Refractory High Alumina Thermal Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

65% Al2O3 Min High Alumina Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

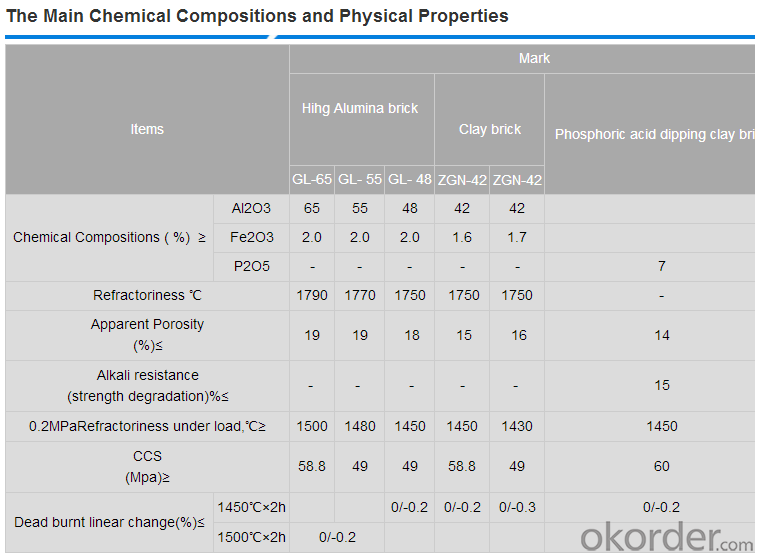

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

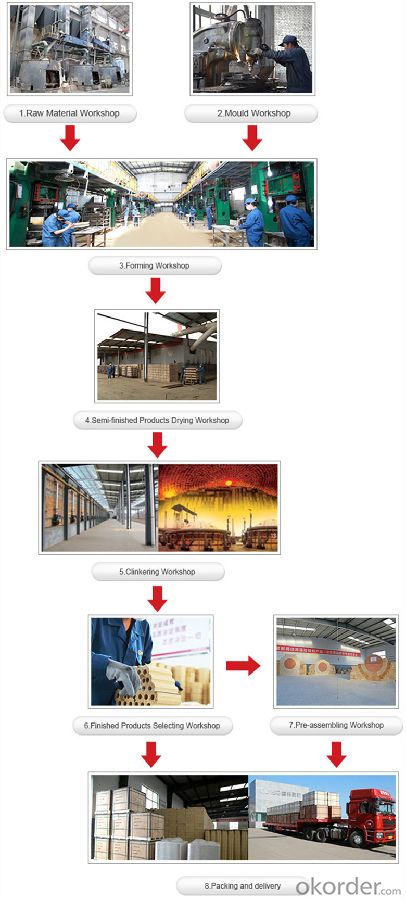

Produce Processing

- Q:Can insulating fire bricks be used in the construction of hot blast stoves?

- Yes, insulating fire bricks can be used in the construction of hot blast stoves. Insulating fire bricks are designed to have low thermal conductivity, making them effective at reducing heat loss. Hot blast stoves require high temperatures to be maintained for efficient operation, and insulating fire bricks can help in achieving this by minimizing heat transfer to the outer surface of the stove. These bricks also have good insulation properties, which help to conserve energy and improve the overall efficiency of the stove. Additionally, insulating fire bricks are resistant to thermal shock, which is important in hot blast stove applications where frequent temperature fluctuations occur.

- Q:Do insulating fire bricks have a high thermal stability?

- Yes, insulating fire bricks have a high thermal stability. These bricks are designed to withstand high temperatures without deteriorating or losing their insulating properties. They are made from high-quality refractory materials that can withstand extreme temperatures, making them ideal for applications where thermal stability is crucial. Insulating fire bricks have low thermal conductivity, which means they can effectively trap heat and prevent it from escaping. This property allows them to maintain stable temperatures in environments where heat retention is essential, such as furnaces, kilns, and other high-temperature industrial processes. Overall, insulating fire bricks are known for their excellent thermal stability, making them a reliable choice for applications that require insulation and protection against high temperatures.

- Q:Are insulating fire bricks fireproof?

- Yes, insulating fire bricks are fireproof. They are designed to withstand high temperatures and provide insulation to prevent heat transfer. Insulating fire bricks are made from refractory materials that have a high melting point and can withstand extreme heat without melting or crumbling. They are commonly used in applications where high temperatures are present, such as kilns, furnaces, fireplaces, and ovens. Insulating fire bricks are an excellent choice for fireproofing as they offer excellent thermal insulation properties and can effectively protect against the spread of fire.

- Q:Can insulating fire bricks be cut or shaped as needed?

- It is possible to cut or shape insulating fire bricks according to one's needs. These bricks are manufactured using lightweight materials like ceramic fibers and refractory materials, which make them more easily cut and shaped compared to traditional dense fire bricks. Cutting them can be done effortlessly using a saw or a specialized cutting tool, while shaping can be achieved through grinding, sanding, or chiseling. The ability to cut and shape them gives the advantage of custom fitting the insulating fire bricks to specific applications or structures. However, it is crucial to emphasize that precautions must be taken for safety while cutting or shaping the bricks. Wearing protective goggles, gloves, and a dust mask is essential in order to prevent inhaling any hazardous particles.

- Q:Can insulating fire bricks be used for insulation in cement kilns?

- Insulation in cement kilns can be achieved by using insulating fire bricks. These bricks are made from lightweight materials like ceramic fibers or expanded clay, which possess high insulation properties. Their low thermal conductivity allows them to effectively reduce heat transfer and retain heat within the kiln. Cement kilns operate at extremely high temperatures, often surpassing 1,400 degrees Celsius (2,500 degrees Fahrenheit). Incorporating insulating fire bricks in the kiln helps prevent heat loss, enhances energy efficiency, and reduces fuel consumption. By creating a barrier between the hot gases inside the kiln and the surrounding environment, these bricks minimize heat escape. Additionally, insulating fire bricks exhibit remarkable resistance to thermal shocks, enabling them to withstand the severe temperature fluctuations that occur in cement kilns. This durability ensures long-lasting insulation, minimizing the need for frequent maintenance and replacement. Nevertheless, it is crucial to note that the specific type and composition of insulating fire bricks required for cement kiln insulation may vary depending on factors such as the kiln's design and operating conditions. Consulting with experts or manufacturers specializing in refractory materials is advisable to ensure the correct selection and installation of insulating fire bricks for cement kiln insulation.

- Q:Can insulating fire bricks be used in gasifiers?

- Yes, insulating fire bricks can be used in gasifiers. Gasifiers are devices that convert organic or fossil fuel materials into a combustible gas called syngas. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. This makes them suitable for use in gasifiers, where temperatures can reach several hundred degrees Celsius. Insulating fire bricks help to retain heat and prevent it from escaping, improving the efficiency of the gasifier. They also offer good resistance to thermal shock, which is important in gasifier applications where rapid temperature changes can occur. Overall, insulating fire bricks are a reliable and effective choice for use in gasifiers.

- Q:Can insulating fire bricks be used in refractory fibers?

- No, insulating fire bricks cannot be used in refractory fibers. Insulating fire bricks are a type of refractory material made from ceramic fibers and are used for thermal insulation, while refractory fibers are made from different materials such as alumina, silica, or zirconia and are used for high-temperature applications.

- Q:How long do insulating fire bricks last?

- Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties. The lifespan of insulating fire bricks can vary depending on several factors such as the quality of the bricks, the temperature they are exposed to, and how well they are maintained. Generally, insulating fire bricks can last for several years, often ranging from 10 to 20 years or even longer. However, it is important to note that the lifespan can be significantly reduced if the bricks are exposed to extreme temperatures or thermal shock on a regular basis. Regular maintenance and proper usage can also extend the lifespan of insulating fire bricks. This includes regular cleaning to remove any debris or build-up that can impact their performance. It is also important to avoid sudden temperature changes or excessive stress on the bricks, as this can lead to cracking or damage. Overall, the longevity of insulating fire bricks can vary, but with proper care and maintenance, they can provide reliable insulation for many years in high-temperature applications.

- Q:Are insulating fire bricks resistant to cracking?

- Yes, insulating fire bricks are designed to be highly resistant to cracking. They are manufactured to withstand high temperatures and thermal shocks, ensuring their durability and preventing cracks from developing.

- Q:What is the typical density of an insulating fire brick?

- The specific composition and manufacturing process of an insulating fire brick can cause its typical density to vary. In comparison to regular fire bricks, insulating fire bricks generally possess a lower density. Their density typically falls within the range of 0.8 g/cm³ to 1.2 g/cm³. To attain this lower density, insulating materials such as lightweight aggregates or organic fibers are incorporated into the composition of the brick. This incorporation serves to diminish heat transfer and enhance the brick's thermal insulation properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory High Alumina Thermal Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords