Rock wool sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sandwich Panel definition

Sandwich panels for building applications are large prefabricated building products.

Sandwich panels generally consist of two outer metal sheets (steel, aluminium, other) with a stabilizing core of insulation sandwiched between them. The metal sheets are bonded to the insulation core with specialised adhesives. The outer surface of the sheets can be flat, slightly corrugated or with a significant profile (eg. for roofs or external façade design). A huge assortment of shapes, coatings and colours is available. Because sandwich panel installation requires only a limited number of mechanical fasteners (eg. screws), the resulting constructions avoid significant thermal bridging. To achieve distinctive architectural features, panels with hidden joints are available.

Since 2009 a new European standard EN 14509 has defined the regulation and quality of sandwich panels with insulating core materials.

At ROCKWOOL our sandwich panel specialists are trained to support sandwich panel producers and other component suppliers to achieve maximum panel performance. For many years ROCKWOOL has developed and supplied robust insulation core materials for sandwich panel solutions worldwide

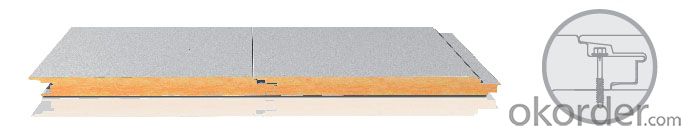

Rock wool composite wall panel system (vertical) -- MQ1-T-W

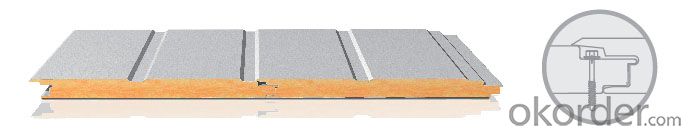

Rock wool composite wall panel system (horizontal) -- MQ2-T-W

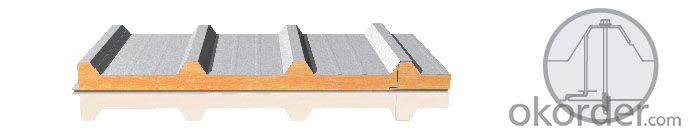

Rock wool composite wall panel system (horizontal) -- MQ3-T-W

panel thickness T=50mm 80mm 100mm 120mm 150mm

panel width W=600mm-1000mm

Rock wool composite roof system -- MW1-T-W

Xinxin's rock wool sandwich panle with two layers of color steel bonded and a high density rock wool fire proofing, insulation core material formed in the middle as a whole, can be widely used in a fire, sound and heat insulation requirements of public, business and indestrial constrction.

panel thickness T=50mm 80mm 100mm 120mm 150mm

panel width W=1000mm

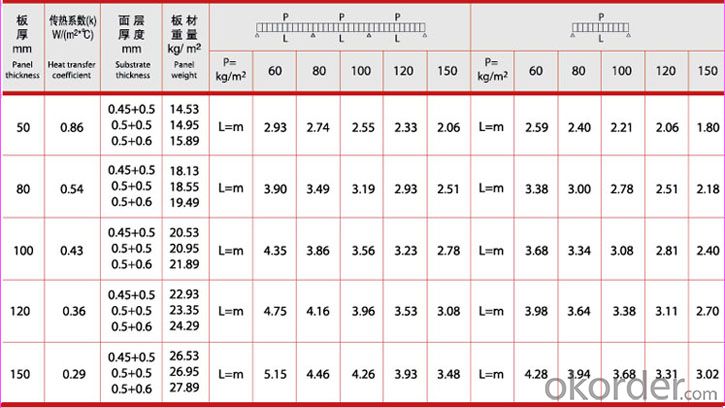

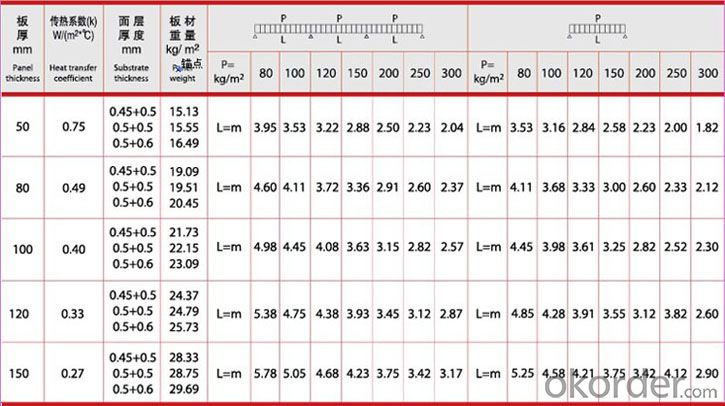

Metal surface rock wool sandwich panel design specifications

1.Wall plate allows vertical load, span, heat transfer coefficient (Allowable Distortions f≤L/240)

Core density = 120 kg/m3

2.Roof plate allows vertical load, span, heat transfer coefficient (Allowable Distortions f≤L/200)

Core density = 120 kg/m3

- Q:Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of tile it?

- First of all, rock wool sandwich panels can not do external wall insulation, but can not paste tiles. Lz on the external wall insulation system is not very understanding. In addition, A-class insulation of the external wall insulation material is now the most used is rock wool, and rock wool external wall insulation has a clear reply, can not be tiled. Rock wool weight is very heavy, if the high-level tile on the words, it is impossible.

- Q:Is the polyurethane sandwich panel and foam board flame retardant?

- On the market, the polyurethane foam flame retardant grade B1, B2, B3 three grades. Because of the cost, sandwich board with the majority of polyurethane material is B3 level, a small amount of B2 level, there are a small amount of special requirements B1 level. B1 level for the 'flame'; B2 level for the 'combustible'; B3 level for the 'flammable'. B1 grade oxygen index requirements of more than 30%; B2 level requirements of more than 26%, 26% of the following collectively referred to as B3 level. You said the flame retardant, it should be self-extinguishing from the fire. B2, B1 from the heat certainly no problem. A little better B3 (oxygen index of about 25%) can also be self-extinguishing, but more than B2 self-extinguishing time more than a few seconds. General oxygen index of less than 24%, it is difficult to self-extinguishing from the fire, will always burn, the greater the greater the burning. The The Oxygen Index: The concentration of oxygen required to stabilize the combustion in the oxygen and nitrogen gas mixture under the specified shape of the foam, the specified source of fire and the size of the flame. - For example, the better the flame retardant properties of the foam, the higher the concentration of oxygen needed to ignite the foam, the higher the oxygen index of the bubble

- Q:What is the ESP sandwich panel

- EPS is polystyrene, which is what we call foam board Sandwich refers to the foam as the core material, the external double-sided composite material of other plates. Other plate is generally the majority of color steel plate.

- Q:Rock wool color steel sandwich panels how to choose

- Shandong Yonggu Building Materials Technology Co., Ltd., Shandong Province is one of the largest manufacturers of insulation materials, the company was founded in 1999, is the production of new energy-saving insulation materials professional manufacturers, is one of the largest phenolic sheet production enterprises, and participated in the The preparation of national standards for the product. Yong company in good faith, innovation, management, technology in all aspects of comprehensive advantages, laid in the new insulation materials on the market position. Yong company introduced a number of patented phenolic products and continuous phenolic composite sheet production line, is committed to the development and improvement of low-temperature phenolic foam resin, hard phenolic foam board, phenolic refractory materials, phenolic wall insulation board, phenolic color steel sandwich Plate and other phenolic products. Now the scale of the production of the core products are phenolic wall insulation board, aluminum foil surface (color plate) phenolic duct plate, phenolic Caigang sandwich panels three series of new technology products. The company has introduced the automatic production line, the production of phenolic foam sheet density uniformity, smooth surface, smooth, to overcome the traditional hand-die large foam behind the process of poor strength, low efficiency, for your project to provide a strong Guarantee. The adoption of international advanced quality management, enterprises through a comprehensive ISO9001 quality system certification, and apply for access to five national patents. The company's superior products Caigang sandwich panels, color steel tile is the China Steel Structure Association designated supporting manufacturers, and won the "Shandong famous brand" "user trust units" and other honorary titles.

- Q:We are the construction unit to the scene into the decoration with the sandwich panels and fire retardant coating supervision requirements were re-test and then also use a good brush-resistant paint sandwich panels to do re-examination Will this want to detect what the purpose of what is the detection of the project. Good people to help answer Thank you

- The purpose of the test is whether the material meets the design requirements The item is refractory grade

- Q:Color steel sandwich panel 75 (0.5 / 0.3) × 1200/1000 said what

- Generally rare 1.2 m and 1.0 m of the board .75 that is certainly the thickness of the sandwich, mm, 0.5 and 0.3 that is certainly the thickness of the metal is also mm. General raw materials are 1 m and 1.2 m, do it , Is 960mm, 950mm, 1150mm.

- Q:What is the fire resistance time of the steel wool

- Light rock wool sandwich panels do not know, rock wool home glass magnesium can then reach more than 2 hours.

- Q:I don't want to gain weight, so is this a healthy one: pita bread, organic peanut butter, and organic grape jelly.

- Yes it is fine as long as the organic peanut butter is low fat and the organic grape jelly is low sugar. Check the ingredients panels.*

- Q:What is the difference between the ecological board and the sandwich board? Which is used to decorate better, what is the price? What are the top ten brands of the two boards?

- The ecological board is made of natural mineral stone powder and natural fiber as the basic raw material, through the inorganic gel technology modification process, through the mold, natural curing molding for the environmental protection and energy saving new materials, which does not contain formaldehyde, toluene inorganic natural environmental performance, Combined with the surface of the natural texture and sustained and efficient negative oxygen ion release, to achieve its natural properties of green building materials. Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor.

- Q:Everybody is the polyurethane sandwich board to which manufacturers to buy?

- I came to tell you that I was buying polyurethane sandwich panels to go to Zhejiang Bo Ya building materials, where their products are not only durable, good quality, but also beautiful, there are a variety of styles, all kinds of places can be used on the

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rock wool sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords