Gypsum Board for Drywall

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

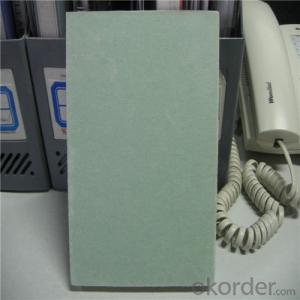

CMAX Gypsum Board Drywall Introduction.

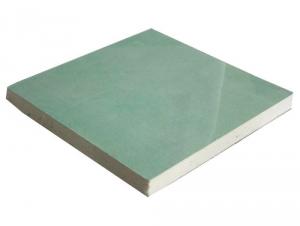

Your drywall can be virtually any shape, anywhere. Choose from a wide range of heavy-duty system options that provide code-compliant performance in both fire rated and non-fire rated applications with labor-saving advantages.

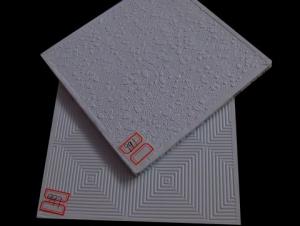

1.Gypsum Board Drywall Specification.

Convenient Construction | The plaster board can be constructed easily by nailing ,cuting and planing,and thus it becomes the first choice among home decoration materials. |

Raw material | The gypsum board is characterized for lightness and high intensity,dryness operation, green environmental protect, convenient construction and good processing quality. |

Size | 595x595 |

605x605 | |

1200x2400 | |

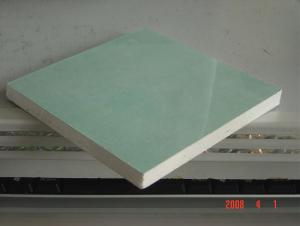

1220x2440 | |

Thickness | 7,7.5,8,9,9.5,10,12,12.5,13,15,15.9 |

Surface treatment | Paper/PVC laminated/foil back |

Production capacity | 10,000m2/day |

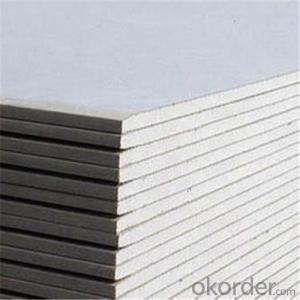

2.Gypsum Board of ceiling & wall partition system.

CMAX System is a modern, non-load bearing and quickly assembled on site. The system consists of Gypsum Board screw fixed to lightweight galvanized metal sections and joint finished with drywall system is suitable for all internal applications for commercial and residential.

Exquisite, Modern and Adjustable

CMAX drywall system provides smooth, seamless and crack-free wall surface. Thanks to the distinctive property of CMAX gypsum Board, it allows easy further decoration by either painting or wallpaper work. Moreover, a renovation can be done easily without any disturbance of office building structure.

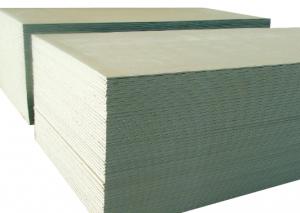

Durable and Standard Quality

Materials and accessories of CMAX wall system are manufactured by state of the art technology in accordance with international standards, such as, British Standard and The American Society for Testing and Materials. Customers therefore can be assured of safety, standard quality and high durabiltity of PRANCE Wall systems.

Lightweight, Easy to Install and Economic

CMAX wall weight much less than masonry partitions of comparable thickness, thus providing real savings in structural design. This enables quick and easy installation, and produces time and cost savings.

Specially Designed and Patented Materials of Gyproc

High quality galvanized CMAX frame metal sections of drywall system are manufactured by state of the art technology called drywall STEEL, to reinforce the cross section of metal sections. C-Stud is also specially designed to be easy when connected, which suits applications requiring extra strength or for length extension of C-Stud. Ready-punched holes from factory provide excellent incorporation of services.

Applicable to Various Usages as Required

CMAX wall system can be designed to suit various types of office application.

Office buildings requiring extra fine resistance, standard drywall system can provide a half-hour fire resistance. Other drywall Systems are also available to provide resistance up to 2 hours.

Other special properties such as heat insulation wall, high moisture resistant wall, acoustic wall, can also be provided by drywall system.

- Q:On further inspection it is more like cardboard than plasterboard. Horrible!

- re-tile, maybe? pull loose tiles off, see as to what extent the sheetrock or backer board is damaged. Then replace that part and install tile back over. No! silicone is not your answer.

- Q:The mirror is about 75cm wide and 50cm high. Can it be hung on a plasterboard wall? What type of screws or nails do I need?

- Yup, just like the answer before mine say's you need the proper wall-anchors for it and you will all set.

- Q:Can you tape and plaster joints only on plasterboard? IE not skim whole room?

- Yes, you can. You will find that the plaster board will soak up more paint that regular drywall. This is because there is a special paper on the plaster board that allows the plaster to stick to it. Plaster board is sometimes called blue board, and you'll know why when you look at the two side by side. When you get ready to paint, you might want to consider two coats of primer.

- Q:Gypsum board size

- The size of the general large gypsum board is 1.2 meters wide and 2.4 meters long.

- Q:How do you paint a stone on a gypsum board?

- Gypsum board can be sprayed with a really small stone spray gun or a real stone sprayer spray. The general construction are coated with a layer of cement slurry, spray the real stone paint is rare.

- Q:As far as i know my walls and roof of my room are made from plasterboard.These wont be strong enough to support a bag will they?tah

- Plasterboard definitely won't hold the weight of a punch bag! Not if it's a decent expensive punch bag anyway! x

- Q:Silicon calcium board and gypsum board price?

- First of all, the price is a regional difference, the best in the local building materials market inspection. Second, the use of two kinds of plates are different, calcium calcium board is not afraid of water, can be used for the bathroom and other areas of wet areas, but because of its construction is not convenient, it is generally more common with water-resistant gypsum board. The gypsum board is more commonly used in the top and wall decoration materials, because of its easy construction characteristics, it was recognized and widely used. In terms of cost, silicon calcium board is generally 2 to 3 times the gypsum board, which is why the use of gypsum board more reasons.

- Q:So, I accidently flooded my bath. The skirting boards around the sink and wood that boxes around the sink have become damp which has now dried out but the wood has cracked and I suppose that it's become warped. Now, I'm not sure how to deal with this as this wood is attached to the plasterboard wall. By removing this wood and replacing it I fear that I might damage the plasterboard wall.Any advice on how to tackle this? I kind of want some advice before I look into calling someone out

- With a sharp razor knife, score along the top edge of the base trim. Take a wide putty knife and force it between the plaster and the base trim. Try to gently pry the trim away from the wall using the putty knife. If the trim won't pry away, take a flat profile pry bar and wedge the bar between the putty knife and the trim. Use the putty knife as the pivot point for the flat bar so that the plaster isn't excessively damaged. If the plaster does crack, you can use a wider profile base trim to help cover the damaged areas.

- Q:Gypsum board ceiling generally need high?

- Reasonable shelving height at least to control between two meters six to seven, but also take into account the floor and floor tiles height, and so on the height of the whole room without special circumstances should be controlled in the same frame, the ground can have a certain Drop.

- Q:Bedroom ceiling with a good board or gypsum board good? What is the advantage? What is the downside? what is the price?

- Gypsum is good. No need to use the board, the price difference between the two great, if the top things do not put things gypsum absolutely no problem.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gypsum Board for Drywall

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords