WEW Series Screen Display Type Hydraulic Universal Testing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main function:

l This series machines are mainly designed for tension, compression, bending and shearing test of metal materials and meet with the requirements of GB/T228-2002”Metallic materials-Tensile testing at ambient temperature”.

l This machine is also used for compression and bending test of nonmetal materials, such as cement, concrete and so on.

l Equipped with special auxiliaries, it can be used for mechanical property testing of fastener, wire rope and components.

l They are perfect testing instrument for project quality testing section, universities and colleges, research institution and industrial and mining enterprise.

Product features:

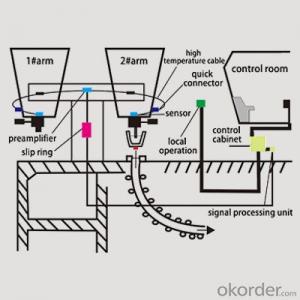

l Host machine consults foreign technique, it has compact structure and a rational layout, significantly reduces the overall height comparing the oil cylinder overhead.

l The machine owns hydraulic pressure sensor, which is with strong impact and long-life. Adjust the test space by turbine structure of mobile beam does not need rotation of screw when adjusting test space compacting the transmitting of chain. It makes complete separation between transmitting and postioning system, ensures the up and down jaws coaxial and the mainframe durable. Unique structure of screw gap eliminating can guarantee the continuity of the load test.

l Test data uses Access database management, which is powerful and convenient.

l Resered data interface can connect with the network directly and share resources.

l Independent hydraulic clamping structure can guarantee the reliability of the system; it will not hurt person for falling and ensure the safety of test personnel.

Product catalogue:

WEW-A Oil cylinder overhead type

WEW Oil cylinder underneath type Displacement of beams

WEW-B Oil cylinder underneath type Displacement of chain

Technical specification:

Specification | WEW-100B | WEW-300 | WEW-300B | WEW-600 | WEW-600B | WEW-1000 | WE-W1000B | |||

Accuracy of testing force | ±1% | |||||||||

Measuring range of force (kn) | 2-100 | 6-300 | 12-600 | 20-1000 | ||||||

Subsection of force | 1,2, 5, 10 | |||||||||

Accuracy of distortion measurement | ±0.5%F.S | |||||||||

Thickness of flat specimen (mm) | 0-15 | 0-15 | 0-30 | 0-40 | ||||||

Width of flat specimen (mm) | 40 | 70 | 70 | 75 | 120 | 80 | ||||

Testing space(mm) | tension | 550 | 750 | 620 | 800 | 690 | 650 | 620 | ||

compression | 500 | 650 | 550 | 700 | 620 | 600 | 580 | |||

Clamping diameter of round specimen (mm) | ф6-ф22 | ф10-ф32 | ф13-ф40 | φ13-φ60 | ||||||

Platen size(mm) | ф100 | ф130 | ф120 | ф180 | 200×200 | 210×210 | 205×205 | |||

Distance of bending by pass roll(mm) | 30-400 | 30-580 | 100-320 | 30-580 | 100-500 | 30-800 | 100-500 | |||

Maximum piston stroke(mm) | 250 | |||||||||

Power supply | 380V±10%,50Hz | |||||||||

Working environment | 10℃~30℃, relative humidity≤80% | |||||||||

Overall dimension (L×W×H)(㎜) | Host machine | — | 900×730×2270 | 900×730×2330 | 1070×850×2530 | |||||

B type host machine | 730×500×2000 | 800×500×1950 | 950×630×2265 | 980×650×2220 | ||||||

HPS | 1070×810×1730 | |||||||||

Weight(kg) | 1350 | 2700 | 2000 | 3000 | 2500 | 4100 | 3300 | |||

- Q:How does the fire pump pressure meter work?

- Imagine a floor of 3 meters, the 27 floor is 81 meters, so at least 81 meters to provide water pump pressure + atmospheric pressure, converted to 9.8*81*1000pa+1.01*100000pa=0.8938Mpa

- Q:Our unit has a 2.2kW water supply motor, running with EV1000. How to control according to the remote pressure gauge? Is to control the pressure within a certain range. Read the instructions, there is a process closed loop control parameters, but not quite understand.. please expert advice. It's best to say what parameters you need to change.Added 15 points to answer satisfaction.

- Method for controlling water pump by remote pressure gauge by Emerson frequency converter:The remote contact signal is first transmitted into the PLC, and after the arrangement, the starting signal of the frequency converter is uniformly sent through the PLC. PLC can judge or delay method to control the frequency converter start and stop pump action, to achieve not only switch control water pump, but also soft soft stop pump effect. As for the wiring, relatively simple, PLC contact is connected to the frequency converter to start, stop contact. Of course, the water pump protection circuit is completed. Logical control is done by PLC.Note: it is not suitable to control the frequency converter directly with the contacts of the remote pressure gauge. First of all, the contact jitter, will damage the inverter, and secondly, the number of contacts is not enough.

- Q:Y-100 what is the thread of the pressure gauge?

- Y-100 is the ordinary 100 meter diameter of the pressure gauge, 100 table diameter thread interface, standard is M20*1.5.

- Q:Vibration proof pressure gauge precision grade 1.6 and 1.5 difference

- The 1.5 level is the old national standardThe 1.6 level is the new national standard

- Q:What are the differences between axial pressure gauges and radial pressure gauges?

- Very simply. The thread that is mounted behind the surface is called an axial pressure gauge; the thread below the surface is called the radial pressure gauge.

- Q:Please show the hydraulic gauge is what pressure? Know the hydraulic piston area with hydraulic products area, how to calculate the pressure?

- Hydraulic gauge display is connected with the hydraulic oil pressure oil chamberKnow the piston area of hydraulic machine, but also have to know exactly the external load, also have to consider the mechanical seal resistance, resistance and other factors, to get an ideal external value divided by the piston area can get relatively accurate pressure value.

- Q:For example, a 1.6 mpa. How do you measure it?!

- Multimeter hit 2K (digital table), measuring remote table above three terminals in any two terminals: if it is 400 Ou mother, these two is high-end, low-end, and the rest that is the sliding end (middle end). Next, the access line, if the clock indicating pressure increases, while the display is declining, the high-end, low-end swap line.In general, three terminals, the bottom is the middle end, the middle is high-end, and the top is the low-end. Consistent with the electric contact pressure gauge.Have a try.In general, three terminals, the lower end of the remote meter to measure the above three terminals in any of the two terminals, the top is the low-endIn order to measure the current, the voltage of the standard resistance is measured, and the current is calculated according to the voltage. The output between 4 and 20mA depends on the type of the remote meter. Analog remote meter is generally 4 to 20mA output, to determine whether the pressure gauge is normal, if it is digital remote meter, that is, high-end 24V voltage, multimeter is not measuredA high, medium, and low end pressure gauge shall be a three position contact type control pressure meter. If no signs are available, you can use either the ohmmeter or the buzzer test of the meter. Use the pencil first low limit hands to contact with the actual pressure gauge contact is closed, with a multimeter measuring three end exchange both ends of the middle and low end, the rest is high, then closed contact separately, the high pressure closed with the actual pointer to pointer, and then test interoperability both ends of the middle and high, so you can points out.

- Q:What are the black pointers and red pointers in the gas pressure meter? How do you read them?

- Black pointer is pressure readings (direct reading), red needle is to adjust the lower limit pressure for action.Double needle pressure gauge is mainly used for vehicle are used to measure the hydraulic system or gas cylinder pressure, can also be used without corrosion to copper tin alloy, Aluminum Alloy brazing, pressure measuring various medium non crystallization and solidification of the. The twin needle pressure gauges can simultaneously measure the pressure of two identical or different ones (the difference generally should not be greater than the limit of 1/3 in the scale range).Principle: the instrument consists of two sets of independent measuring systems and indicating devices.The instrument works based on the elastic deformation of the spring element (the spring tube in the measuring system). The pressure of the measured medium, so that at the end of two after the spring tube of each corresponding displacement, with the help of the rod drive gear transmission and amplification by the fixed gear shaft of the black and red pointer of the two measured values respectively in the disc of show.

- Q:The indicator of the extinguisher pressure gauge points to green, indicating whether the extinguisher pressure is normal or not?

- The pressure gauge pointer to the green is normal, below this pressure into the shortage of red belonged to the inflation pressure.

- Q:Detailed explanation of working principle of Bourdon tube pressure gauge

- Mechanical deformation and mechanical transmission

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WEW Series Screen Display Type Hydraulic Universal Testing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords