Tower Crane TC7021 Find Dealer in Malaysia

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

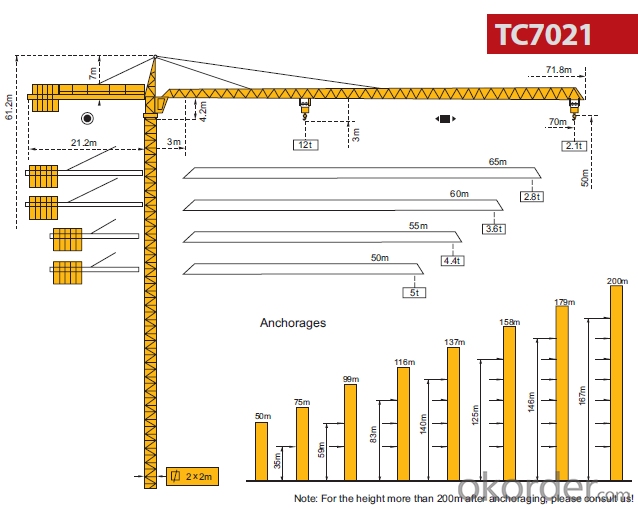

Structure of Tower Crane TC7021 Description

Feature: Tower Crane

Condition: New

Application: Construction

Max.Lifting Load: 12T

Max Tip Load:2.1T

Independent Height:50M

Max Lifting Height: 200M

Span: 70m

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: TC7021

Packaging & Delivery of Tower Crane TC7021

Packaging Detail: Nude package

Delivery Detail: 25-30days

Main Feature of Tower Crane TC7021

1) The tower crane have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition.

2) This kind of crane adopts standard section hydraulic lifting and connecting, and can decide the crane height according to the actual height of the building, and at the same time the lifting capacity will not be affected; The max. attached height can reach 200m.

3) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

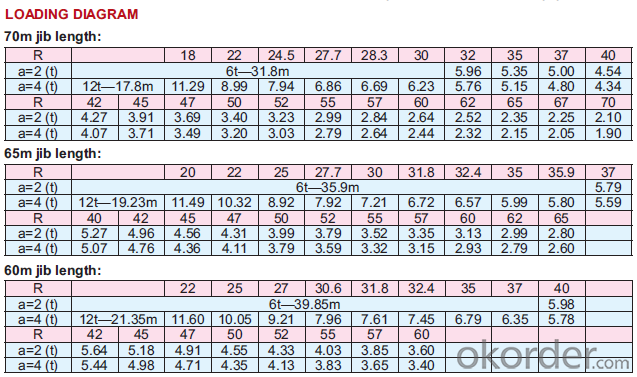

Specification of Tower Crane TC7021

Technical Sheet for TC7021

Free standing height (m) | 50 | ||||

Max height with attachment (m) | 200 | ||||

Working range can be adjusted(m) | 40、45、50、55、60、65、70 | ||||

Min working range(m) | 2.5 | ||||

Max lifting capacity(t) | 12 | ||||

Tip load @ 70m(t) | 2.1 | ||||

Hoist mechanism (VFD+PLC) | Falls | 2 | 4 | ||

Lifting capacity(t) | 0-3 | 0-6 | 0-6 | 0-12 | |

Speed(m/min) | 0-80 | 0-40 | 0-40 | 0-20 | |

Motor | YZPBF250-4-55KW | ||||

Trolleying mechanism (VFD+PLC) | Speed(m/min) | 0-56 | |||

Motor | YPBE132M-4-7.5KW | ||||

Slewing mechanism (VFD+PLC) | Speed(r/min) | 0-0.6 | |||

Motor | YLEW112M-6-120N.M×2 | ||||

Climbing speed(m/min) | 0.5 | ||||

Counterweight(t) | 23.6 | ||||

Mast section size(L×W×H)m | 2×2×3 | ||||

Working temperature | -40-+60℃ | ||||

Total power (KW) | 95 | ||||

Power supply requirement (KVA) | 255KVA for generator | ||||

Cable type ( within 30 meters from site power source to lower electric box of tower crane ) | |||||

Startup voltage & current | 380V×95%=361V 260A | ||||

Rated working voltage & current | 380V 146A | ||||

Images of Tower Crane TC7021

FAQ of Tower Crane TC7021

Q: What is the principal to quote the right tower crane to the client?

A: First, we need to know clients’ requirements. Normally the following information should be clarified by the client: max lifting capacity, height (height under hook), tip load and jib length.

Second, we need to know what the foundation requirement from the client is. (Fixed/undercarriage/ undercarriage with traveling system), mast section type (panel/integrated), power supply source (voltage, ampere and frequency), the distance between the machine and power supply……

Third if there are special needs, we could suggest proposal according to clear data provided by the clients. End-user, as construction machinery buyer, knows the site situation well and should make decision, such as the machinery specification, type…….

Q: What about our tower crane's warranty?

A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane?

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients’ requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.

- Q:Is a mobile crane allowed to operate in an inclined plane?

- NO, absolutely not. If the machine is not level, it could fall over. The only way, if it has to be operated on an incline, is if the machine has leveling jacks such as many modern, mobile cranes have.

- Q:Its on of the biggest helicopters in 1952-1955 I just need any information via you, internet, or even blue prints!I highly doubt that blueprints are probably destroyed

- It never really took off as it was quickly replaced by the CH-54 Tarhe, but here is what I found…

- Q:Can the tower crane personnel install the construction elevator?

- As for the hoisting equipment, the licensed crane erection worker can install the construction elevator.

- Q:My boyfriend's a little sick right now, and he's going to have a surgery over summer. I'm in the process of folding him 1000 cranes (like the Japanese legend), and in every crane I wrote a message. I have a list of all the messages so far. I'm not sure how to give it to him, though. 1000 cranes is a lot of cranes... and I don't want to make him carry a big heavy box or anything. I also want him to be able to read the messages... something I didn't think of much when I decided to write them on the paper I folded the cranes with...Anyway, I was thinking about a scrapbook or something. But that would be a really big scrapbook. And I'd have to probably write out all 1000 messages again in it... Plus, I'm not sure if I can find a scrapbook with enough pages.Any ideas?

- 3 Aw that is so sweet, maybe you can make a mobile or tie them all on a string. i also really like the scrapbook idea, maybe u can make the cranes small so that they all fit in the scrapbook.

- Q:Tower cranes sometimes have very long booms, but seem to usually have fixed counter-weights at fixed positions behind the cab. Why doesn't it flip backwards when there is no load, or flip forwards when a load is way at the far outward end of the boom? It seems to be a very large range of moment arms given that the counter-weight has a fixed one.

- I think the counter weights are connected to a pully system that directly interacts with the boom and hook movement. This way it can put more or less pull on the weights according to the amount of weight or position of the weight on the crane.

- Q:i need to write a 2 pg paper on this, and i cant even begin

- Stpehen Crane used interesting literary techniques such as colorful metaphors which can easily be identified in eg like knowing eyes which represent the people of Dunnet (ammons, 84). Another literary technique he uses often is irony which is seen in chapter with Mrs. Todds variety of personality which shows how Mrs. Todd has this varied personality(eden, 141). Other literary techniques shown are comparisons and contradictions, dramatic personification and powerful paradox.

- Q:When the tower crane top height is more than meters

- (two) lifting equipment installation with lifting weight 300kN and above; demolition work of climbing crane within height 200m and above.The installation and disassembly of the tower crane in accordance with the provisions of the above provisions shall be verified by the expert panel.

- Q:Ok so I am now on my laptop in my room, in my bed and I am bursting for the loo, like really bad. I knew before I went to bed there was a crane fly in the hall (outside my room), so I made sure I went to the loo before I went to bed. But me being me I need it again but i have phobia of those dreaded crane flys. I went out and put the light on making sure 2 close the bedroom door, and then it started to fly towards me so I ran back to my room. I need help cause I don't know what to do?I am petrified of them. My fiance would normally move it for me but he is on night shift tonight.The last time this happend I stayed up all night and went to the loo at 7 am when my daughter got up, I don't want to do that again considering it is only 1:44 am over here

- No dude, youre confusing two different species. Daddy long legs- or Harvestmen, as they're known in the UK- are the ones with powerful venom, but fangs too short to bite a human being. Crane flies, which look kind of like a flying daddy long legs, are a species that feed one nectar only. They are not carnivorous, and they don't have fangs, or a stinger, or any other means to defend themselves. The females have a tool on their abdomens for depositing eggs. It looks kind of like a stinger, but it is not one, and can do no harm at all.Daddy long legs-spiders can not fly. Crane flies don't even live long enough to eat. Most of the species of crane flies live long enough to mate, and nothing more. Theres is no reason to fear either species. Oh, and they don't eat mosquitos. That's a myth.

- Q:i have 5 tower cranes outside my window at different construction sites and they all position their cranes the same direction at the end of the day. is there a reason for this.

- It might be that specific company or something. I'm on the Las Vegas strip right now, and there are dozens of cranes pointed every which way.

- Q:How do you apply for it? What are the specific requirements?

- These do not worry about you, these large machinery is a professional installation team, security, demolition,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane TC7021 Find Dealer in Malaysia

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords