Grinding Glass Beads

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Kilograms kg

- Supply Capability:

- 500 Tons per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

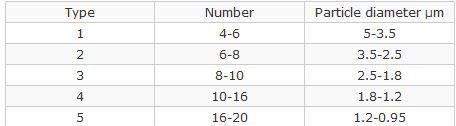

Grinding Glass Beads

strong hardness

new glasses for material

Round ratio above 85%

ISO, CE

Grinding Glass Beads

III. Hardness

HV, Loading 100g, residence time: 12s

the average of five point: 5270Mpa

standard

code(HV): ≥ 5000Mpa

IV. percentage of damage

1. test condition

(1)shot peening Target:Thickness:1.2mm (steel plate)

(2)air pressure of the nozzle:0.3Mpa

(3)the space between the nozzle and the Target: 200mm

(4) time of shot peening:5min

(5)the diameter of the glass beads: 250 microns

(6)Gross Weight of the tested glass beads: 1020g

(7) the weight of the damaged

glass beads after shot peening: 1.02g

2.percentage of damage of the test : 0.1%

V. Application

They are mainly used for the disperser, grinding media of industries, such as coloring, paint, ink, coatings, resins, chemical engineering, with the advantages of smooth surface, even size, high hardness, good chemical stability. Thanks to the characteristics of heat-resistant, wearable, compression strength, the filling-type bead could be used to improve glass fibre reinforced plastic, rubber, and so on.

- Q:How many hours will it take for the 200 piles and the 1 pile drivers?

- Because there is a piling process: measurement line - out pile connection - send pile inspection -- moving pile pile machine in place -- the original check -- prefabricated pile precast pile lifting pile stabilizing pile -- -- --.It depends on what kind of pile, the diameter of the pile, the geological condition, the construction site, the construction organization and so on.Taking prestressed pipe pile of 18M as an exampleAbout 20 per day, about 10 hours / day, and that is exactly every half an hour. This refers to the "stability, pressure, connection and delivery" critical progress, because other schedules can be arranged in parallel. While not completely parallel arrangement, the efficiency drops by half, that is, it takes 1 hours to hit a pile.So it takes a lot of skilled workers to finish the job faster.

- Q:What are the types of construction piling? What are the characteristics?

- The main load of single pile is the cast-in-place concrete pile with rotary drilling holes.The above is the classification of the process, and how many layers are suitable for the construction. This is not clearly defined. It mainly depends on the geological conditions and the superstructure. Who can tell you clearly that it is all Mongolia?.According to the above features you can see, generally divided into two categories, diesel hammer hole, drill hole, Luoyang shovel into the hole is used more, low cost, suitable for Northwest collapsible loess, the pile can eliminate the collapsibility of loess geology, increase the original basis composite bearing capacity. The pipe pile should be chosen according to the address condition, and the construction cost is high. According to the geological difference, sometimes the diesel hammer or drilling machine is needed to carry out the pre boring operation. Rotary drilling drill across the country for a variety of industries (work, the DAB, railways, highways, bridges, etc.), is the best way to operate a single pile.Specific choices are based on geological conditions and superstructure, and geological moisture content is also a key. I am engaged in the foundation construction, any questions contact at any time. Of course, there is a better engineering, ha ha, all kinds of machinery are available, are free equipment, reasonable price appropriate.

- Q:Why are pile driving boring often deflected?

- Because of the address, it's better to fix it and then fix it on the steel plate pile.

- Q:In the construction project, the pile driver can not be reached. What should the supervisor do?

- Stop piling. What's that pile of yours? Analyze the reason and see how much the pile is under pressure

- Q:I heard that the operation of the pile driver can make about ten thousand a month, is it possible? It sounds a bit dodgy. Who knows about this job? Please tell me how much you can make it for a month

- Generally similar, but if the site is more, then more than this money

- Q:what kind of VLV cable is needed, how to determine, after the cable from the low-voltage distribution box out, 460m arrived distribution of electricity 100It's best to explain how to calculate, how to determine the current, and the specifications of the cable, thank you very much!630 of the box changed to the distribution box for the cable, 240 of the cable is single core, or 3*240 cable. What kind of cable can be specific about it? Underground directly buried, directly to a cable model, aluminum core cable

- Current of pile driver 5*75=375KW/0.8=468.75KW/380/1.732=712AThe ampacity of the cable is 240 square meters, about 390ASo we need two 240 square parallel.

- Q:A screw driver pile diameter 400mm depth of not less than 12 meters, 24 hours a day non-stop, how much can be hit?

- A screw driver pile diameter 400mm depth of not less than 12 meters, 24 hours a day non-stop, how much can be hit?

- Q:Excavators, pile drivers, how to operate? The master knows,

- Simple, first stop the car, push the right handle forward (big arm down), push the left hand lever (small arm out), handle the right (release bucket), do the above three actions at the same time until the bucket touches the ground. Then, the left handle back down and right arm handle down the left arm when receiving bucket, bucket is full. Then the big arm, left or right rotation and small rotating arm bucket on the line! Got it?! You can also question me!

- Q:Which brand is good for a pile driver / pile driver?

- Pile driver has multiple types of wheeled and tracked, allowing users to have more choices, but in terms of pricing is reasonable, domestic brands in the relatively high cost of sales in the top brands, many brands.

- Q:Is there an operation certificate for percussive drill driver?

- at the top of the main frame is fixedly connected with the pulley first, the lower part is provided with a steering pulley, the pulley head and a steering pulley connected by wire rope transmission; one end of the wire rope is fixedly connected with the hammer, the other end is connected to a winch Part; the manipulation of PLC electric control box, automatic operation mechanism began to work, you can control the opening and closing part of piling winch clutch, the automatic impact drill piling machine has the advantages of simple structure, low cost, convenient operation, reliable performance.

1. Manufacturer Overview |

|

|---|---|

| Location | Liaoning, China (Mainland) |

| Year Established | 2000 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe |

| Company Certifications | ISO:9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Grinding Glass Beads

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Kilograms kg

- Supply Capability:

- 500 Tons per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords