Hot Sale Wood Grain Laminate Flooring

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- One Container m²

- Supply Capability:

- 300 Containers m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details of the Hot Sale Wood Grain Laminated Flooring

Wear Layer | 0.30mm, 0.50mm |

| Thickness | 4.0mm, 5.0mm |

| Plank Size | 101.6mm x 914.4mm/4'x36', 152.4mm x 914.4mm/6'x36' |

| Backing Layer | Recycled PVC & Virgin PVC available |

| Edge Detail | Squared edge & Beveled edge available |

| Surface Treatment | UV coating |

| Surface Texture | Wood embossed |

| Installation | Click System |

Specifications of the Hot Sale Wood Grain Laminated Flooring

(1)Perfect Color

(2)Top Quality GuranteeAC5

(3)Free Samples for Global Market

(4)Perfect Support Ideas

Packing of the Hot Sale Wood Grain Laminated Flooring

For 1215*195*7mm,10pc per box,70boxes per pallets,20 pallets per 20'fcl

For 1215*195*8.3mm,8pc per box,70boxes per pallets,20 pallets per 20'fcl

For 1215*195*12.3mm,6pc per box,65boxes per pallets,20 pallets per 20'fcl

Volume of the Hot Sale Wood Grain Laminated Flooring

For 1215*195*7mm,about 3316.95sqm per 20'fcl

For 1215*195*8.3mm,about 2653.56sqm per 20'fcl

For 1215*195*12.3mm,about 1848.01sqm per 20'fcl

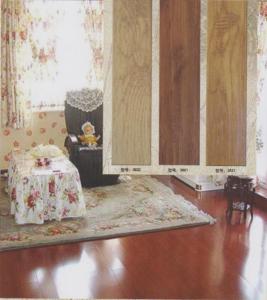

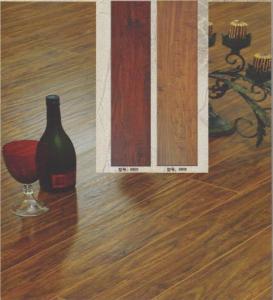

The following pictures are for reference

- Q:I am having laminate floors installed on my 1st floor concrete slab. They keep testing the himidity. It has been to high. I have been running two dehumidifiers for 2 weeks, tore out my laminate floors.....What else can I do? Should I put a sealer on my floor? What kind- a waterproof or a water base????? HELP ME!!! THANKS!

- laminate is a thin wood veneer,,,,go with hardwood flooring,,,,solid and will not peel,,,you need to seal the concrete AND use a moisture barrier so the floor wont warp. BUT if you have high humidity, look to other flooring options such as ceramic tiles.

- Q:How many square of a box of wood flooring

- Usually two more square, each company board specifications are different, the specific square is also different

- Q:What is the size of the parquet floor?

- 450 ****** 610 round the floor of the professional parquet, you nothing to OKorder see.

- Q:I have tile floors and in the middle of the tile in the living room there was carpet. I had the carpet taken out and laminate floors put in. The trim between the tile and the laminate keeps popping out. When I had the flooring guy come out to fix it for the third time he said it was always going to do that because the wood was thicker (higher) than the tile. Is there something else I can do besides this stupid piece of trim?

- There are pieces of trim that have one thickness on one side and another thickness on the other for this exact reason where one floor is higher than the other. This trim allows for a smooth transition from one height floor to another. I have had it in my house for years and it never popped out. Mine is oak. Your installers obviously are using the wrong trim for this application as there is a trim for this transition. Go to your local home improvement store and you can see what I am talking about. I wish I had the correct name of this trim to make asking for it easier for you. But, I am sure once you describe the problem, they will know where to direct you. Good Luck

- Q:is there soil on the ocean floor

- There are silt / clay deposits out toward the middle, and there is sand and other coarse deposits near shore. The heavier the particle, the sooner it settles onto the ocean floor when it is carried there by a river. And it's called sediment, not soil. Soil is a dry land phenomenon.. Plus, where there are plate boundaries, magma comes up and cools, forming basalts, etc.

- Q:These wood flooring are processed through the radiation you, peace of mind to do this how to do more

- No radiation, but may contain formaldehyde, solid wood does not contain formaldehyde, strengthen and composite floor contains a small amount of formaldehyde, but within the national standard, the human body is not harmful. In addition, in the paving solid wood flooring, strengthen, when the composite floor may be through the paving adhesive into formaldehyde. After the decoration of the house must be empty for a period of time to stay

- Q:I just had tile put down in my kitchen. And I hate it, Some of the squares are cracking and the floor is hard to keep clean.I need to know another flooring that will be good for high traffic in the kitchen. The main flooring under the tile is plywwod that's what all the floors are made of in my house. Is that gonna be a problem no matter what floor I choose?

- Kitchens are high traffic areas and all flooring will take a beating over time. Tile is usually the best option but vinyl, hardwood, cork, concrete, paper bags?!?(saw this on another ?) and more are making the way into flooring. Research your options. As for the tile. You shouldn't put down tile directly over plywood. You will need to redo it with a cement backer board like Hardi-Backer or Durock.

- Q:Three layers of solid wood flooring panel, core layer and the bottom of what are the requirements?

- 1 three-layer solid wood flooring panel thickness is usually 3-4mm or more, with a floor surface layer of material should be consistent. Surface wood requirements are very strict, have a good stability, color, texture and decorative performance for consumer needs. 2 The same batch of floor core layer requires the same or similar materials. 3 commonly used species: poplar, pine, birch, basswood and so on. Common thickness of 1.5 ~ 2.5mm. When the selection of materials to avoid the dead, rotten 笭 arc udie old Li mixing pad some rogue, cracks and other defects. The bottom processing is usually done using a peeling process.

- Q:whats the easiest way to get it off the floor . been there since like 1984??????????

- There is a special tool you can find in a Home store. Ask them. Would be worth buying if you have a lot. I have seen it being used, sort of like a scraper on a long handle. Doubt it would be very expensive.

- Q:I have laminate flooring through out my apt. including my bathroom. Well, my toilet overflowed and I need to disinfect the floor. I do not own a steam mop. Is there a cleaner I can use that will disinfect and not harm the floor?

- Get some laminate floor cleaner at a home improvement store. It usually contains alcohol. I like to apply it with a Rubbermaid Reveal mop. They sell them at Walmart and other places. You put your own cleaner in the reservoir and it has a pump handle to spray it on the floor (like a swiffer wet jet). Instead of disposable pads, it uses a washable microfiber pad.

1. Manufacturer Overview |

|

|---|---|

| Location | Changzhou |

| Year Established | 2008 |

| Annual Output Value | USD 5000000 |

| Main Markets | America 50%, Asia 40%, Europe 10% |

| Company Certifications | ISO9001:2000; ISO14001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 5 |

| Language Spoken: | English |

| b)Factory Information | |

| Factory Size: | 100000m2 |

| No. of Production Lines | 5 |

| Contract Manufacturing | |

| Product Price Range | USD4-USD8 |

Send your message to us

Hot Sale Wood Grain Laminate Flooring

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- One Container m²

- Supply Capability:

- 300 Containers m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords