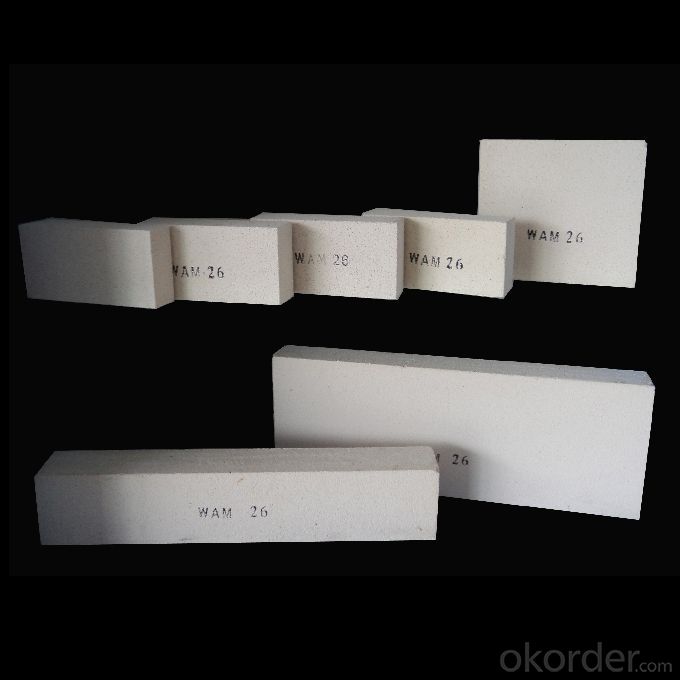

Refractory Mullite Insulating Fire Brick GJM23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q:Can insulating fire bricks be used in ladles?

- Yes, insulating fire bricks can be used in ladles. Insulating fire bricks are designed to withstand high temperatures and provide thermal insulation. They are commonly used in applications where there is a need to maintain or control high temperatures, such as in furnaces, kilns, and ladles. Ladles are used for pouring and transferring molten metal or other materials, and the use of insulating fire bricks in ladles helps to minimize heat loss and improve energy efficiency. Additionally, insulating fire bricks can also provide a protective barrier against chemical reactions and erosion caused by the molten materials, making them suitable for ladle applications.

- Q:Can insulating fire bricks be used for insulation in sewage treatment plants?

- Insulating fire bricks are capable of being utilized for insulation purposes in sewage treatment plants. Specifically designed to endure elevated temperatures and deliver exceptional insulation, these bricks prove to be suitable for deployment in environments characterized by heat and moisture, such as sewage treatment plants. With their low thermal conductivity, they aid in diminishing heat loss and enhancing energy efficiency throughout the treatment procedure. Furthermore, their resistance to chemicals and moisture renders them ideal for enduring the corrosive surroundings typically encountered in sewage treatment plants. Consequently, the usage of insulating fire bricks effectively ensures insulation in sewage treatment plants, thereby aiding in the preservation of optimal operating temperatures and the enhancement of overall efficiency.

- Q:Are insulating fire bricks eco-friendly?

- To some extent, insulating fire bricks can be considered environmentally friendly. These bricks are typically crafted from abundant natural materials like clay, shale, and other fire-resistant minerals. The manufacturing process involves firing the bricks at high temperatures, which can consume a lot of energy. However, advancements in manufacturing techniques have mitigated the environmental impact by using more efficient kilns and recycled materials. Furthermore, insulating fire bricks boast a long lifespan and can endure high temperatures. This means they require less frequent replacement compared to other brick types, resulting in reduced waste generation and resource consumption over time. Moreover, these bricks possess exceptional thermal insulation properties, which can contribute to decreased energy consumption in various applications. By minimizing heat loss, insulating fire bricks can enhance energy efficiency and reduce carbon emissions in both buildings and industrial processes. Nevertheless, it is crucial to note that the eco-friendliness of insulating fire bricks also hinges on their proper disposal at the end of their life cycle. If not recycled or disposed of appropriately, they can contribute to landfill waste and potential environmental pollution. In conclusion, while insulating fire bricks offer certain environmentally friendly features, such as being made from natural materials and their energy-saving properties, their overall environmental impact also depends on responsible manufacturing, usage, and disposal practices.

- Q:Are insulating fire bricks resistant to corrosion?

- Yes, insulating fire bricks are resistant to corrosion.

- Q:Can insulating fire bricks be used in metal smelting furnaces?

- Yes, insulating fire bricks can be used in metal smelting furnaces. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in furnaces where metal smelting occurs. They help maintain consistent heat levels and reduce heat loss, allowing for efficient and effective metal smelting processes.

- Q:Can insulating fire bricks be used in the construction of reheat furnaces?

- Yes, insulating fire bricks can be used in the construction of reheat furnaces. These bricks are designed to have high insulating properties, which helps to minimize heat loss and improve energy efficiency in the furnace. Additionally, their lightweight nature makes them easier to handle and install.

- Q:Can insulating fire bricks be used in the construction of hot air generators?

- Indeed, the utilization of insulating fire bricks is applicable in the fabrication of hot air generators. Specifically engineered to endure extreme temperatures and deliver exceptional thermal insulation, insulating fire bricks are well-suited for incorporation into hot air generators. These generators necessitate insulation to uphold elevated temperatures and avert heat dissipation. By diminishing heat transfer to the surroundings, insulating fire bricks effectively enhance the efficiency and functionality of hot air generators. Furthermore, their lightweight nature, effortless installation, and long-lasting durability contribute to their widespread adoption in diverse industrial sectors, including the construction of hot air generators.

- Q:Is it necessary to abolish the technical regulations for the construction of self thermal insulation masonry building with sludge sintering insulation bricks?

- Silt sintering brick insulation brick is made from river mud, city sludge, mud as the main raw materials, added according to a certain proportion of siliceous inorganic binder after aging, extrusion blank, blank by cutting, drying, sintering and extrusion molding machine. The utility model has the advantages of energy saving, resource saving, favorable for developing circular economy and comprehensive utilization of resources, high micropore rate, good product heat insulation performance and heat insulation performance, etc..

- Q:Can insulating fire bricks be used in the construction of ceramic fiber-lined kilns?

- Yes, insulating fire bricks can be used in the construction of ceramic fiber-lined kilns. Insulating fire bricks are specifically designed to provide high levels of insulation, making them ideal for applications where heat retention is important. When used in conjunction with ceramic fiber lining, insulating fire bricks can help increase energy efficiency and reduce heat loss in kilns. Additionally, insulating fire bricks are lightweight and easy to work with, allowing for easier installation and construction of the kiln. Overall, using insulating fire bricks in the construction of ceramic fiber-lined kilns can help improve the kiln's performance and efficiency.

- Q:What is the price of concrete self insulation bricks?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Mullite Insulating Fire Brick GJM23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords