Calcium Silicate Board from China

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container m²

- Supply Capability:

- 60Containers/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

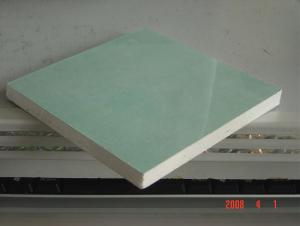

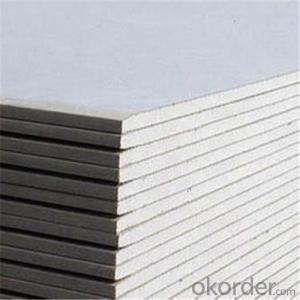

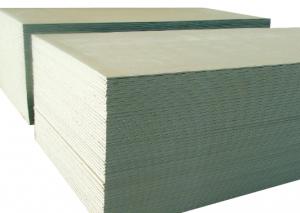

Description of Gypsum Board:

1.We have three kinds of gypsum board, regular gypsum board, fire-proof gypsum board and moisture resistant gypsum board. And our product are mainly used for Ceiling system, Partitio system, Dry lining system and we also provide its allied system such as: Channels, joint compound, joint tape, screws and so on.

2.Gypsum board edge:

Tapered edge (recessed edge) And Square edge (straight)

Raw Materials of Gypsum Board:

Using high purity gypsum powder as main material and mixed with fiber and highquality additive

SIZE: (mm)1200*2400 1220*2440 1200*3600 1220*3600 1200*2500 1220*2500

Thickness: ( mm) 6.4 to 16

Applications of Gypsum Board:

1: Ceiling system,

2: Partition system,

3: Dry lining system

Package of Gypsum Board

1.Naked with bulk in container by hand

2.Load with pallet by forklift

Production Flow:

We have 5 production line for gypsum board, 60 containers can be produced per month.

- Q:What distance do the dry wall screws have to be and what do i fill the joint gaps with before plastering. Is there a british standard ?

- I would nail it with sheetrock nails.......but if you are pounding on someone else's half of the wall I would use sheet rock screws. You can put one in about every 8 across a stud. Try not to break the paper. For the joints instead of paper tape I use fiberglass self sticking tape.........it's usually blue or yellow and mud right over it. If you are going to plaster it well that's the same tape but a little different application of the mud. I just hand texture the mud and do a knock down trowel finish.......it looks nice.......and is fairly simple to do.

- Q:What is the price of the living room ceiling now?

- Living room ceiling can do gypsum can also be integrated, the practice of different prices are not the same, the shape of the complex price is relatively high, but also depends on the local labor costs, material is not expensive labor costs. Wood keel + gypsum board, generally per square meter in accordance with 00 yuan or so, gypsum board requires a good quality, you have to according to II 0 or so. Light steel keel + gypsum board, generally per square meter in accordance with the II 0 - according to 50, if it is shaped, in the bar 0 to II II have between. There is also the use of integrated ceiling to do the living room, as if generally in the 0000-00 or so per square meter. It is recommended that you choose the appropriate ceiling according to the decoration style

- Q:Can you wipe the cement mortar on the gypsum board?

- Can not. Need to add a layer of cement board in the gypsum board, and then you can operate the tile.

- Q:It's a strip light but although I'm putting plugs in, after I drill the holes, as soon as I put the hooks up to hold the light the plugs just keep coming out....any suggestions?

- It's not a good idea to depend on the plasterboard for support. What you should do is locate the a ceiling joist (or truss) and secure the hooks to it with screws. You sure do not want to chance having the light come crashing down.

- Q:Gypsum board ceiling price how much?

- With more thick gypsum board, in general, 9mm with 12mm two, the lowest price is 18,37 each, the brand, then about 10 yuan per element you do not use what material keel, in general, wood Square and light steel two, the lowest price is, anti-corrosion wood side 25 a bundle of four (400 * 25 * 25), light steel 8 dollars a main keel 30mm wide. An average of 10 dollars per square meter of wood, light steel 12 dollars. Accessories, steam nails nails, dry hanging nails, white latex, etc., more than 100 square meters, less than 2 yuan per square meter. Wages, the gap is relatively large, in general, an area of more than 100 square meters, flat top 40, modeling roof (with light pool or bump shape) 60 square meters, if it is a large city may be higher. In summary, the gypsum board ceiling (single, no curve shape) cost is generally between 75-180 dollars, if the workers quote the profits on the float is about 30% Want to answer to help you, hope to adopt

- Q:can i put 8ft by 4ft plasterboards on a ceiling?

- Of course you can.... 1/2 thick is recommended.... Are you going over an existing ceiling? is this new construction..need more information.... Perhaps you ask cuz the room is larger than 8' wide....It would be better to have full lengths wall to wall, but not necessary, just a bit harder to tape. but this is done on most ceilings. If you can get longer sheets, it would make for a better job, but perhaps, it is not possible to fit the longer sheets into the space.... To avoid the expense of a drywall lift, make t-heads about an inch longer than the ceiling ht, and use them to hold up the sheet while you screw....have a helper...to make the job run smoother

- Q:How to identify waterproof gypsum board and general gypsum board?

- 1, the difference between the two is that: ordinary gypsum board core and the surface layer and the surface layer of materials do not do waterproof; and waterproof gypsum board core and the surface layer and surface material to do waterproofing. 2, ordinary gypsum surface into a gray paper, double-sided color the same, waterproof gypsum board, also known as cement pressure board with white and dark gray, the surface side is smooth, one side is rough; general interior latex paint is not waterproof, Exterior wall paint is waterproof.

- Q:GRC is not commonly known as gypsum board

- Grc components are cement-based alkali-resistant glass fiber reinforced concrete components, and gypsum board is based on building gypsum as the main raw material made of a material, the material is not the same ah. If grc component works, Guangyou grc can be opened next to the factory goods, so that can be installed directly.

- Q:I need to put up a platerboard in bathroom cover cover up old loft hatch? do i need to dampproof this somehow as in bathroom where there is a lot of steam? or can i just put this up and skim it over?

- Get other ppl's help.

- Q:Gypsum board wall can be installed after the door suction it?

- Due to restrictions on the gypsum board material recommended Do not install the door in the wall can be installed in the wall from the wall ten cm on the floor

1. Manufacturer Overview |

|

|---|---|

| Location | Shangdong, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 30.00% Mid East 30.00% Africa 20.00% Southeast Asia 10.00% Domestic Market 5.00% South America 5.00% North America |

| Company Certifications | third-party verification service provider |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above3000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average; Low |

Send your message to us

Calcium Silicate Board from China

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container m²

- Supply Capability:

- 60Containers/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords