Split Casing Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Split Casing Water Pump for Farm Irrigation

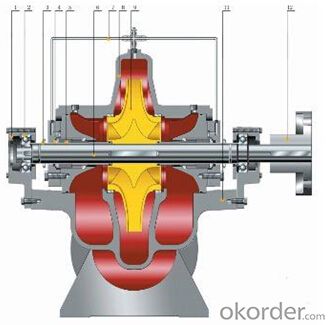

1.Split Casing Water Pump for Farm Irrigation Description

The Single Stage Double Suction Split Casing Centrifugal Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Split Casing Water Pump for Farm Irrigation

•Attractive design

•High efficiency, steady performance

•Big capacity, medium pressure

•High concentricity of components

3.Split Casing Water Pump for Farm Irrigation Specification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

4.Picture of Split Casing Water Pump for Farm Irrigation

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q:Mercedes 2000 ml 320. I changed radiator and water pump now car only runs half as worm than it used to. So now heat blows cold to little warm depending on how cold out side

- Definitely check your thermostat out...

- Q:What are the commonly used tools for repairing water pumps? Mainly for civilian 220V submersible pumps, self-priming pumps. How much is the spare parts ready for use?

- This universal table is necessary, there is an insulation resistance meter, with some 8 six angle screws, as well as a common pump mechanical seal, you can also enter some of the water pump cable

- Q:What does the pump lift mean?

- The pump head is the height or length of the distance from the pump to the outlet

- Q:I have a 1999 Chevy Cavalier Z24 2.4 engine and the water pump needs replaced how much would this cost me to take to a garage to have fixed?

- good okorder and see what is up with the price. The estimator sectrion may be able to give some idea of what a water pump sells for and the labor costs. One major problem with all of the front engine front wheel drive cars is the cost of replacing a water pump can be 2 to 4 times as much in labor as the front engine rear wheel drive vehicles of the 70a and 80s for example my suburban was a total of 200 dollars not so with the cavalier The water pump itself was not too bad but the labor getting to it sucks. 104 to 199 dollars for a waterpump and 627 to 800 dollars for the labor could bring you a bill for 732 to 999 dollars lets hope its the cheaper of the estimates

- Q:What is called soft start of water pump?

- Soft start has many methods, mainly used in high-power motor.Through soft starter, or frequency conversion start, or star triangle start to achieve.It means that it starts at a slower pace.

- Q:I'm looking to buy a used 2001 Protege. The car is nearing 75000mi, but the owner has not changed the timing belt or the water pump. I found out that it is recommended to change the timing belt at 60000mi, but couldn't find anything on the water pump. Realistically, when would I need to replace these, and any idea how much it would cost?Thanks!

- That could have either the 1.6 liter or 2.0 liter engine. My information shows that if you have the 1.6 liter, at least you don't have to worry about bending valves against pistons if the belt breaks -- you'll just be stuck out on the road until you can get it towed and fixed. Not so with the 2.0 which is an interference engine. So if you DO have the 2.0, pay attention -- you don't want an expensive breakdown! You're on borrowed time at 75K. For both engines, Mazda recommends that you replace the timing belt every 60K miles. Gates (a major replacement supplier) seems to think these belts will go 105K. Since it's a factory belt, stick with 60K. As for the water pump, it's often one of those while you're already in there sort of things when you're doing a timing belt. 60K makes it a tougher call, especially with the better quality of water pump bearings and seals. If your interval were 80K ~ 100K as is true on some cars, I'd say go for it without blinking. As cheap as it'll be (it's really just the price of the pump), and it was my set of wheels, I'd do it anyway, even at 60K, if it needed to be pulled to do the belt.

- Q:Pump frequent start will reduce the service life, I ask what kind of frequency is called frequent start?

- Personally think that the quality of different motors have different effects on the motor, you can try, try a minute it ruined his frequency is a / S

- Q:Ok, so I was driving the other day when I heard this quot;clunksound...my AC went out (stopped blowing cold), and power steering went out. I pulled over and one of the wheels where the serpentine belt goes on was off and obviously the belt was off too. I got it towed to a shop where they showed me I needed a new belt - it was ripped, and told me I need a new water pump...all together a 400 dollar job after labor and parts. I was hoping I would just need a new belt and they could bolt back on the wheel...From a chic standpoint, this seemed logical. I know nothing about cars and I'm always very skeptical when I take my car anywhere to get it worked on bc I could be told anything and wouldn't know the difference...Has anyone had a similar experience or does this sound like the problem? I have a 07 honda civic...around 80,000 miles.

- 400 okorder and the water pump replacement was 273 to 322 dollars. I could not find a price for the water pump belt and the tension-er pulley that is usually replaced then too but piece wise I think the shop is not trying to hose you. Its always good to pay attention however. anytime you lose a belt like that, shut off the car it can overheat quickly and blow a head gasket or worse the motor. Some people just do not understand that when a catastrophic failure occurs and you lose several important functions all at once park the car until it gets fixed. Repairpal takes a bit of getting used to when first trying out, but it can give you some price guides that are right on the money when you are not sure what the mechanics are telling you. good luck pay attention.

- Q:Looking for a pro's advice here. My Corolla has developed a strange noise over the past few cold weeks (Highs of 10 degrees max, well below zero at night). The sound would best be described as a cricket-type rythmic chirp noticable during acceleration. I don't believe it's a belt because it comes and goes though it has steadily gotten louder. I vaguely remember this sound being related to a bad water pump I had a few years ago. Do you think this could be the same thing? Three years for a water pump? And do water pumps tend to go out more frequently in the cold weather? Thanks!!!

- timing belt

- Q:hi, how long does the water pump last on e65 chassi 745i (miles)

- Usually car manufacturers estimate that most car parts (like a water pump) would last the warranty period and this means 40k to 50k miles. Original water pumps from dealers which are installed during car repairs are usually warrantied for 2 years. Of course this can be voided by driver abuse such as overheating the car or low coolant level.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Split Casing Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords