Steel Pipe Fittings Butt-Welding Concentric reducers high pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Concentric reducers

Features standards and products of our Butt-Welding Concentric reducers:

Features of Butt-Welding Concentric reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Concentric reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Concentric reducers:

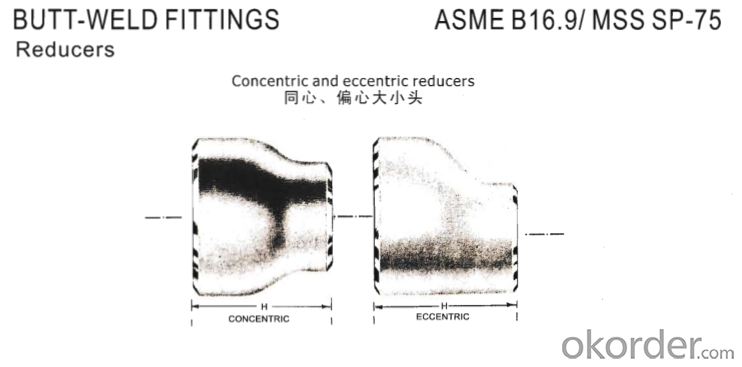

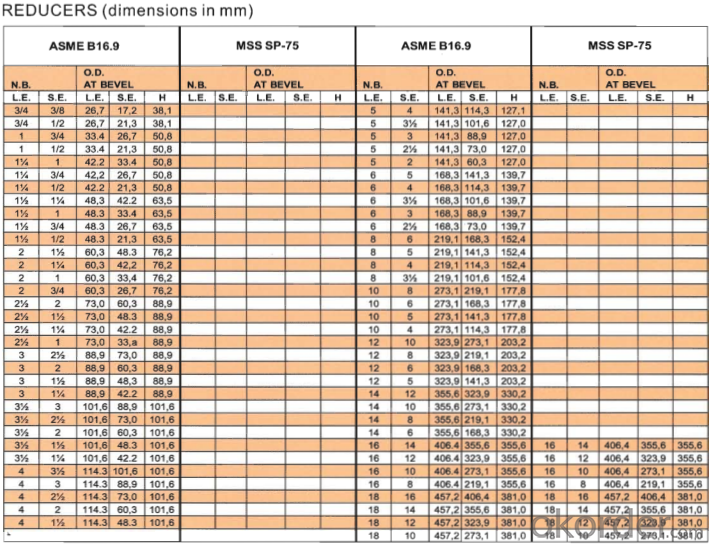

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Concentric reducers:

Packing of Butt-Welding Concentric reducers:

FAQ of Butt-Welding Concentric reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:I had a stack able washer and dryer and the dryer broke, so we never got another one. I have a standard washing machine and we hang out clothes to dry (we only have 210/220 plugs and can't get a dryer). I use Gain or Wisk detergent and my clothes rarely smell good. Should I buy a smell enhancer for laundry?

- Shark branded brass fittings have worked nicely for me; they have a small C wrench that enables fast switch-out of the fitting, for pipe replacement, or fitting configuration changes and they fit CPVC as well as PEX (and K copper too I think?). Freezing is a problem no matter what material is used: all necessary prevention must be taken. Anything will be rendered useless if it gets frozen.

- Q:I have an automatic 2005 Toyota Matrix with power locks and windows. For some reason, when my husband pressed the beeper to unlock all the doors, all the doors unlocked except the driver side door. I thought maybe it was a fluke, but this morning, when I unlocked the car, it did the same thing.Also, I have the car set so that when it is put into gear it automatically locks all the doors. Again, the doors all lock except the driver side. Even when I push the button to lock the doors that is on the door, all the locks lock except the driver side.I didn't know if maybe a weird button was pressed or if something is wrong with the lock. Any ideas? And also, if something is wrong with the lock, any suggestions on getting it fixed? price? or any other relevant info would be great!!! Thanks.

- yes i would put a rubber washer in, by the way we call them copper Ferrel's, or compression rings,

- Q:what are the best fire extinguishers for the home?

- high voltage but i dont know how much energy it really has if u stored the lightning bolt in a capacitor for example it might not last long, when u take a t shirt off and see a spark thats around 15000 volts, when you hear a click from a static shock thats around 8000 volts, search it up, but theres no real current in these static zaps

- Q:i have very rough hair..what should i do?

- No. You can make a mold out of sugru (an air drying silicone substance), or make a substance called oogoo, which is 100% silicone caulk mixed with cornstarch, and some add spirit minerals.

- Q:Hello. I ve recently used a gas mask to go into a asbestos ridden area. However my clothes have been contaminated and so has my mask. How would I go about cleaning them safely? My mask and all clothes are in a garbage bag currently waiting. I am a college student so would prefer a cheap method to clean my clothes (most importantly my mask). Do I need to bring them to someplace special or can I do it safety at home? Am I safe to use the mask again if I remove the dust outside wearing another mask? If I were to enter the area again should I just use contaminated clothes? Help please!

- Try JP cycles They should have what you need. But good luck with the $75 budget. You are aware that HD stands for hundred dollars right?

- Q:I've a dishwashing job at a restaurant, I don't like to wear those annoying rubber gloves that make my hands sweat. Is it really necessary to wear gloves?

- Within the AHU ther are whats called Dampers a device that is designed to stop the spread of fire normally on the air intake side of the ahu as opposed to the extract side of the system. The BMS is where the system programming is and there are many variations of different logics and situations. Simply you will have a smoke detector of some kind in the AHU, and when smoke is detected it sends a signal to the BMS and closes the Damper and / or the Air intake Fan. Probebly from the design of the system smoke detectors are placed in the higher risk places of the system. Hope this helps, I work on these systems all the time. Neil

- Q:1)Whats the function of the umbilical cord2)What are the function of the cartilaginous rings?3) Can you guys tell me special safety procedures that must be followed when performing dissections?4) Why are the Liver so big5) Why are Small intestines so long compared to other parts in body

- If you can really turn off the fire, I would say let it burn and keep working on Yahoo. If there's a fire burning that you need to extinguish, get away from the PC and put out the damn fire. How do you expect to answer questions on here when you have no house, no computer and your DEAD?

- Q:fender system one guitar tremolo lock collar?

- I would look to see what the problem was sometimes it's not a fire that sets the alarm off. And if it was a fire I'd get my fire extinguisher.

- Q:Do patients wearing a heart pace makers need to stay away from microwave ovens?

- For what it's worth BSP threads have 11 threads per inch, where it's 2 inch, 1 1/2. or 1 or 3/4.1/2, 3/8.1/4. BSP threads aren't interchangeable with NPT threads NPT threads are often used on high pressure such as hydraulic hoses gas fittings. Cheers!

- Q:I have been with my girlfriend for four years and if we have a terrible argument and I end up making her cry, I feel like the biggest bastard and try to apologize and comfort her, but whenever I try to, she locks herself in the bathroom for over an hour and avoids speaking with me. Half the time I sit there by the bathroom door, waiting so I can fully apologize and after wards she doesn't try resolving anything or explaining what I did wrong to upset her and she just goes straight to bed leaving me baffled and unsure of what to do next. Why does she do this? It makes me feel so helpless half the time, because I really dislike upsetting her and seeing her cry.She does the same thing if I watch a movie with her, where she finds it heartbreaking. She'll quickly rush off into the bathroom and then a minute later she'll come out and it'll be obvious she was crying and she'll deny it. Do you think she just doesn't like showing her feelings in front of me?

- you decide on a set of tension gages for it once you are trying this ,you may desire to have extra freon than you have tension,and which will reason an in-stability interior the device,and not enable it to kick back genuine good,that's why air con artwork could desire to be left people who try this for all time,it is going to hold relating to the comparable quantity of freon ,yet without the gage on it,you will possibly not get it to kick back precise,there ought to be plenty tension on the extreme edge of it,and much on the low edge,if not it wont ever cool precise,in case you get too plenty in it,it may desire to lock the compressor up on it additionally,good success with it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding Concentric reducers high pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords