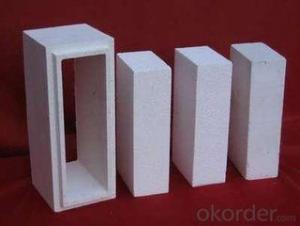

Refractories Fireproof Mullite Insulating Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Mullite insulating brick kiln bricks for sale

Product Description

Description:

Lightweight mullite refractory bricks are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:

The refractory linings of hot surfaces or backing heat-insulating layers of other refractory materials. The refractory linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns,etc

Sunrise Brand | JM23 | JM26 | JM28 | JM30 | JM32 | |

USA Brand | IFB2300 | IFB2600 | IFB2800 | IFB3000 | IFB3200 | |

Classification Temperature (°C) | 1260 | 1430 | 1540 | 1650 | 1760 | |

Bulk Density (g/cm3) | 0.55-0.60 | 0.78 | 0.88 | 1.03 | 1.25 | |

Cold Crushing Strength (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

Reheating Linear Change (%) | 1230°C | 1400°C | 1510°C | 1620°C | 1730°C | |

CT-30 °CX 8H | -0.5 | -0.5 | -0.5 | -0.9 | -0.9 | |

Thermal Expansion | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

1000°C(%) | ||||||

Thermal conductivity(W/m.k) | 400°C | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

Thermal conductivity(W/m.k) | 400°C | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

600°C | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

800°C | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

1000°C | 0.2 | 0.33 | 0.38 | 0.45 | 0.53 | |

Al2O3 (%) | 37 | 58 | 67 | 73 | 77 | |

Fe2O3 (%) | 1 | 1 | 1 | 0.5 | 0.4 | |

Mullite Insulation Brick can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

- Q:What is the price of refractory bricks?

- The refractory insulating brick generally refers to light brick, normal furnace lining are using this brick kiln will not increase the weight, and good heat insulation effect and ordinary insulating brick production are made of clay, high alumina high strength low iron bead brick, mullite, high aluminum light insulating firebrick, diatomite insulating refractory brick, the use of light heat insulation brick can increase the use of space, and good insulation effect

- Q:The introduction of mullite brick

- General alumina content in 65% ~ 75% between. In addition to mullite, the mineral composition contains lower amounts of glass phase and square quartz, and alumina containing a small amount of corundum.

- Q:What is the difference between mullite ceramics and alumina ceramics? Can you tell me something to do with floor tiles?

- Mullite is formed by the reaction of alumina with silica. The main difference between him and alumina is that:Hardness: alumina is harder than mullite, but two are tough enough, and are not easy to break.Corrosion resistance: mullite acid is not alkali resistant. Alpha alumina ceramic acid, alkali resistance - for floor tiles, alumina corrosion resistance is too high, unnecessary.

- Q:The difference between the high aluminum corundum brick and corundum mullite brick

- Tiles are called floor tiles, floor tiles, polished tiles and glazed tiles are glazed tiles, bricks are samples of all kinds of tiles, ceramic tiles will be placed in the tile shop, tiles are also divided into outer wall tiles and inner wall tiles, modern brick and antique brick

- Q:What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity.

- Q:(refractory castable, silicon carbide brick, mullite bricks etc.) do testing should be commissioned by the project? What are the specific qualification standards? Thank you

- Compressive strength, volume density, flexural strength, thermal shock resistance, high temperature load, creep temperature, refractoriness, etc.. There should be GB

- Q:Mullite bricks in alumina alumina is what?

- Mullite (3Al2O3 - 2SiO2) high alumina refractory materials as the main crystal phase. The general alumina content in 65% ~ 75%. In addition to mineral composition of mullite, alumina containing low also contain a small amount of glass phase and cristobalite; alumina containing high also contain a small amount of corundum. Highrefractoriness, up to over 1790 DEG C 1600. Load softening start temperature to 1700 DEG C. Compressive strength at room temperature is 70 ~ 260MPa.. The thermal shock resistance of sintered mullite and fused mullite brick two. Sintered mullite brick with high bauxite clinker as the main raw material, adding a small amount of clay or alum clay as binder, forming and sintering made of fused mullite bricks with high alumina and bauxite, refractory clay as raw material, adding charcoal or coke fines as a reducing agent, formed by reduction of electric melting method to manufacture. The crystallization of fused mullite than sintered mullite, thermal resistance Shock resistance than sintered products. The uniformity of content in alumina mainly depends on their high temperature properties and mullite phase and glass distribution. Mainly used in blast furnace, furnace top and bottom furnace, glass furnace regenerator, sintering kiln, petroleum cracking system dead lining.

- Q:Mullite brick

- High alumina refractory with crystalline mullite (3Al2O3, 2SiO2) as the main crystal phase. General alumina content in 65% ~ 75% between. In addition to mullite, the mineral composition contains lower amounts of glass phase and square quartz, and alumina containing a small amount of corundum.

- Q:What are the varieties of polycrystalline mullite?

- PNF-100 seriesThe PNF-100 series are made of polycrystalline mullite fiber cotton felt to cut, compress, and wrap into blocks without any adhesive.Characteristic: thermal shock resistancelow thermal conductivityLight weightSound absorption propertyLow thermal storage

- Q:Refractory bricks (mullite bricks) can be used on the walls of buildings?

- Refractory bricks used in the firewall, the first choice of national standard model, its size is 230mmx114mmx65mm, model T-3, component 3.5-3.7kg, and sometimes will use refractory bricks, seven separately to make up for the effect. Refractory brick in masonry usually fireclay, refractory soil adhesion is very strong, and has a certain degree of refractory refractory, so was widely used in refractory masonry, in building fire protection requirements if the fire rating is high, to the selection of refractory masonry cement, refractory cement refractoriness of fireclay than about 500 DEG C high.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractories Fireproof Mullite Insulating Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords