Pre-galvanized steelbearing plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000Tons m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fire and bearing, can provide 4 hours of refractory time limit and bearing load of 10Kpa.

Application: civilian reconstruction project (hotels, hotels, shopping malls, office building, workshop transformation) and the new project (slab, steel structure project of offshore drilling platform, hull load-bearing deck) etc..

Its characteristics: Fire 4 hours bearing 10Kpa; can be placed in the load-bearing floor on electromechanical equipment group;

Provide the personnel operating platform; instead of traditional steel plate concrete floor, floor, installation fast, no need of maintenance

| Effective width | Wall panel: 950mm 1150mm Roof panel: 960mm |

| Length | According to customer's request |

| Materials | Rock wool, Color steel sheet |

| Structure | Upper and lower layer: Color steel sheet |

| Middle: Rock wool | |

| Thickness | Color steel sheet: 0.3-0.6mm Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm |

| The rock wool density | 110kg/m3 120kg/m3 |

| Conventional color | Ocean blue, whitegrey, etc |

| Character | Fireproof, heat insulation, green and environmental |

| Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

- Q:Are thermocol roof insulation boards or thermocole sandwich concrete bricks durable?

- I typed in thermocol and this is what it gave me. Hope it helps. polystyrene (p?l'ēstī`rēn), widely used plastic plastic, any organic material with the ability to flow into a desired shape when heat and pressure are applied to it and to retain the shape when they are withdrawn. Polystyrene is a colorless, transparent thermoplastic that softens slightly above 100°C; (212°F;) and becomes a viscous liquid at around 185°C; (365°F;). It is resistant to acids, alkalies, oils, and alcohols. It is produced either as a solid or as a foamed plastic marketed under the trade name Styrofoam. Its many uses include electrical and thermal insulation, translucent window panels, storage-battery cases, and toilet articles

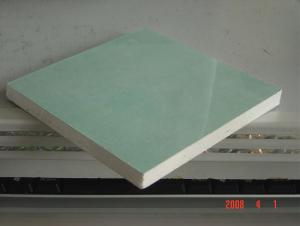

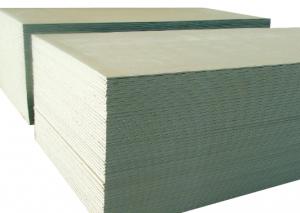

- Q:What is the proportion of gypsum board?

- Gypsum board generally used surface density measurement, for example: 9.5mm thickness gypsum board, the national standard requires its surface density to be less than 9.5Kg / m2, but most of the better quality gypsum board density control in (6.5-7.2) Kg / M2. If compared with the density of water, the proportion of ordinary gypsum board is less than water. But the refractory board due to gypsum core inside the addition of glass fiber, depending on the amount of added, the density may be greater than the density of water.

- Q:Industrial building facades

- There are standard Atlas can be checked, such as 01J925-1 pressure plate, sandwich panel roof and wall construction, 06J925-2 pressure plate. Sandwich panel roof and wall construction (2), 08J925-3 pressure Steel plate, sandwich panel roof and wall structure (3).

- Q:Although the overall wardrobe in recent years in the rise of the country, but its development is very fast, and has long been a modern 80,90 home improvement after their favorite clothes storage products, but can be used to make the overall wardrobe plate quite much, For all kinds of products, as a layman of the consumer how to identify the pros and cons of wardrobe plate it? Well-known overall wardrobe business - the Federal Shangguan Road wardrobe business Xiaobian here for you to carry out the following Weapon, hoping to help more potential consumers of the overall wardrobe to understand this related knowledge. , Is the overall wardrobe is necessary, in the purchase of the whole wardrobe, the plate is a direct impact on the overall quality of the final wardrobe effect, for those who do not understand the board is not a friend , How to determine the quality of the plate it?

- Third, the table to be like: to see the side plate hole material; many businesses in the use of materials are often used when some poor quality material, the other overall wardrobe in the process of continuous exposure to more defects.

- Q:Home decoration what plate is good?

- Skin thickness. See the thickness of the board, the thicker the better the performance, the better the real wood after the paint, the texture is also more clear, bright color saturation is good. How to identify the thickness of the panel? Kanban whether the edge of the sand through the board with or without glue, coated with water to see whether the pan-green, transparent phenomenon. If there is such a problem, it belongs to the panel skin is thin.

- Q:How to buy plate formaldehyde climate chamber?

- Buy formaldehyde climate box to focus on the following aspects: ????? 1, to find professional R & D manufacturers to buy, more than a few comparison, assessment of comprehensive strength! ????? 2, test box test parameters and test environment to meet the relevant standards and parameters! ????? 3, combined with their own products, choose the appropriate test space! ????? 4, formaldehyde climate test chamber should have a sophisticated test mode and improve the structure and security system! ????? 5, the price is better! A variety of configurations should be genuine to ensure the use of quality! ????? Combined with formaldehyde self-test characteristics of the proposed reference Zhengbang Detection Equipment Co., Ltd. Furniture formaldehyde test technology:

- Q:Will the sheet metal processing bending coefficient and plate thickness, bending angle, bending radius is what is the relationship between the urgent!

- The bending factor and the thickness of the material you said bending angle ah bend the radius and bending the bending machine up and down mold, the length of the bending parts are related We are using experience value. After all, conventional standard brick algorithm does not take into account the equipment wear and tear, sheet material thickness of the situation Different thickness determines the different bending factors such as 1mm cold rolling fold 90 degrees and 2mm cold rolling fold 90 degrees Our actual situation is 1mm coefficient is 1.8 2mm coefficient is 3.5 The same angle 90 degrees is a bending factor of 60 degrees is 1/2 of the bending coefficient of 45 degrees is 1/3 of the bending coefficient of less than 30 degrees according to the different thickness of the buckle or buckle a 0.5 Material and plate thickness as different materials, the bending coefficient is different The bending radius is related to the bending machine. The standard single V or double V is even the default value of the other V slots. But there are customers who need to be too small or a large bend radius will be specific to the analysis Too small bend radius, our approach is to plan the groove to bend, so that the bending radius is very small, almost vertical right angle bending Too large bending radius, the upper mold can be used on the corresponding arc on the mold (note that the upper arc of the R is the inside of your bending R, if the outside R according to the outer R minus a plate thickness to determine the model) Or a large R30 50 or more, you can use a split bend, which requires the calculation of the cut-in angle and the last knife angle, as well as the size and angle of each knife There is a part of the length of this I think a lot or machine equipment and related to our machine a long time 1.5mm stainless steel over 1m according to the case will not use 8mm mold bending

- Q:Color steel sandwich panel of the scope of what, what is the benefits of this sandwich board, the purchase of the price of the number of appropriate? Housing construction with this sandwich board can

- Printing color steel are applicable to the sandwich board industry, not to mention monochrome steel, and now has a composite plate steel structure, activities, external walls of metal carved panels, integrated insulation board, light steel villas and so can be used, , Rich colors, is a new type of energy saving and environmental protection composite materials, the price can go to contact Jiangyin Wo Fung metal, as if the price is not the same price, is based on your requirements to account, sandwich board used in the house certainly no problem.

- Q:What is FR4 sheet

- FR-4 is a glass fiber epoxy resin CCL, a circuit board in the substrate, in fact, you should have seen, such as the kind of small game machine to open, inside the green board is FR-4 to do circuit board. FR4FR5 epoxy board by a special electronic cloth impregnated with epoxy phenolic resin and other materials by high temperature and high pressure hot plate made of laminated products. With high mechanical properties and dielectric properties, good insulation properties and heat resistance and moisture resistance, and a good mechanical processing. Application: for electrical and electrical equipment for the insulation structure of parts, also widely used In the PCB test; and can be used in humid environmental conditions and transformer oil.

- Q:I'm renovating a 110year old end terrace. Plaster is all off right back to brick and I'm re plastering myself when the time comes. I took a professional quote and the contractor said that for the external facing walls, because I've stripped it all back, I'd need to use insulated plasterboard to conform to building regs??? Is this true? If so what is the minimum standard?

- Only your local code enforcement officer can answer your question properly. Any other answer is just a guess.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-galvanized steelbearing plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000Tons m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords