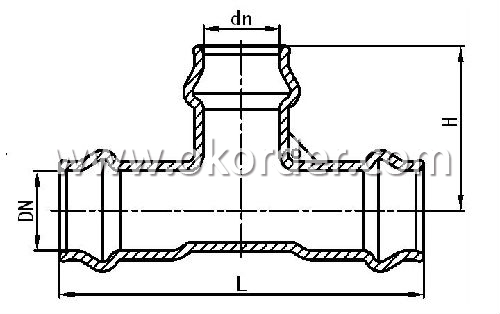

ISO2531 All Socket Tee Of Manufacturer From China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000Pcs/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of ISO2531 All Socket Tee Of Manufacturer From China

1. Sureface treatment: epoxy painting or according to the customer's request

2. Standard: ISO2531 EN545,EN598,BS4772

3. Size: 80-2000

4. Inspection: SGS inspection

5. Pressure: PN10,PN16,PN25

6. Material: ductile iron GGG507,ductile iron 450-10,450-12

7. Delivery Time: 20-30days or as per clients' request

8. Sureface treatment: Zinc plus Bitumen external+Cement Mortar internal

9. Accesories: Gaskets,bolts and nuts.

10. Rubber Gasket Material: EPDM, NBR, NBR

11. Mechanical Properties: Tensile Strengh: ≥420 MPA; Elongation: ≥5%; Hardness: ≤250HB; Yield strength: ≥300 MPA

12. Hydrostatic Test Pressure: DN 80mm-DN 300 mm: 25 bar; DN 350-DN 600 mm:16 bar

Applications of ISO2531 All Socket Tee Of Manufacturer From China

1. For industry fields use,such as petroleum, power, papermaking, chemical, aviation, boiler heat, exchanger fields.

2. For electric, shipbuilding, construction fileds

3. For the foodstuff,medical equipment, and other fields

Packaging & Delivery of ISO2531 All Socket Tee Of Manufacturer From China

Packaging Detail: wooden cases with plastic layer, wooden pallets with plastic layer, steel crates. Or as per customer's requirements.

Delivery Detail: according to your order.

Quality Control of ISO2531 All Socket Tee Of Manufacturer From China

Our team concentrates on quality management, technique improvement and innovation, by regarding quality as the first and foremost factor in our organization development. Quality control is arranged through all stages of manufacture. We have good quality control system, great production capacity and perfect quality stability.

- Q:What about the PVC-C joint?Catgut implantation. Where are the connections of the two tubes of the casing PVC-C?!

- At one end of the pipe, apply a special glue, insert a joint, and then put the other end of the glue, and then plug into another joint, so that's fine

- Q:what ways can you masturbate?

- have the gas company leak detector dude inspect you apt. for leaks . avoid an explosion

- Q:does anyone know what the lights are called at a zebra crossing and why they are called that?

- PVC is NOT strong enough for a tricycle frame. learn to weld and go for steel or aluminum instead.

- Q:I want to stand a 9' copper column on my patio for decor. It will only be 8' from the house. i dont want it to be a lightning rod, any tips or references would be appreciated. Thanks.

- it only comes in blue, red, white, and black. try a plumbing supply store.

- Q:POLL: Is there a fire extinguisher in your home? BQ: Do you know how to use it?

- I think 14 is Frame 25 is either pixel or mega pixel i cant remember which is smaller 26 is a telephoto lens 40 is flash down 4 diffuseri think that is how it is spelled

- Q:My girl was naked in the shower and my friend Alex walked in and saw everything.Since, he won't stop staring at her boobs and butt. I think he likes her. But now he tells other people that my girlfriend showed him her pussy.I told him to stop. But, now he is sending her pics of his d*ck and she is getting uncomfortable around me now.What did I do?? I have asked and begged alex to leave her alone.It got really bad when I was fingering my girl and he walked in and videoed her.I tried to get his phone but he locked his phone.What do I do??

- I think it will only pull everything in space but not the space itself because space is nothing. And if it is nothing, how can it be pulled by a black hole? If ever space can be pulled by a black hole, then what will be left in the universe is the black hole and a blank space

- Q:I had my car sitting in the driveway for 3 months, the battery had died completely; but when I tried to start it all I heard was clicking sounds. When I had the engine replaced the mechanic said I had to pay extra to buy a tranny because the engine locked up? Im wondering how when it worked fine last time I drove it..Can someone please explain to me what it means when a engine locks up.? What causes it .? What happens to the engine?

- I had a 2000 Chrysler Town Country that I finally had to junk, it finally dropped dead. But I made it last by doing a lot of the interior repairs like this with the help of the Haynes Manual for it. There's one available for the Honda Accord as well. It should have step-by-step instructions on how to replace the lock or any of its components.

- Q:All I can find, is that they were banned in California, because of their demonstratable bioaccumulation in mammals - humans included. Based on animal studies, these chemicals have been implicated in causing thyroid problems and neuological damage. In fact, only a single dose of Pecta substantially brain damaged fetal mice in the test group.So are these two chemicals banned in the US, or not? And if so, when were they banned?I have a 2007 Ford Ranger truck, purchased in January 2007. Pecta and Octa were used in vehicle interiors, and have been discovered as contaminants in the dust inside cars, as well as in the stagnant interior air one first breathes in after a car's been sitting in the sun. Are they in my truck? Moreover, my father (see: idiot) while riding passenger in my truck, once, took his hand and swept it across the dash, deliberately disbursing a whooole lotta dust up off of it and into the air that I had no choice but to subsequently inhale. Could this be bad for me?

- Yeah, it's funny you gave all the wrong examples, all the things were made or could be made *after* these laws were passed. And of course, we became a superpower simultaneously with big unions, government wage and price controls, 92.5% top tax rate and so on. And countries like Japan may have smaller wages but they have even better health and safety standards. Same with Germany. It shows you can be an industrial leader with all these things. As we were at one time. I think the problem is if one firm enacts health regulations, then he is at a disadvantage. But if everyone is made to do it, then all firms can implement the regulations and everyone is better off. And, I think what is most important is that if all firms treat their workers well, then everyone in the long run benefits from happier employers. But then, if you trade with countries that don't have these laws, then you can lose your manufacturing jobs.

- Q:Hi,My myopia is pretty high. I wear powered goggles during swimming and I do just fine.I am thinking of taking up water polo for fun. I don't think I'll play it competitively. But I never seen a water polo player using goggles. Is there a rule against this?Just how violent is the sport of water polo? Any useful information

- Some fire alarms are linked check other alarms for smoke near them. Also they will chirp if batery is going bad but not go off for several seconds. Paint steam or fog can also set them off. I too would be woried sometimes they catch something not dangerous and sometimes its smoke you don't see.

- Q:OK I was 12 when I started wetting the bed.I just wasent once or twice it was everyday.I started wearing a diaper.I would fill it up then it would leak out .To make it worse my mom would make my sister go to the store to get daipers .She always bought boy super hero or transformer.Then should would take me to the store just to pull down my pANTS.I got rubber sheets.but it still leaked out.One time i went camping with a friend .i leaked all in the tent.I was still sleeping so my friend took a picture of me with my front wet, and my diaper completely fullCAN YOU TELL ME YOUR STORY OR SOMTHING THAT COULD HELP IM 14 WETTING THE BED HELP AM I WIERD OR A LOOSER

- Spray raid in the hole, then plug the hole with something (cork works good). Kills the bees in there, and prevents reuse of the nest. Do this at night just before it gets dark to avoid being stung.

1. Manufacturer Overview |

|

|---|---|

| Location | Liaoning, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 13 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; ISO2531:1998 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Dalian, Tianjin |

| Export Percentage | 52% |

| No.of Employees in Trade Department | 500 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b)Factory Information | |

| Factory Size: | Above 6500 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

ISO2531 All Socket Tee Of Manufacturer From China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000Pcs/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords