Stainless Steel Pipe Fittings Butt-Welding Equal Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

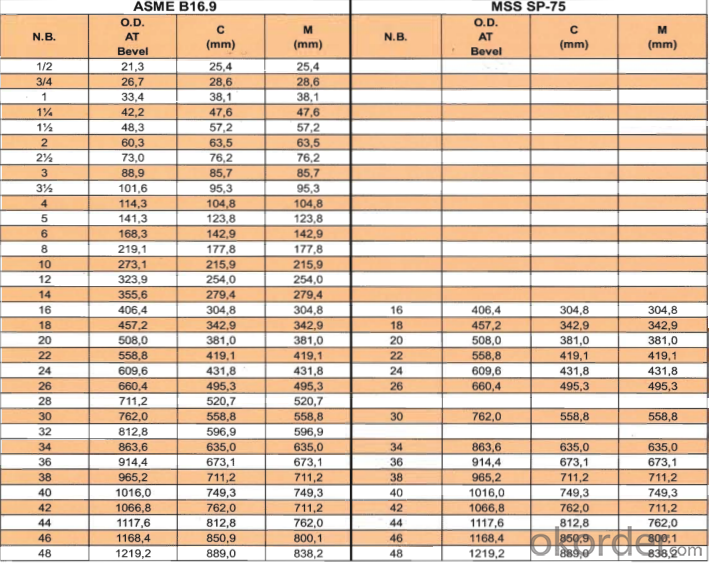

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process:

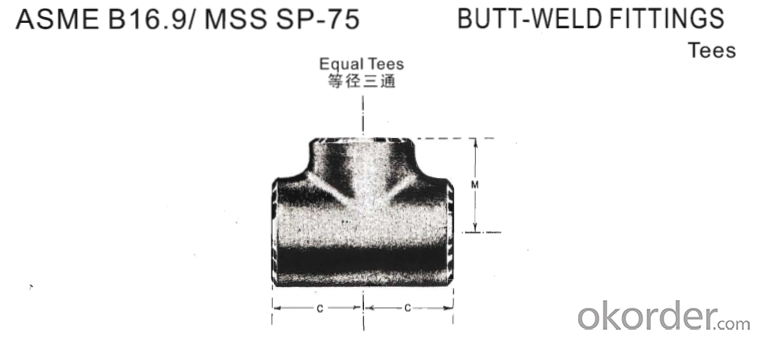

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Equal Tees:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:I already have an airsoft gun. I just would like to be able to skirmish. They think it's really dangerous and I'm going to get shot in the eye through the paintball mask I have. It doesn't make sense but, you know how they are. Any ideas on how to prove to them I can handle it?

- Personally I would have used a compression fitting myself because the brass ferrule ( the little ring) actually bites into the copper tubing and is virtually foolproof. There is more of a chance for rigid tubing stretched by flaring to have stress cracks because it isn't meant to be stretched into a flare. Having said that, as long as it doesn't leak currently you should be fine, just keep an eye out for dripping which would be the forerunner of a failure that you feared in the first place.

- Q:Why does it take so long to extinguish forest fires?

- Buy a book on basic residential plumbing and DIY it of course! I assume you're talking about drain plumbing, not supply plumbing. Basically you'd find a point at which you're confident in the drain and make a plan for replacing all the drain from the toilet to that point. Its going to involve PVC pipe, fittings, and glue, a hack saw, file, screw driver, and possibly a rubber compression sleeve. That's just for the pipe. You'll need access to the drain for the entire length which might mean cutting into drywall, flooring, etc. Provide more details and maybe some pictures for more specific advice.

- Q:What is the reason that the rubber hose of the fire hose is flowing black oil?

- This is the groove of the fire trench, the connection of the pipeline meets all the requirements and the quality is not satisfied. That is, the quality of aprons.

- Q:secure myself with a seat belt, have a car with air bags, safety glass, collapsable steering column, etc. And still pay outrageous insurance premimums, even though I have never been at fault in an accident. But people with motorcycles get to drive around with no helmets, no safety clothing requirements, loud pipes, and their insurance is nowhere near what I pay. I think their insurance should be ten times what a car owner pays. What do you think?

- There is very little you can do without that ferrule (sleeve). They are very inexpensive.

- Q:What joints do nylon hard tubes work on?

- (I) flared type pipe jointApplication: oil, water, gas and other non corrosive or corrosive medium pipe joint with steel pipe specifications and flexible pipe welding, has the characteristics of reliable connection, good sealing performance, so it is widely used in oil refining, chemical industry, light industry, textile, metallurgy, national defense, aviation, ship etc.; also suitable for hydraulic transmission of various mechanical engineering, machine tools and other equipment pipeline. Flared tube fittings are manufactured in the following six categories:

- Q:I am planning on doing a science project that involves dry ice and the fog that it creates. Will the fog set off smoke alarms? (I can t find any clear answers)

- Maybe they lived in the Montana State University-Billings dorms for a while. The fire alarms would often go off at 3 in the morning on the worst days for weather out of the year, for reasons such as a pipe froze and dripped water on the control panel or a random glitch in the system. This would sometimes happen more than once in a night. It became nearly impossible to take the fire alarm seriously. Especially considering that in the probably 15 or more fire alarm soundings they experienced during the four years I was there, NONE of them were for an actual fire! The closest thing to an actual fire was some burnt toast in the cafeteria. No actual fire, just a thin cloud of smoke and a barely perceivable black circle on the ceiling. I can't say that I really take any fire alarm seriously after that. I take notice when I start seeing smoke.

- Q:seriously, at what point do you just go ahead and wear a tinted face-shield?

- I think the best thing for you to do is to bring it to sony service centre.

- Q:cherry tree weeping its resin’ visual imagery?

- Also worth having a look on the 'Bay

- Q:The hydraulic pipe fittings how to distinguish the British, American, metric!

- Metric thread tooth angle of 60 degrees, fine teeth; British American pipe thread pitch, basically the same, but the BSP screw tooth angle is 55 degrees, American pipe thread angle is 60 degrees. The difference between the metric and inch pipe screw thread, the:

- Q:Aside from stop, drop, and roll.I need to know for a poem I am writing.Weird, yeah?

- on an analogous time as using in a set of roughly 15 on a path almost all of the horses spooked at a highway crossing whilst a cement truck glided with the aid of. distinctive riders (13 with the aid of the time it grow to be all pronounced and completed) have been given thrown and my ultimate pal have been given trampled with the aid of her horse. They airlifted her out with the aid of helicopter after medics have been given her returned to the camp. The helicopter had to land interior the exterior using section so they had to usher in hearth autos because of the prospect of sand being sucked into the engine. all of the horses in camp spooked of path and actually everyone grow to be chasing horses for hours after the helicopter left to take my pal to the well-being midsection. They considered it a severe trauma case because of the trampling and he or she swore she could no longer circulate something under her neck. So besides, she have been given released from the well-being midsection that night. Her injuries- bruised ribs and a huge hoof print formed bruise ineffective midsection on her chest.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Pipe Fittings Butt-Welding Equal Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords