Vibro Ripper (DBL Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Sets watt

- Supply Capability:

- 1000 Sets per Month watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Vibro Ripper (DBL Series)

-Innovative, Reliable Original Vibro Ripper in The World!

-Powerful digging force by special vibration structure

VIBRO RIPPER

(DBL Series )

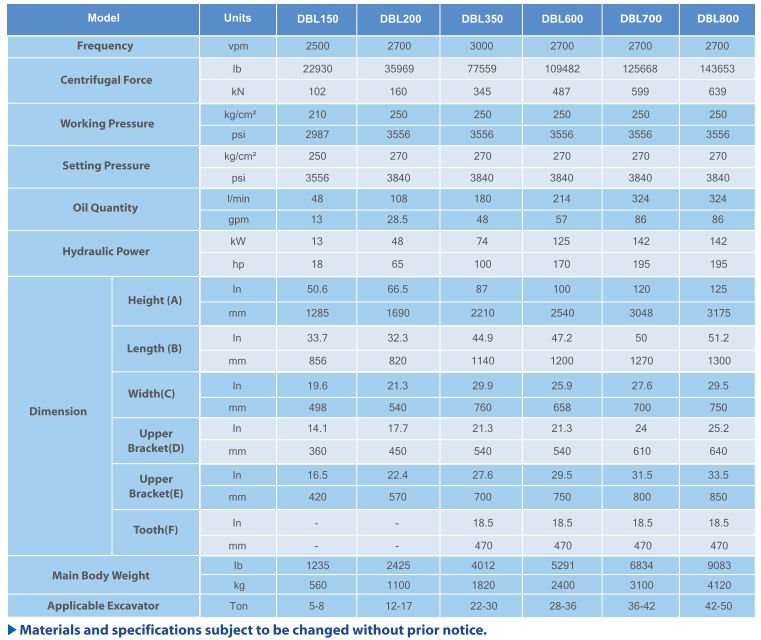

DBL150, DBL200,DBL350,DBL600,DBL700,DBL800

Patent Status

-World Patent PCT No.KR2007/004427

-U.S.A Patent No.12/673,152

-European Patent No.07 808 218 7

-Korea Patent No.10-0755017, No.10-0878296

-Innovative, Reliable Original Vibro Ripper in The World!

-Powerful digging force by special vibration structure

-Noiseless & Eco-friendly Vibrating Ripper

-No scattering of debris during digging operation

-Higher Production & efficiency

-Noiseless and eco friendly equipment (approx. 52~65dB lower than an equivalent hammer)

-Up to double and three times of productivity compared with an equivalent hydraulic hammer

-Easy installation to excavator with breaker hydraulic lines

-Utilizes 2,700rpm of high frequency vibration

-Patented heavy duty of elastomers(cushion elastomer) insolates the excavator from vibration shock

-Mounting and dismounting with 5~40 ton excavator boom at any time easily

-Innovatively designed tooth & pin have improved the durability

-Powerful breaking performance by high frequency motor

-Innovative technology, more powerful vibration and less noise level than ever

-Increased life time for the equipment by applying the oil rotation power system

-Developed with a patented high frequency vibration technology world first, which makes it in 80% of job site more productive than any rock breaker.

-Application area : it can work in tunnels, road extension section, public grievance, downtown, foundations, muddy, wet zone and under water places

Technical Specification of Vibro Ripper (DBL Series)

- Q:Is the spiral pile driver still being dug? Is it easy to operate? How many people do you need?

- Tengzhou Five Dragon pile driver is very good, without artificial shovel, 360 degrees rotation, six minutes can hit ten meters, diameter two meters!

- Q:How many types of piles are there in the site? What procedures are usually used for piling? Such as eyes open what kind of..

- Precast pile, artificial dig hole pile, sinking pipe filling pile, spiral drilling pouring pile and powder spraying pile.

- Q:How many piles can a small pile driver hit in a day?

- You can Baidu a little dragon, small pile driver consulting

- Q:What are the main types of pile drivers?

- And fuel injection, explosion, shock, ventilation and other work. The work is to rely on diesel hammer compression ignition diesel to start, it is necessary to ensure the cylinder seal The gas reaches a certain compression ratio, sometimes piling in soft soil layer is often because the reaction is too small, the amount of compression is not sufficient to ignite the initiation, you need to use multiple hook lift hammer decoupling impact, to start. The hammer seat diesel hammer with a fuel injection pump, fuel tank, cooling water tank and the pile cap. Play between the piston and the cylinder with elastic piston ring seal.x0d four hydraulic hammer x0d diesel oil to start with, the pressure into motivation, according to different soil hydraulic impact force to achieve the adjustment, the appropriate piling, is a new type of piling machine. Small and medium sized hydraulic piling machine, piling commonly used in the highway guardrail, highway guardrail construction. Similar piling equipment: hydraulic piling machine, highway guardrail, piling machine, piling machine road drill.

- Q:How much can a pile driver make in a year?

- Hello Can contact Huilong spiral drill, rotary drilling is burning diesel, the average is 40 or so, to see what much of the diesel engine, what brand of Oh ~ what needs, you can consult a wylong machinery in Hunan!

- Q:I have two pile drivers, followed by engineering piling, what qualifications do you need?

- Hang on it, for qualification trouble. You can contact me if you need to buy piling equipment.

- Q:Precast pile, artificial dig hole pile, sinking pipe filling pile, spiral drilling pouring pile and powder spraying pile.

- Or buy cost-effective, piling machine is not too expensive, you sit down two projects can basically return to this, recommended Zhengzhou, is a large pile machinery company, the efficiency is much higher than the others.

- Q:What's the difference between a amd bulldozer and a pile driver?

- AMD is the APU architecture, you can understand that the bulldozers for the powerful pipeline, row slowly push forward, side by side work, quad core four line outThe piling machine is on both sides of the 4 Alice type, 2 core graphics processor are respectively divided into 2 streams,

- Q:such as bulldozers, pile drivers, cranes and cement mixers?

- Promote。 As for Chinese chopsticks, fork to foreigners, the Xu

- Q:Why should the pile foundation be excavated after the pile driving?

- It is convenient to measure and locate the center of the pile, and also facilitate the approach of the piling machine

1. Manufacturer Overview |

|

|---|---|

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vibro Ripper (DBL Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Sets watt

- Supply Capability:

- 1000 Sets per Month watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords