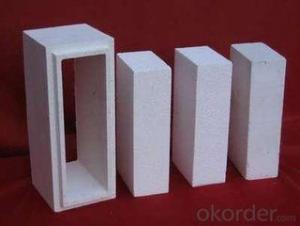

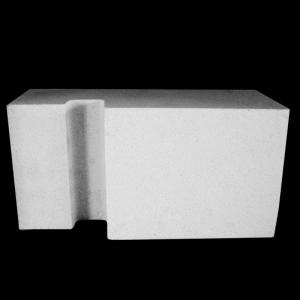

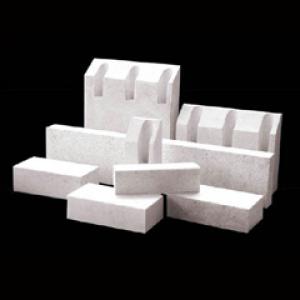

Corundum-mullite brick- Corundum- mullite ladrillos

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Corundum mullite brick technology parameters

| ITEM | UNIT | Mullite brick | Resintering fused mullite bricks | Mullite - corundum brick | Corundum mullite brick |

| Al2O3 | % | ≥70 | ≥75 | ≥80 | ≥90 |

| SiO2 | % | ≤25 | ≤23 | ≤18 | ≤8 |

| Fe2O3 | % | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.3 |

| APP | % | ≤17 | ≤14 | ≤19 | ≤18 |

| Bulk density | g/cm | ≥2.55 | ≥2.65 | ≥2.70 | ≥2.90 |

| Room temperature compressive strength | MPa | ≥90 | ≥100 | ≥80 | ≥100 |

| Dutch soft starting point (0.2 MPa, 0.6%) | ℃ | ≥1630 | ≥1700 | ≥1650 | ≥1700 |

| Application | Glass furnace upper structure brick, feeding, cover plate, metallurgy is very warm in it industry kiln lining, carbon black reactor quench section, stay segment lining. | Glass furnace top self-closed, self-closed feet, other industrial thermal technology equipment lining brick. | Glass furnace brick of upper structure, cover plate, forming parts, temperature, carbon black in the reactor and other thermal lining device.High temperature with mullite and corundum saggar. | The upper structure of glass furnace brick, brick, cover plate, molding parts, temperature, carbon black in the reactor lining device and other thermal lining.High temperature with corundum - mullite saggar. |

- Q:What material is good for refractory bricks?

- The mineral composition of high alumina refractory brick and high alumina refractory brick is corundum, mullite and glass phase. The raw materials are high alumina and sillimanite natural ore. They are also made of fused alumina, sintered alumina, synthetic mullite and calcined alumina in different proportions with clay. It is produced by sintering process. But the products are casting brick, brick, brick fused grain and unshaped refractory brick. High alumina refractory brick is widely used in iron and steel industry, non-ferrous metal industry and other industries.

- Q:Corrosion mechanism of iron on refractory materials

- Iron oxide can not be used as refractory,

- Q:What kind of refractory material is used in the hearth of reverberatory furnace?

- The alumina fiber has a maximum resistance of 1700 degrees, and the zirconium fiber is generally 1700 to 2200 degrees

- Q:What material is heat insulated and not afraid of fire?

- Foam as a kind of important organic insulation materials, there are two kinds of polystyrene and polyurethane foam, which was published in 30s, the production in our country began in late 50s and 60s, which is characterized by the effect of thermal insulation performance, light weight, sound absorption properties, but the organic materials and brick wall with construction is difficult. Need the polystyrene foam plate is adhered in the walls with special binder and coupling agent, after a plurality of process, the construction is very complex. Moreover, foam plastic products have poor aging resistance, low service life, and waste materials can not degrade and cause white pollution.

- Q:What are the high temperature insulation materials?

- If there is atmosphere protection, then graphite is a more powerful material. Melting point 3850 degrees Oh, almost all ultra high temperature kiln, can be protected by atmosphere, all with graphite material.

- Q:Mullite bricks in alumina alumina is what?

- Mullite (3Al2O3 - 2SiO2) high alumina refractory materials as the main crystal phase. The general alumina content in 65% ~ 75%. In addition to mineral composition of mullite, alumina containing low also contain a small amount of glass phase and cristobalite; alumina containing high also contain a small amount of corundum. Highrefractoriness, up to over 1790 DEG C 1600. Load softening start temperature to 1700 DEG C. Compressive strength at room temperature is 70 ~ 260MPa.. The thermal shock resistance of sintered mullite and fused mullite brick two. Sintered mullite brick with high bauxite clinker as the main raw material, adding a small amount of clay or alum clay as binder, forming and sintering made of fused mullite bricks with high alumina and bauxite, refractory clay as raw material, adding charcoal or coke fines as a reducing agent, formed by reduction of electric melting method to manufacture. The crystallization of fused mullite than sintered mullite, thermal resistance Shock resistance than sintered products. The uniformity of content in alumina mainly depends on their high temperature properties and mullite phase and glass distribution. Mainly used in blast furnace, furnace top and bottom furnace, glass furnace regenerator, sintering kiln, petroleum cracking system dead lining.

- Q:Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color. For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more

- Q:What are the properties of corundum mullite?

- Heavy material has good compactness, high compressive strength, resistance to various corrosive gases, good thermal shock resistance, good thermal conductivity and wear resistance.

- Q:2000 degree of high temperature materials, which belong to high temperature insulation materials?

- Magnesium compounds, ceramics, mica, corundum, silicon, graphite, titanium alloy, diamond, tungsten, silicon dioxide, silicon carbide, carbon, copper oxide, iron oxide, iron, manganese, lightweight mullite corundum brick, high aluminum brick lightweight clay brick, alumina hollow ball1) rock wool board: thermal conductivity 0.041-0.045, fire retardant, fire resistance, temperature absorption, insulation effect is poor.(2) glass wool: construction is simple, free cutting. Antibacterial, mildew proof, aging resistance, corrosion resistance, and guarantee the healthy environment. Low hygroscopicity and stable physical properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corundum-mullite brick- Corundum- mullite ladrillos

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords