YJS-600 Digital Display Type Well Cover Hydraulic Compression Testing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ⅰ、Main functions

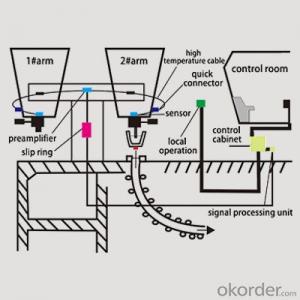

This machine adopts hydraulic load, manual control, electronic measurement and digital display and has the function of force peak value preserving and manual eliminating force peak value. It is applicable for compressive strength test of well covers, which are made of steel fiber reinforced concrete and cast iron.

Ⅱ、Products catalogue

YJS-600A Standards:CJ/T121-2000、CJ/T3012-93

YJS-600B Standards:JC889-2001、JC/T948-2005

Ⅲ、Main Technical Specifications

Tyoe Parameters | YJS-600A | YJS-600B |

Maximum testing force | 600kN | |

Accuracy of testing force | ±2% | |

Testing space(㎜) | 1250×300 | 1280×260 |

Pressure plate size(㎜) | Ф356 | Ф356(Manhole);500×200、250×200(Water cover grate) |

Piston stroke(㎜) | 250 | |

Power supply | 380V±10%,50Hz | |

Overall dimension(L×W×H)(㎜) | 1600×1000×1730 | 1600×1000×1800 |

Weight(kg) | 2500 | 4000 |

- Q:What's the difference between the pressure gauge and the bellows pressure gauge?

- Big differenceThe bellows gauge is only one of the pressure gaugesA pressure gauge is a general term

- Q:How to use the car fuel pressure gauge?

- Series connected in the oil circuit

- Q:The pointer always points to the 0.5bar seismic pressure gauge, can not return to zero, the free end inside the broken? What's the reason then? Is the pressure too great?

- Proof above the table generally have a rubber plug, use is to cut with the atmosphere. If you are not cut, long time work, the pressure in the case. When the pressure is released in the form of discharge after the shell pressure, so just. You put a rubber plug off, if not back to zero that is bad.Yes, it's not rubber. It's a small valveThe tables are required to be installed vertically or near vertical and sealed when removed

- Q:I want to use a frequency converter and a remote pressure gauge to control a submersible pump, using the on-off control, constant pressure water supply, how to connect and set up

- I think you may be wrong! More (money, easy) scheme is using 1 transmission pressure gauge + inverter, constant pressure control. But not switch control. Control is continuous.The only output switch contact transmission pressure gauge is the electric contact pressure gauge. Inside a rheostat, with the change of pressure, sliding rheostat output resistance change. But it should be noted that this watch is certainly three line connection (don't understand NO/NC/COM).Like ABB, ACS510 series and so on, you can access to the X1 2,3,4 terminal, so as to achieve constant pressure control, specifically, you have to look at your inverter manual

- Q:What's the notation for a pressure gauge?

- Y pressure gaugeZ vacuumW temperatureN shockP diaphragmS bimetalXC magnetic contactXC magnetic induction contactXG induction electric contactTZ resistor remote transmissionTT differential transmissionE film boxA ammoniaXD photoelectric contactSG inductance transmitterSS bimetallic single indicationT specialM diaphragmO oxygen useB stainless steelL thread typeF flange typeZ shockF corrosion resistanceFZ corrosion proofD positioningL needleSST pressure transmitterPD pressure relayCYS differential pressure gauge

- Q:What is the coefficient of error for the 2.5 grade pressure meter?

- Table 2.5% of the range is an inaccurate thermometer

- Q:What are the black pointers and red pointers in the gas pressure meter? How do you read them?

- This is a two needle pressure gauge. The black pointer indicates the pressure value in the current pipe. The red pointer is used to set the maximum pressure as a warning function. When the work pressure, the black pointer, approaches the red pointer, notice that the pressure has reached the ceiling.

- Q:The role of the pressure gauge on the train

- There are two pressure gauges on the train locomotive, called "balanced air cylinder, double needle pressure gauge", for monitoring the pressure of the equalizing cylinderThe emergency brake beside the carriage also has a pressure gauge in the car. Mainly to look at the pressure of the car air cylinder, referred to as wind pressure.Additional knowledge: how to use the emergency brake valve?When using the emergency brake valve of the vehicle, it is not necessary to break the seal first, and immediately pull the valve handle to the fully open position until it is fully opened so as not to stop or close. In case of a spring handle, you must not let go before the train stops completely. In the long slope, we must look at the pressure gauge, such as gauge is determined by pressure drop 100Kpa, shall not use the emergency brake valve (except when the angle cock is closed).

- Q:What are the thread connections of the pressure gauges?

- There are three sizes of M10*1, M14*1.5 and M20*1.5 specifications

- Q:Fix a false SUPOR electric pressure cooker E4 fault, after inspection, the pressure switch is not in good contact. Replacement repair, but do not know how to adjust, worry about not repair to the original machine state will explode! Ask the heroes what coup adjustment!!!

- The pressure switch is adjusted to the air valve. When the gas is out, it should be broken off. A little gas can be closed and the air valve is broken. Handshake, that's how I got it

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

YJS-600 Digital Display Type Well Cover Hydraulic Compression Testing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords