Stainless Steel Centrifugal Pump Electric High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Company Introduction

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Manufacturing process:

1.Stamping of lamination

2.Rotor die-casting

3.Winding and inserting – both manual and semi-automatically

4.Vacuum varnishing

5.Machining shaft, housing, end shields, etc…

6.Rotor balancing

7.Painting – both wet paint and powder coating

8.Motor assembly

9.Packing

10.Inspecting spare parts every processing

11.100% test after each process and final test before packing

Features

1. Hydraulic design with wide flow-path non-clogged structure ,allowed fibres(3 times

length of inlet diameter),particles(30% size of inlet diameter )

2. Excellent design,high efficiency and energy saving .

3. Double mechnical seals in series,made of hard alloy corrosive proof silicon

carbide,which is durable and .wearable ,that enable pump safely operation for more

than 8000 hours continous.

4. Compact structure, small volume, easy moved and conveniently mounted , no need build

pump house, greatly reduct the cost.

pump superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

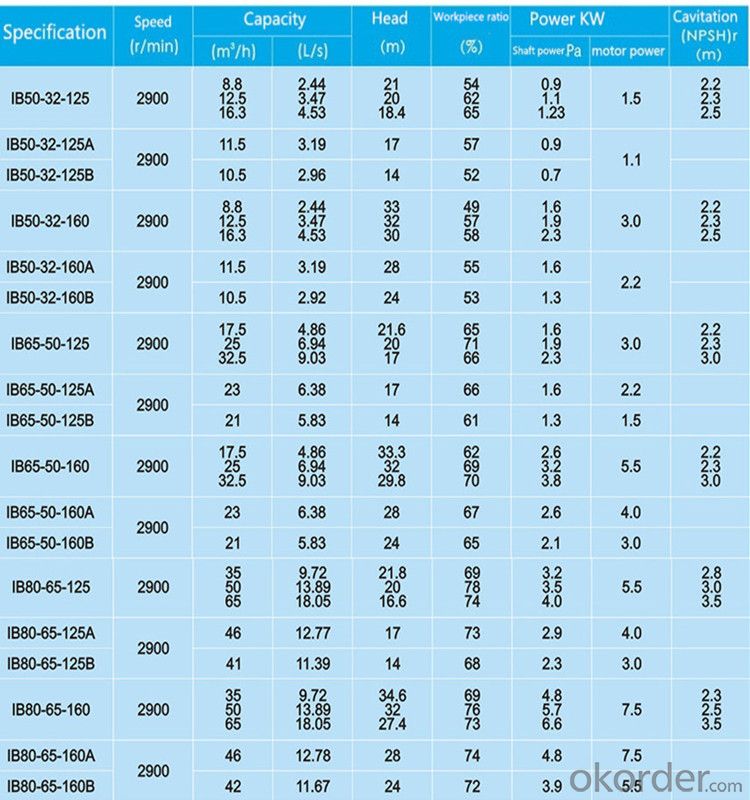

Product specification

Pictures show

Transportation

- Q:What are the commonly used tools for repairing water pumps? Mainly for civilian 220V submersible pumps, self-priming pumps. How much is the spare parts ready for use?

- The most basic tools: a multimeter only about 20 yuan, 6 - 19 wrench a set of about 20 yuan, 200MM, 600MM adjustable wrench for each one of about 40 yuan, a cross, a screw knife is about 6 yuan, about 100 yuan a Lamar, claw hammer, hammer, rubber hammer, flat shovel each one about 40 yuan, a vise, pliers, diagonal pliers pliers, 8 words for each one of about 30 yuan, tweezers, knives, pressing line plate each one of about 15 yuan, 60W electric iron to about 25 yuan, a box, a soldering flux of about 15 yuan, or lamp the incandescent lamp, the crowbar can use local materials, needle, slide board with bamboo made with wood or self winding plate with the line of 80 yuan purchase mode. Insulating paint, asbestos pipe and tie band. Commonly used spare parts: enameled wire, water resistant lines, insulating paper, lead wires, various types of seals, bearings, impellers, lithium based grease, etc..

- Q:can't get the pulleys to line up I know I have a mid 70's 400 and the water pump is later than 1969 but I can't find a pulley that works every one is about a half inch off I bought a aftermarket set of underdrive pulley's from march performance and still the same problem the water pump is a half inch off there was no long or short water pump right they are all the same lenght right??? The only difference I know of is that pre 1968 the pumps have a 8 bolt design and after they have a 11 bolt design is that right???

- Actually there was two main pumps for the older ones,, one was called a short shaft,,and one was called a long shaft,,the long shaft was the most popular,and it all depends on whether your car had power steering,,and air conditioning on it,,all the ones that used the long shaft usually had air,,and power steering on them also,,also some of them had a smog pump on them,,this was the main reason they used the long shaft,,most of the smog pumps got taken off and discarded down through the years,,but you still had to use the pump that had the long shaft,,this is the problem your having,,i own a repair shop in Tennessee,,and have been redoing some old cars in the past few years i to have run across the same problem you are having,,you can have a long shaft ordered for you ,,and it will work fine,,i had to use the long shaft on the one i was redoing hope this helps some.

- Q:It DID start after the Water Pump was put on. And i have not yet been able to detect a vacuum leak. The quot;whistling noiseseems consistent with RPMs, and the quot;dieseling(run-on) stopped in all but a rapid succession of 5 quick ~1-minute start/stops when the engine was fully warmed.. then it minorly ran-on.Could i be driving myself nuts over a Water Pump sound, and if it IS a Water Pump bearing, do i need a new Water Pump?1984 Chevy Camaro. 2.8 V6 carb'd 165,000 miles Auto.

- nicely, whilst you're like me you should make effective your self which you're turning out to be performed what ought to be performed. So, to locate precisely the place the noise is coming from, get your self a stethoscope. we are going to use component of backyard hose for this and it artwork great, 3-4 feet long. place one end on your ear and flow the different end around the engine (being careful of all shifting areas) the place you think of the noise is coming from. this variety you would be waiting to pinpoint the place the noise is and what section is making it. you would be attentive to you have discovered it whilst the noise is loudest. get rid of and replace. attempt this and that i assure you will locate the priority. you will be able to choose help revving the engine at those rpm you indicated. sturdy success!

- Q:OK i was driving and i noticed the gas pedal wouldn't really work and people were telling me to move so right away i moved to the side of the road and got my car towed home. a couple details are that there was smoke coming out of the hood, don't know what part of the engine though.there was not much water in the water pump. my dad thinks that the problem was it was leaking the water.the car turns on ac works it just shakes when it turn on the motor no condition to drive it obviously but it does take a little time to start the engine. i want to know if anyone knows what may be the problem and about how much it may cost.ohh btw this car model is a 1999 Chrysler Sebring Convertible 2 door.thank you!

- fill radiator and then start the car. Look for any leaking. Check radiator and all hoses as well as the waterpump. also look at both heads. Still if not then do the following. Watch the radiator cap. If the steam is coming out of the cap then replace it $6. If it still goes out cap then replace the thermostat. If there is no water signs then the head gasket needs replaced

- Q:Is the pump head related to the water level of the entrance and outlet? If the water level of the inlet and outlet is on the same level, but higher than the height of the pump, does the pump lift need to be coupled with this height difference?

- What's the relationship?! When the inlet level is low, the head is slightly higher than the liquid level!

- Q:water pump has small leak

- Realistcally you have a 10 12 months previous motor vehicle, so your water pump has used up its existence sorry. provide up leak products are in lots of situations an outstanding powdered aluminum/epoxy combination and NO they gained't fix a water pump seal. previous provide up leak products have been easily extra suitable yet used asbestos as a leak fix, so the government banned its use. My advice, is to save around slightly for yet another value, because it does sound incredibly steep. Sorry approximately your concern. Please remember anti freeze can bypass on the instant, so do no longer threat an engine overheat at a foul time, carry 2 gallons of spare coolant

- Q:I recently changed the lower unit, and am having no water out the top 2 ports just below the powerhead, also the engine is getting heated up. any other pumps other than in the lower unit?any advice is appreciated.

- Both jtexas and mrfixit are experienced mechanics and know their stuff. The exhaust by-pass which your describing as 2 holes, only get a mist of water, most of it comes out at the bottom of the drive. Depending on model it comes out the center of the prop, or through the skeg-fin. The power head should get warm, but not hot enough to cause water to sizzle when you sprinkle some on the heads. Most common problem, is blockage at the top of the water tube, or the thermostat isn't opening. But if your running on a flush attachment, check the water that's coming out at the exhaust area, it should be warm. I hope this helps! Good luck!

- Q:How do I change the water pump on a 2003 PT Cruiser. What do you do with the timing belt and gears?

- if you have 100,000 miles on it, and haven't changed the timing belt, CHANGE IT NOW. Recommended change at 100,000 miles. Mine broke at 104,000, towing was $125, and then cost of repairs. Also recommend changing seals on xmission at same time.

- Q:For a Dodge Ram 1500 pick-up. Not taking it to a mechanic.Already got the new pump. Got part of the engine off.Dont exactly have the right tools to make the job go fast but would like some tips on how to make it go faster..

- If you've got the fan off you have the hardest part done on that vehicle,follow the manuals and line the parts up as you remove them.Be sure to put the bolts with the part they belong to and install them in the reverse order you took them off.

- Q:I want to buy a 2000 Audi tt coupe that seems to be in good condition. The owner mentioned he has replaced the water pump. What could the reason be for having to replace the water pump? Could the car have over heating issues?

- IT is EXPECTED that you replace the WATER PUMP and TIMING belt at 100k mile INTERVALS on ALL audi cars! The KIT is about $250 from CONTINENTAL using a HEPU water pump! It is ALSO NORMAL to FLUSH And FILL ALL FLUIDS at 100k mile intervals as well, even the BRAKE and STEERING FLUIDS! Consult with BLAUFERGNUGEN and 1-800-ALL-AUDI and 1-800-ALL-EURO. ALL small engines with TIMING BELTS require PUMP and BELT changes at 100k mile intervals! The AUDI has BOTH a timing chain AND a timing belt! AUDI REQUIRES THAT SPECIAL SYNTHETIC OIL that is EUROPEAN with the numbers 502/505 PRINTED ONTHE AALBEL! NO VALVOLINE may be used in ANY EUROEAN CAR! GOOD LUCK!!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Centrifugal Pump Electric High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords