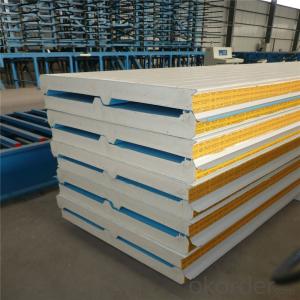

Low cost Pu Polyurethane Sandwich Panels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low cost Pu Polyurethane Sandwich Panels

PU Sandwich Panel advantages

1. Effective insulation

2. Excellent corrosion and weather resistance

3. Moisture proof and waterproof

4. Anti freeze-thaw and sound absorption

5. Energy efficiency and cost saving

6. Fireproof and high temperature resistance

7. Anti-deformation and hardly to be cracked

8. Beautiful appearance and easy installation

Building function:We will recommend the proper panel type and the best technical solution for you according to it

Fire resistance requirement standard of the project

Panel specification: Length*Wide*Thickness, peak height

Types of core material for your choice: PUR and PIR, EPS, rock wool, glass wool

Density: by your requirment

Surface material:prepainted steel plate

Panel color:For special colors, sample panels are negotiable

Coating type: Polyester type(PE), silicone modified polyester type(SMP), highly weather-resistant type(HDP) and fluorocarbon type(PVDF)

Surface profile:Ripple , plat , relief and square wave.

Steel sheet thickness:0.3-0.8mm

Steel sheet treatment:hot dip galvanized, Al-Zn coated

Manner of packing

Lead time

Applications of PU sandwich panel

PU Sandwich panels cover all applications in steel building construction and prefabricated houses: external walls, roofs, partitions, ceiling panels, acoustic sandwich panels forworkshops,warehouse,cold room, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

Our project cases with PU sandwich panels

Workshops

Houses in Australia

- Q:Do the wardrobe with a wooden sandwich board or solid wood particle board is good

- Solid wood particle board moisture-proof effect than the wood sandwich board moisture effect is much better Solid wood particle board and wood sandwich board difference 1, solid wood particle board, is made of wood or other lignocellulosic material, the application of adhesive after the heat and pressure under the action of synthetic wood-based panel. Solid wood particle board as a new, high-grade environmentally friendly substrate. Solid wood particle plate inside the cross-scattered structure of the granular. So the nail force is good, you can nail round nails, screws. These machinability is significantly better than MDF. 2, solid wood particle density is higher, the board of wood fiber particles larger, more to retain the nature of natural wood, in the use of solid wood particles on the board content is generally less than 5%, better environmental protection. Solid wood grain plate warp deformation small, stable size, good, high strength, good stiffness, hanging heavy clothing is not easy to bend. At present in the European furniture market, the use of wood-based panel is also solid wood particle board. 3, wood sandwich panels inside and outside the two sides for the glass plate, sandwich layer waterproof plywood, the German vacuum technology from high pressure compound. Sandwich panel surface smooth, dirt can be easily removed, the entire panel colorful, with excellent light retention. 4, fiberglass plate surface has a layer of excellent performance gel coat, the atmosphere, water and the general concentration of acid, alkali, salt and other media has a good chemical stability; surface finish, excellent light retention, no discoloration, corrosion resistance , Anti-sun, anti-aging. The main application areas: dry cargo compartment, large span structure roof, wall, purification plant, high profile portfolio housing, container rooms and so on.

- Q:Whether the rock wool sandwich panel is environmentally friendly

- How to say this, the board itself is environmentally friendly, the production process is not environmentally friendly ~

- Q:What is the acceptance criteria for rock wool sandwich panels?

- The thickness of the insulation layer and the thickness of the thickness of the thick galvanized layer and so on

- Q:Fire rock wool color steel sandwich board 75 thick one square meter how much money?

- The price accounting for fire-resistant rock wool sandwich panels requires a number of factors, including the quality and brand of color steel sandwich panels, and whether rock wool needs hydrophobic rock wool and other factors. For specific price accounting please contact the business.

- Q:Solid wood sandwich board how much money a piece

- Manufacturers to take the words of 185 yuan, other places to more than 200

- Q:Is the sandwich panel a mezzanine? What is the effect of painting? How long can I use life on the cabinet? Best example! My house in the decoration What is the cost of a sheet plus paint? Will the board be put on the floor after painting and painting?

- Sandwich panels do not refer to blockboards, because the sandwich panels are many kinds, including three PCT board, five PCT board, nine PCT board ... ... can only say that the blockboard is a kind of sandwich panels. Not directly in the blockboard on the paint, usually on the outside to paste decorative panels, and then clear oil process, if you want to paint directly on the plate, please use medium density board, used for making furniture, oil mixing process! Maintenance is good, life is not a problem! But can buy as much as possible to buy, do not live production. After all, the scene can not reach the factory clean paint, and did not sell the beautiful. ???? The general plate is not very expensive, but do not underestimate the paint! Will the board be put on the floor after painting and painting? The answer is yes, the plate had to nail a layer of gypsum board, and then putty putty paint, so that will not be delaminated.

- Q:What kind of support is needed

- Fix the screws on the C steel

- Q:Color steel sandwich panel of the scope of what, what is the benefits of this sandwich board, the purchase of the price of the number of appropriate? Housing construction with this sandwich board can

- Printing color steel are applicable to the sandwich board industry, not to mention monochrome steel, and now has a composite plate steel structure, activities, external walls of metal carved panels, integrated insulation board, light steel villas and so can be used, , Rich colors, is a new type of energy saving and environmental protection composite materials, the price can go to contact Jiangyin Wo Fung metal, as if the price is not the same price, is based on your requirements to account, sandwich board used in the house certainly no problem.

- Q:And where are you? Will there be any differences in prices? I am Yuyao, Zhejiang

- 0.5 thick foam board 55 is certainly not buy, even if the real 55 is also cut corners, the basic price of 65 or so, excluding tax, if you want to pack the plate, then more expensive. There is the roof, then the general use of corrugated board, the price is higher. Between 72-75, look at the request. We are here in Suzhou. Can be contacted

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low cost Pu Polyurethane Sandwich Panels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords