best co-ordination, not to consult the Construction Planning Bureau

- Q:What are the characteristics of hydraulic static piling compared with traditional pile driver?

- The pile is pressed by its own weight. Besides the weight of the pile, the weight of the pile should be installed with a total weight of more than 600 tons to the thousand tons.There is a large power hydraulic pump station with maximum power of more than 300 kW at run time.The pressure prefabricated pipe pile is clamped by hydraulic cylinder and pressed down by segment. The noise and vibration are smaller, and the bearing capacity can be known.Pile with hook.

- Q:Precast pile, artificial dig hole pile, sinking pipe filling pile, spiral drilling pouring pile and powder spraying pile.

- Or buy cost-effective, piling machine is not too expensive, you sit down two projects can basically return to this, recommended Zhengzhou, is a large pile machinery company, the efficiency is much higher than the others.

- Q:Why does the pile driver smoke? What's the structure like? Where does the oil go?

- Pile hammer into hydraulic pile hammer (beginning D number) and diesel hammer, hydraulic hammer by the power station power supply, do not smoke, diesel hammer depends on the piston down after compression ignition diesel power supply, diesel combustion smoke.

- Q:Why should the pile foundation be excavated after the pile driving?

- The construction of the pile foundation shall be done by piling and excavating the earth as follows:The first excavation, construction and basement, excavation depth from plus or minus 00 may have a depth of 4 meters, 4 meters below the ground, the general quality is difficult to ensure, at this time it is difficult to support the ground operation requirements, especially when the mechanical operation. It is difficult to estimate the change of groundwater, the coming of rainy season, and the cost and time of these external factors will be played directly as compared with the original ground.In general, the plant should dig the earth before the foundation pit is supported, and then the pile will be made. Concrete car can be outside the pit, by pouring over to the bottom of the pit. Of course, if the surface of the excavation is silt layer / or below the shallow water level is special. If the deep foundation pit is used, it is better to dig the soil first and then make the pile, so the concrete pouring is not a problem.The soft soil area must have been dug before and after, for a very simple reason. Soft soil generally has a hard surface layer, so that it is conducive to the movement and construction of pile foundation. If there is no hard surface on the surface, then make the cast-in-place bottom and then pile the pile. In addition, the foundation pit supporting in the soft soil area is a relatively difficult and easy to occur accident process, and the construction grouting pile will certainly affect the excavation and support of basement, and the mud pool will not know where to put it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ZYC series ZYC500B-B Multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords