Korean Excavator Vibro Attachment

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Sets set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Korean Excavator Vibro Attachment

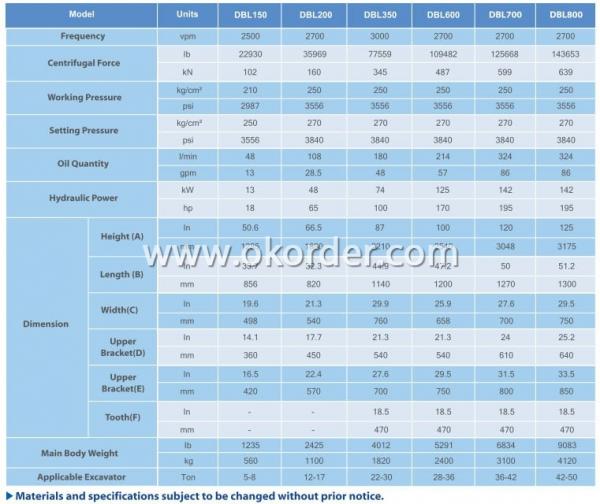

(DBL Series ) DBL150, DBL200,DBL350,DBL600,DBL700,DBL800

Patent Status

-World Patent PCT No.KR2007/004427

-U.S.A Patent No.12/673,152

-European Patent No.07 808 218 7

-Korea Patent No.10-0755017, No.10-0878296

-Innovative, Reliable Original Vibro Ripper in The World!

-Powerful digging force by special vibration structure

-Noiseless & Eco-friendly Vibrating Ripper

-No scattering of debris during digging operation

-Higher Production & efficiency

-Noiseless and eco friendly equipment (approx. 52~65dB lower than an equivalent hammer)

-Up to double and three times of productivity compared with an equivalent hydraulic hammer

-Easy installation to excavator with breaker hydraulic lines

-Utilizes 2,700rpm of high frequency vibration

-Patented heavy duty of elastomers(cushion elastomer) insolates the excavator from vibration shock

-Mounting and dismounting with 5~40 ton excavator boom at any time easily

-Innovatively designed tooth & pin have improved the durability

-Powerful breaking performance by high frequency motor

-Innovative technology, more powerful vibration and less noise level than ever

-Increased life time for the equipment by applying the oil rotation power system

-Developed with a patented high frequency vibration technology world first, which makes it in 80% of job site more productive than any rock breaker.

-Application area : it can work in tunnels, road extension section, public grievance, downtown, foundations, muddy, wet zone and under water places

Technical Specification of Korean Excavator Vibro Attachment

- Q:How much are the pile and Larson piles of a pile driver?

- Chasing the answerI mainly do Larson steel sheet pile products. Domestic 5000 or so, Japan imports 6450.

- Q:What should I pay attention to when purchasing a hydraulic pile driver?

- Upstairs is right, but you can ask the salesman, blue ocean machinery company's service is very thoughtful, you can see

- Q:Do you have a teacher with you?. I am 32 years old this year. I really want to learn this kind of machine

- I just open this, there is a certain risk, high wages, the site can not enter the work, it does not enter

- Q:now to pull out, how can pull out? FiveThe machine can not be used, how to take out in a simple way! Now, how many tons of jacks do I need if I use a jack?

- Is it possible to use a vibratory hammer, or a hydraulic high frequency vibrator?.

- Q:Under the high voltage line, within two meters on both sides, no pile driver shall be installed

- No piling machine shall be installed within 10m on both sides of high tension line.

- Q:What's the difference between a pile driver and a boring pile driver?

- Piling machine generally refers to prefabricated prefabricated pile hoisting, with heavy hammer into the underground or static pressure into the underground machinery. The bored pile machine is the first hole, the next steel cage, and then pouring concrete machinery.The difference is that the pile in the construction of the pile driver is prefabricated.The bored pile machine is a cast-in-place pile on the spot

- Q:Can the piling machine be built at night?

- In principle, it is not allowed to work at night, unless it does not affect anyone's life, study and work, and does not constitute noise pollution.

- Q:Diesel hammer piling machine principle

- The guide rod type diesel hammer is pressed on the pile cap with a plunger as a hammer seat, and the cylinder is used as a hammer head to move up and down along the two guide rods.When in operation, the pile hanging in place pile frame in Longmen, then put the diesel hammer at the top of the pile, the hook will lift down the cylinder, and the cylinder sleeve off hook to the whereabouts of the piston, the cylinder will be closed in the air compression cylinder rocker pin until the pressure continues to fall outside the cylinder pushing hammer on the base of the fuel pump, fuel pump will be injected into the cylinder oil mist, oil mist meet high temperature gas burning immediately above, blasting, explosive shock down pile., to push the cylinder to cylinder to rise, fall along the guide rod, and the beginning of the second impact cycle.

- Q:What is the power of the pile driver?

- The power of the pile driver is between 50-150W, and the power of the different types of pile drivers is different.Pile driver is composed of pile hammer, pile support and auxiliary equipment. The pile hammer is attached to two parallel vertical guide rods (commonly called Longmen) at the front of the pile support and hoisted with lifting hooks. The pile foundation is a steel structure tower with a windlass at the back of which is used to lift the pile and hammer. A guide frame consisting of two guide rods is used in front of the pile to control the direction of the pile driving so that the pile can be accurately penetrated into the formation in accordance with the design orientation. The basic technical parameters of a pile driver are impact weight, impact kinetic energy and impact frequency. According to the motion of the pile hammer power source can be divided into hammer, hammer, diesel hammer, hydraulic hammer etc..

- Q:What machinery is used for piling?

- In fact, in some places with artificial, you can go to buy a wylong machinery piling machine equipment is good, driving fast and convenient and money

1. Manufacturer Overview |

|

|---|---|

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Korean Excavator Vibro Attachment

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Sets set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords