Profesisonal Carbon Fiber Tube/Rod/Plate Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description for Carbon fiber color tube:

1. Specification: is produced as customer's requirement.

2. Property: good looking, light weight and high rigidity

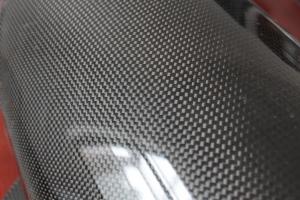

3. The outside surface:

1) one is with patterns (For example 3k plain woven patterns)

2 )the other is not

4. Color: many colors for your choice

5. Finish: glossy finish or matte finish

6. Application: to make Stationery and Sport Goods (including pens, golf poles, badminton poles, model plane tail tube and telescope tube), medical and mechanical equipment.

2. Fetures for Carbon Fiber Tube

Light Weight - Less Density - 20% Of Steel

High Strength

High Corrosion Resistance

Superior Dimensional Stability

Wide Temperature Range Use

Consistent Cross Section

Lasting Performance

Excellent Structural Properties

Environmentally Safe

Dimensional Stability

Non-Magnetic Electromagnetic

Ease Of Fabrication & Installation

3. Specifications for Carbon Fiber Tube

Description of goods |

Material |

Working process | Specification ID x OD(mm) |

below is the regular size we make, we can make customer design | |||

carbon fiber tube | 3k plain woven carbon fiber |

winding process | φ7 x φ8 |

φ8 x φ10 | |||

φ10 x φ12 | |||

φ11 x φ17 | |||

φ12 x φ15 | |||

3k twill woven carbon fiber | φ13 x φ16 | ||

φ14 x φ16 | |||

φ15 x φ17 | |||

φ17 x φ19 | |||

φ18 x φ20 | |||

φ19 x φ22 | |||

special woven carbon fiber | φ22.4 x φ25.4 | ||

φ27 x φ30 | |||

φ28 x φ30 | |||

φ29x φ35 | |||

UD carbon fiber | φ30 x φ36 | ||

φ88 x φ91 | |||

φ232 x φ236 | |||

φ300 x φ304 |

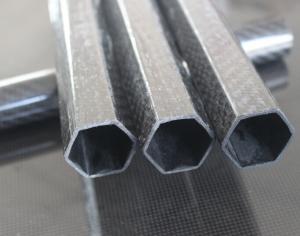

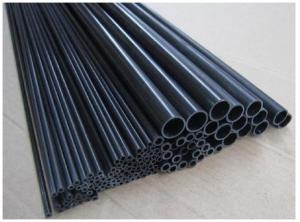

4. Photos for Carbon Fiber Tube

- Q:A boulder became dislodged in the middle of the road, right at the entrance. Instead of removing it, they put caution tape around it. It was in a blind spot and I hit it at night when the tape was not visible. They are saying they aren t responsible. I can only file small claims if I have already spent the money to fix it and I do not have $3,000 to spend on this. What are my options? (I live in WA State)

- The question is not clear. Can you give a detailed example?

- Q:poll what is something you are always prepared for?

- is there a fashion you're able to try this like for effective? cuz my college has facebook blocked, and whilst im in workplace tech, there is no longer something to do as quickly as you have complete you artwork!! hahah

- Q:can i cast polyurethane resin in a polymer modelling clay?

- in my 30 some yrs as a contractor i have never had anyone request them.u never hear of houses gettting struck so people out grew them..but they work if installed lic. gen. contractor

- Q:Need info to purchase the lock

- you'll need much more than repairing. you should contact microsofts customer service or norton customer service

- Q:I have an adorable track suit that I purchased from Victoria's Secret ages ago (the kind that nobody ever actually wears for track.. ^_~), and it's made from deep wine-red velour. I went to put it on earlier, and realized that while the *outside* was soft, sensual velour, the *inside* was scratchy and not all that soft.It's the same way with clothing that's satin, or silk, or velvet, or that smooth satin-like fabric that I don't know the name of it always feels wonderful on the *outside*, but *not* on the part that's against my skin.Why is this??

- This Site Might Help You. RE: Consumer product safety act of 1972? What was the consumer issue that caused the need for the act? Why the revelent consumer issue became inmportant at the time the act was passed? was there a specific chain of events that led to the legislation who promoted the legislation?

- Q:What 17th century Catholic Priest invented the first working parachute?

- The alarm buttons on the key locker things *i dont know what to call them either* require you to hold the buttoun down for about 3 seconds so you definetley shouldn't worry about hitting it by accident

- Q:what is the proper procedure for sweating copper pipe fittings?

- Devil wears Prada But Zilla's in asbestos? Fashion disaster!

- Q:So far I have the Marchesa Luisa Casati, Anna Piaggi, and Isabella Blow. Anyone else? I love eccentric, strange, avante garde women!

- This probably means the backup battery is low. Get maintenance up there. Even if you have to make an emergency calldo it! They're responsible for maintaining the alarm system, not you. They should regularly change the batteries to prevent things like this from happening.

- Q:Is it used in Thai or Balanese cooking and if so, how please?

- You can use the adapter at the dryer or on the wallone way it's a reducer from your dryer where you hose is a 3 hose. or it's a reducer at the end of 4 hose to fit the 3 wall mount. Either way it will be OK.

- Q:OK I was 12 when I started wetting the bed.I just wasent once or twice it was everyday.I started wearing a diaper.I would fill it up then it would leak out .To make it worse my mom would make my sister go to the store to get daipers .She always bought boy super hero or transformer.Then should would take me to the store just to pull down my pANTS.I got rubber sheets.but it still leaked out.One time i went camping with a friend .i leaked all in the tent.I was still sleeping so my friend took a picture of me with my front wet, and my diaper completely fullCAN YOU TELL ME YOUR STORY OR SOMTHING THAT COULD HELP IM 14 WETTING THE BED HELP AM I WIERD OR A LOOSER

- What you will need is plenty of 4, 3, 2, 11/2 schedule 40 DWV PVC pipe. Plenty of fittings, and a 4 twin clean-out. A couple of quart cans of primer glue, a trencher, a tape measure, hammer a few long stakes, a torpedo level..and a good saw. You will also need a couple rolls of 3/4 type L soft copper, and depending on the size house, 2 to 3 rolls 1/2 type L soft copper. The copper fittings to make a distribution manifold at the water heater. An acetylene B tank torch, some sand cloth, tinning flux and a roll of lead-free solder. You have to know how to read the plans in order to get any water lines that are in the center of the wall it stubs up into, as well as where to rough-in the main trunk drain line, its branches and vent stacks for easy drainage. You have to know how to weld without wasting solder and clogging the pipe. You will have to know what to do after the frame of the house is put up and the second stage entails; stubbing up out and running stack-out. When the house is almost finished, its time for fixtures. AND you have to do it all following your state/county/city plumbing codes for what size pipe can run what and get a permit inspection. You cannot move ahead to the next stage without a green tag. Think you can handle it? It takes some apprentices at least two years of the three required before he can take the license test to get a clear vision of how to not waste materials and still design a system that works without fail for decades and decades. So, to answer your query: Yes, its hard.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Profesisonal Carbon Fiber Tube/Rod/Plate Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords