Pile Driver (DPD Fixed Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Pile Driver (DPD Fixed Clamp Type Series)

-Proven economic feasibility, mobility, safety

-360 degrees rotation devices of middle brackets

SHEET PILE DRIVER (GENERAL TYPE)

DPD Fixed Clamp Series - DPD350

- 360 degrees rotation of middle bracket

- Proven economic feasibility, mobility, safety

- Driving & Extraction sheet pile, tube, H-beam

- Most representative hydraulic vibro hammer

- Suitable equipment for construction working site

Excellent performance and mechanisms without power pack.

Proven workability: With the advantage of the excavator’s mobility, High performance operation at overpasses, under high voltage lines, on bridges and populated cities.

-Maximized the life of the equipment by using a special bearing designed for high frequency

-Best quality of Cushion elastomers are adopted in order to isolate vibration being transmitted to excavator.

-Easy installation using breaker hydraulic line of the excavator with electric cable device and operation control

-Mounting and dismounting can be easily done at all times

-The upper body allows 360 degree free rotation for easy operation and automatically anchors itself during operation

-Sheet pile, H beam and tube can be used by hooking up a wire on the main body of pile driver

-Double clamping devices can be fitted for pipe driving and extracting (Option)

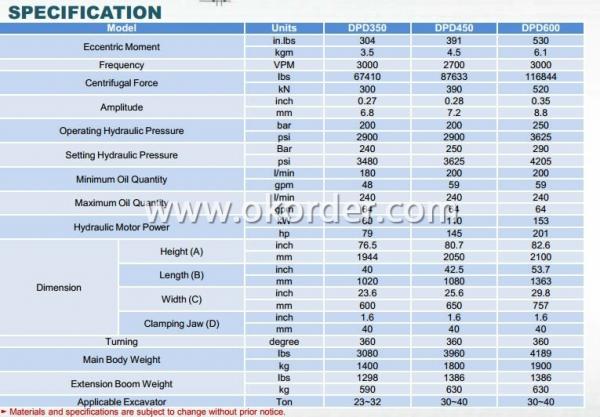

Specification of Pile Driver (DPD Fixed Clamp Type Series)

- Q:A pile driver 1 team can play many 12mI36b steel sheet pile

- According to the geological conditions are different450 pile driverThe number of 9m Larson steel sheet piles is about 100 a day300 times the pile driver

- Q:What is the classification of piling equipment? A little more detail, please

- The vibration pile machine, static uplift pile machine, pile hammer machine, static pile machine, deep mixing pile machine, jet pile base and so on, the general pile hammer machine for suburban noise, smoke pollution, static pressure pile machine is used in the city, small noise will probably ~ ~

- Q:How much power does piling work at a construction site?

- You see what device ah, various devices are not the same, but to remind you that the cable in piling time as far as possible with a point, otherwise it is easy to jump, because during each equipment operation at the same time, need a larger coefficient.

- Q:There are also some related costs. Originally wanted to buy a pile driver, the budget of 100-200. I hope my friends will give me some advice.. Thank you

- Depends on what project you do, if there is no noise requirements, diesel hammer piling machine is better, a price at about 500000, back to Ben faster. The hydrostatic press is a bit heavy.

- Q:What are the types of pile drivers?

- According to the structural form of diesel hammer rod and cylinder type separation.Hydraulic hammer pile driverThe utility model is a diesel belt starting, with the hydraulic pressure as the power, and can adjust the hydraulic pressure according to the different stratum soil, so as to achieve the appropriate impact force for piling, and is a new type of pile driver. Small and medium-sized hydraulic pile driver, commonly used in highway guardrail piling, highway guardrail construction.Screw pile driverSpiral pile driver (Spiral hammers) is a power driven drill head drill bit into the underground drilling machine drilling equipment. The spiral pile driver can be divided into two parts: the pile foundation and the drilling part.

- Q:How much is a steel sheet pile driver?

- Where do you use it?! How long will it take? What kind of pile driver?

- Q:Buying a pile driver doesn't know how to make a profit Has anyone done that yet?

- Because, after all, the pile driver is not only a few years, the choice of good quality in the early may not be cost-effective, but after taking into account, or suggest that you buy a little bit of the machine. After all, if the driver problem that you every two or three days, the work is not good for.

- Q:I have a pile machine construction record card, but Supervision said or not, please master pointing.

- If there is any nonconformity, the rectification shall be completed and checked by the supervision.

- Q:What are the preparations for the piling site?

- 1, the pile position determination: according to the project provided by the construction unit and the pile axis location map of pile location, pile location must be accurate, and in the pile position by a soldering iron drilling, hole depth is 15~20cm, filled with lime, prevent in the process of driving the wrong pile.2. Pile up(1) pile stacking shall be determined by pile driving route and pile driving sequence(2) the site shall be level and level with three passes and one leveling. Remove obstacles in the ground, underground and air in the range of the moving of the pile driver. The wooden posts and the pile rings shall be of the same position, except for the contact between the pile and the pile, and nothing else shall be in contact with the pile so as to prevent cracks in the pile.(3) the strength of reinforced concrete precast piles must be up to 100% before they can be transported and piled3, the selection of pile machineAccording to the design of single pile bearing capacity and pile length, this project intends to use hammer weight 2.5t track type diesel pile driver.

- Q:How much voltage does a tower crane need, and how much voltage does the 160A meter equal?

- The site of the hydraulic piling machine and crane are in need of three-phase power supply of 380/220V, the general piling machine power is about 40KW, the crane power is about 70KW, so probably need 110~130KW power, three-phase 160A meter can take 105KW, general electric meter overload ability than the wall, with 1 sets of hydraulic piling machines and 1 sets of tower crane very reluctantly can.

1. Manufacturer Overview |

|

|---|---|

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pile Driver (DPD Fixed Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords