waterproof wpc flooring decking board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Engineered Flooring | Place of Origin: | Zhejiang China (Mainland) | Brand Name: | CMAX |

| Model Number: | CMAX | Technics: | Wood-Plastic Composite Flooring | color: | Coffer,black,brown,wood,tea,white,customized. |

| feature: | anti-slip surface,low maintance cost | width: | 140mm | thickness(height): | 30mm |

| surface grooves: | narrow grooves,wider grooves | surface treatment: | Sanding,Embossed,Scratched |

Packaging & Delivery

| Packaging Detail: | Packaging: wrapped with PE plastic film and on wooden pallet Size(mm). |

| Delivery Detail: | 7-12days after order confirmed |

Specifications

1.Natural & Beautiful wood look 2.Easy install & clear,low maintance cost 3.No trip hazards,recyclable

China waterproof Anti moth ANTI-UV dedicated composite wood boards

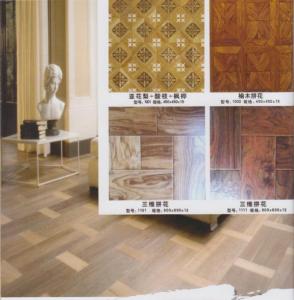

Product pictures:

Product information:

Material | Wood Plastic Composite |

Ingredients | 30% HDPE+60% Waste Wood Fibers+10% Auxiliaries |

Colors Available | Coffer,black,brown,wood,tea,white,customized. |

Bottom | PE plastic Base |

DIY Snap Interlock Puzzle Tile | Easy for Installation |

Applications | Patio, Balcony,Terrance,Walkway,Boardway Decking,Pool Decking,Sauna Room & other Public Areas |

certificiate | CE. SGS .INTERNEK .ISO9001 .ISO14001

|

product features:

1.Natural & Beautiful wood look 2.Easy install & clear,low maintance cost

3.No trip hazards,recyclable 4.Long lifespan & UV stable,No wrapping,No rotting

5.Great drainage 6.Eco-friendly,anti-slip surface

*Easy cleaning and maintenance :No need of a specific treatment .just a usual water washing is necessary

*Safety:Splinters free and slip resistant Free of any toxic product

*Colours may slightly change,photos are not not contractual

*Resistant to scratches as oak resistance

*Very low colour variations

- Q:Dnf nothing in the environment how to run the floor -_- || own attack helpless can not remember the floor order, each time have to pay b -_- ||

- Very simple, now pao'ge'zi only three graphs, you can watch the picture run. Remember the first three on it!

- Q:Interior laying

- Total number of sheets = actual paving area (m2) ÷ monolithic tile area (m2) x loss 1.05% (TB train diary tiles)

- Q:Lived for almost a year, with Bi Lizhufu trace of grams of the long-tan of the floor of the floor of the wax to fight their own, but after the floor appeared a block of the spot, which is the reason, how to solve it? The Thank you! More

- The reason for playing is not to grasp the various kinds of wax drying time (Biluo beads dry time is very fast. With the uneven spray, it is easy to spend) Once the flower, how to solve it? Only with the wax removal agent, the drift of the wax removed to re-call (do not use gasoline, do not try to use wax to cover, these methods are not feasible.) Another trace of the past Henden magic outside, suitable for ordinary home use of the floor wax is better to play the wax. Natural wood wax better fight, with the people do not have to worry about playing flowers.

- Q:Sims 3 There is a mission in the Middle Ages to clean up the floor

- Pro, I also play it, you click on the priest itself, there will be scrub the floor and thought the options, hoping to help you, play happy

- Q:ok so i was watching routines on floor and i was just wondering, because it seems highly unlikely people could do the things gymnasts do on regular floors, so are the floors used for floor event like springy floors?

- Gymnastics floors have springs in them. They are about 4 tall and they cover the entire bottom of the floor. =]

- Q:The kitchen floor slants from the outside wall toward the center.

- Better Questions Yield Better Answers I've had a lot of practice leveling homes, floors, and rebuilding floors. I'm afraid you've not provided enough detail here. First -- what kind of floor? Wood joists? Cement? Second -- What kind of foundation? (or is this a mobile home?) Third -- Do you know what is causing the slant? And - while you state it slants from outside wall toward the center, you didn't give us any indication whether that is a slant uphill, or downhill. Fourth -- is there any damage to the structure? How you go about re-leveling the floor will depend greatly on how you answer these questions. For example -- if this is a concrete floor - you're most likely going to have to call in a mudjack crew (if it is ONLY the floor that is sloping), or helical foundation repair (if the slant is downhill to the outside wall, and the foundation has in fact settled). Usually the same business can do either type of repair, but which type depends on the answers. If this is a wood joist floor, then we'd need to know if there is, again, a foundation problem, or rotten joists, etc. -- or perhaps its a couple of bowed floor joists. Also -- what is under the floor? Do you have a crawlspace, or basement? (You wouldn't have either if this is a home built on a cement slab - but you didn't give any hints) If this is a problem with rotten joists, they would have to be replaced, of course. If this is a problem with broken joists, they can be repaired, or replaced. If this is a problem with bowed floor joists, they can be repaired. If this is a problem with structural supports they can be releveled. If this is......and the list goes on, hehehehe. Feel free to email me, if you'd like to discuss this project further. I can walk you through what will need to be done, but we have to have more details. Good Luck

- Q:I've seen in some retail spaces a glittery floor and I would love to know what it is! Or any suggestions for a glitter/sparkly floor?

- these floors are covered with an enameled paint product made by Rustoleum. the kits to do this can be purchased at Home Depot or Lowes. they are designed for garage floors and must be used on concrete floors. the cost is about 100.00. the concrete must be prepped first for consistent coverage. a pro should be consulted. good luck.

- Q:Why do price floors lead to surpluses? What is an example of a price floor?

- An price floor will lead to a surplus because even though the firm would like to lower prices to match the equilibrium price it cannot do so legally. For example, if I am a farmer selling corn that costs 100 dollars to produce the simple market clearing price would be 100 dollars. At a price of 100 dollars the quantity supplied equals the quantity demanded. Now the government hears farms are going out of business. It is in the governments best interest to ensure farms do not close so they put a price floor of 120 dollars into place. Now the farm can sell their corn at a minimum of 120 dollars. Remember the cost to produce the crop = 100. If it is sold at a minimum of 120 then there will be a 20 dollar surplus.

- Q:Anthracene `` what the room is now decorated with wood?

- Anthracene `` what the room is now decorated with wood?

- Q:Carpet or hardwood floors?

- No floor is perfect. Here are some pros & cons to help you decide. There are several new carpets that guarantee against permanent pet stains. There are some with odor guard that will prevent pet odors and stains. You still need to vacuum often. Hardwood easy to clean up pet hair. Can be stained and ruined by pet urine. Will not be scratched by normal toe nails If the correct finish is used, Look for aluminum oxide. Tile is a good choice, just be sure to seal the grout. In the wood look, consider a quality laminate. Or consider a new product from Armstrong called Fashion Plank. It's water proof, very hard to scratch. Looks really like wood.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

waterproof wpc flooring decking board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords