Pile Driver (DPD Tilting Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Pile Driver (DPD Tilting Clamp Type Series)

-360 degrees free rotation & 90 degrees tilting rotation of jaw clamp

-Simple replacement tooth of pile clamp

SHEET PILE DRIVER (TILTING TYPE)

DPD Tilting Series

(PATENT NO.10-0851430)

- 30% better efficiency of construction working site

- 90 degrees Tilting devices

- Easy & Accurate control tilting operation system

- Tested safety through double device

- This leads to greater customer satisfaction!

- The tilting sheet pile driver can be operated alone ; No necessary assistant worker

- As it tilts up to 90 degree, the operation with sheet pile, H beam, tube, pipe, and steel can easily be controlled without the help of another worker. The cost of one worker can be saved

- Maximizes operational performance with its much more enhanced functions

- Best in 35 ton class for impulse and clamping power

- Dramatically reduces costs of transport and assistant worker

- Highly improved sheet piling operation method

- Extended service life using a special bearing designed for high frequency vibration

- Heavy duty Special elastomers (Patent) isolate vibration protecting the excavator from damage

- Making the best use of the excavator, operation in a narrow space is possible

- Easy installation using breaker hydraulic lines of the excavator and electric one control cable device

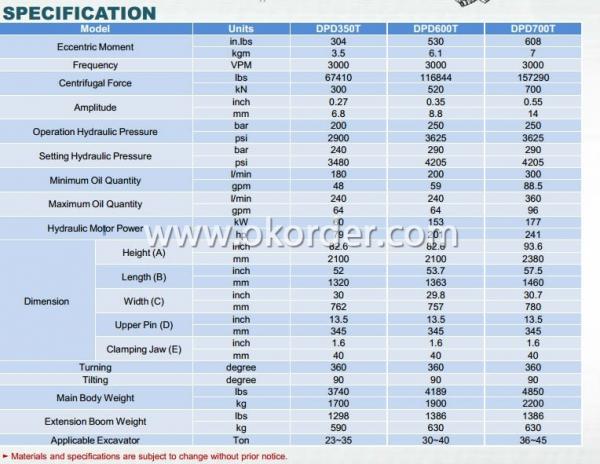

Specification of Pile Driver (DPD Tilting Clamp Type Series)

- Q:A pile driver 1 team can play many 12mI36b steel sheet pile

- According to the geological conditions are different450 pile driverThe number of 9m Larson steel sheet piles is about 100 a day300 times the pile driverTrough sheet steel piles 9m in 200-300 days at a timeGive you a reference: 80 tonsThis is my construction data, I do not know, quasi accurate, you can refer to the next slightly!

- Q:How many piles can a small pile driver hit in a day?

- See you hit the big pile, 600 5 meters deep as long as 5 minutes, 1.2 meters high 5 meters deep as long as 20 minutes, without concrete words, you can calculate according to the time

- Q:If so, ask what it works forThe pile hammers I've seen before all have a steam hammer, and this one doesn't know how it works.

- A static pile driver that presses the cylinder into the ground with the machine! Foundation reinforcement!

- Q:In the construction project, the pile driver can not be reached. What should the supervisor do?

- Hold supervision meeting;Analysis reason;Take out the treatment plan.

- Q:Buying a pile driver doesn't know how to make a profit Has anyone done that yet?

- Generally speaking, piling this industry is better to make money, but it will be more difficult, after all, is heavy physical labor. If you can do it for a long time, you can make money basically. But also can not guarantee, mainly depends on how your construction site, and whether you can answer the live, the most important thing is to have a good pile driver, long service life, mechanical problems.

- Q:Handan steel sheet piling machine a number of how much money

- According to the quality450 pile driverHit 9m Larson steel sheet pile about 100300 pile driverTrough steel sheet pile 9m 200-300Reference data: 80 tonsI know the construction data, quasi quasi reference

- Q:Invite friends together to buy a long spiral step of 30 meters of the pile driver, told me as long as the project profits are objective, you can package to 200W/, would like to ask the experts familiar with the bank bosses according to your local market if the annual package is how much money, how much is the monthly package, or by how many meters.. Thank you。。 Thank you

- 1, Shandong small 360 degree rotation of the kind of Shandong strong machinery factory, sold in about 6-8;2, long spiral pile driver is a long spiral drilling machine another name, later called long spiral drilling machine.

- Q:AMD FX 8350 eight core CPU AM3+ piling machine and tin box what is the difference between the master pointing

- But I don't think AMD's best CPU is comfortable with 3 generations of I5. Convert video files, 8 kernel conversions, 5 loads, and 5 88%-93% loads. But the AMD platform, CPU, is a good game to play.But you do not tangle FX8350 and CPU tin boxes are the same, only the original box packing box fan is different these can ignore the FX8350 are on separate heat.

- Q:What is an impact pile driver?

- You mean the kind of pile driver that used to use high explosive diesel engines to produce impact?The principle is like using the percussion hammer nails, using a hammer impact in the nail head will generate the nail.It's very seldom used now.

- Q:Which is better, wheel driven pile driver or caterpillar rotary drilling rig? What's the difference between workmanship?

- A wheel on a walking crawler. Matlock crawler can, more than 10 cm of the silt to climb.

1. Manufacturer Overview |

|

|---|---|

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pile Driver (DPD Tilting Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords