ZYC series ZYC120B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

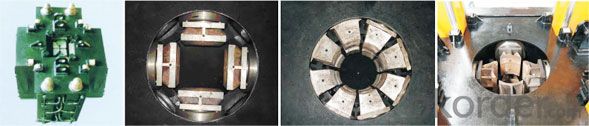

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 120 | Specifications for suitable piles (mm) | 200-300 ¢300 | |

| Max. Piling speed(m/min) | 3.0 | Max.lifting weight of Crane (t) | 5 | |

| Piling stroke(m) | 1.5 | Hanging pile's length (m) | 10 | |

| Max. Longitudinal pace(m) | 1.6 | Min.side piling space(mm) | 450 | |

| Max. Transverse pace(m) | 0.4 | Min.corner piling space (mm) | 1000 | |

| Max. Rise stroke(m) | 0.8 | Hydraulic Pump (Unit × Ml/Turn) | 1×63 + 1×25 | |

| Angle range(°) | 15° | Rated hydraulic system pressure(mpa) | 23(16) | |

| Intensity of pressure(tf/m²) | 8.8/8.3 | Weight composition (t) | Machine weight | 52±1.5 |

| Motor power (Unit × kw) | 1×22 + 1×11 | Angle range(°) Counter weight | 71.4 | |

| Total weight≥ | 120 | |||

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q:Code for installation and operation of pile drivers

- 4. Check whether the voltage of the power supply meets the requirements.5, according to the daily maintenance project to each department lubrication, maintenance.Five, pile driver in the work safety precautions:1, when the piling machine work, there should be special command. The conductor and operator should check each other's signals before they work. Work closely together.2, at the start of the bell signal or other applications, notify the staff around to leave.3, hammer and pile cap, pile cap and column (or pile) plane to pad, a connecting bolt should be tightened, and should always check whether there is loose.4. The starting of the pile driver should be adjusted from low gear to high speed.5, the pile driver in the work should be closely observed on the control panel current, voltage instructions. If abnormal sound or other abnormal conditions are found, stop inspection immediately.6, always check the temperature of the bearing and the bearing cover screws is loosening, should strictly examine the eccentric block coupling screw loosening, prevent the occurrence of accidents.7, sink, column (or pile) prohibited to stand around.8, piling machine with water, mud suction sink, should contact in advance with the relevant personnel, and take care of each other at work.9, long pipe column or pile and the installation of pile cap, the staff must wear safety belts.10 、 in the process of sinking, it is strictly prohibited to do mechanical maintenance work.Six after the stop of the piling machine, the power shall be cut off immediately, and the pile driver and motor shall be inspected and maintained.Seven, piling machine long-term disabled, should be kept in storage, the motor should be good moisture-proof protection, the control panel of the instrument, should be removed, storage, storage.

- Q:Pile up can not go down, how to deal with?

- The diameter of the hole pile is generally one to two smaller than that of the designed pipe pile, which can ensure the friction force of the pipe pile. Notice of design change shall be given to the design institute.

- Q:Which price is low for a pile driver?

- Specializing in sales of steel sheet pile, steel sheet pile construction, leasing, model complete, high quality, the construction of steel sheet pile, the price is more favorable, and exquisite design, honest and trustworthy business purposes, in full accordance with the market-oriented, large-scale, standardized operation requirements specification, through the implementation of brand strategy to build the core competitiveness of enterprises

- Q:Piling machines need to how much money??

- Hello, this is not necessarily, because the configuration is not the same, so the charge is not the same!

- Q:In the construction project, the pile driver can not be reached. What should the supervisor do?

- Stop. Check cause. Geological prospecting and prospecting

- Q:Rules for operation of impact pile drivers

- Two, piling construction process, before piling construction, in the construction site around the axis control network testing and protection, and do a good mark, and transfer procedures. The construction process is as follows: lofting pile two Pile Lofting pile pile on pile machine machine alignment machine to feed the pile piling pile verticality correction electric welding welding cooling design requirements to stop piling pile hammer machine machine three, hammer pile construction technology and quality control measures of each Pile Lofting after two times of review and correct aligned with the pile location insert, the first section is slow into the retaining pile verticality, upper and lower section pile after aligning welding, welding inspection by the parties after natural cooling time to meet the requirements after piling, final penetration and elevation controlled by the supervision, party a visa confirmation after the stop hammer machine construction. (1) the quality of the pile is guaranteed by 1. After each pile comes into play, the pile shall be discharged after passing the qualification evaluation (including the qualification certificate, the pile type, the date of manufacture, the appearance quality, etc.), and the pile shall be stacked in plain and not too high layers.

- Q:What's the difference between a pile driver and a boring pile driver?

- Piling machine generally refers to prefabricated prefabricated pile hoisting, with heavy hammer into the underground or static pressure into the underground machinery. The bored pile machine is the first hole, the next steel cage, and then pouring concrete machinery.The difference is that the pile in the construction of the pile driver is prefabricated.The bored pile machine is a cast-in-place pile on the spot

- Q:How much is a small pile driver with a 15 meter depth? When can I get a discount?

- A is specialized in Matlock piling machine, there are a variety of support, help you money... In Matlock is south of the Yangtze River's first professional production of piling.

- Q:CFG pile 22 meters deep, please tell me how many piles are required to flow out at the side of the slope. How about the 360 degree rotation of the pile driver?

- General 50-80, the best drill pipe can be connected, but the construction capacity of pile driver is limited, generally there are more than 20 meters, more than thirty meters, high rack will be able to play deeper.

- Q:Is the piling machine dangerous?

- Technical activity, not too dangerous, because I have seen others piling, the work environment is rather bitter, hot days, but also with a pile machine, there, one by one! The difficulty is not too great!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ZYC series ZYC120B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords