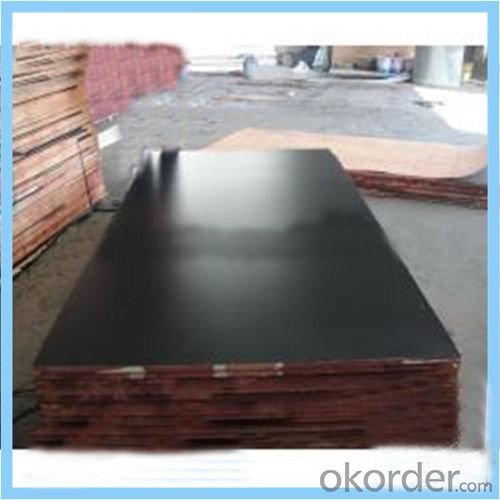

9mm & 12mm Black Film Faced Plywood for Nepal Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 53 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Brand Name: CHANTA

· Model Number: Film Faced Plywood L003

· Usage: Outdoor, Outdoor

· Grade: First-Class, First-Class

· Main Material: Poplar, Poplar

· Formaldehyde Emission Standards: E1

· Plywood Type: 13-Ply Boards, Film Faced Plywood

· Thickness: 9~20mm

· Moisture: about 12%

· Glue: WBP

· Certificate: CE, FSC, CARB, ISO9001:2000

· Film: Black/Brown

· Size: 1220x2440mm

Packaging & Delivery:

Packaging Details: | Inter packing: 0.20mm plastic bag;Outer packing: pallets are covered with plywood or carton and then steel strips for strength |

Delivery Detail: | within 20 days upon the receipt of L/C or T/T |

Product Description:

FILM FACED PLYWOOD

size | 1220*2440mm/1250*2500mm |

thickness | 6mm,9mm,12mm,13.5mm,15mm,18mm,21mm |

core | poplar,birch,hardwood,combi or as your request |

film | black /brown ,Anti Sip film |

density | 500-700kgs/cbm |

moisture | less than 12% |

Thickenss tolerance | +/-0.5mm |

Modulus of rupture | ≥30Mpa |

Modulus of Elasticity | ≥ 6000MPa |

packing | bulk or standard pallet packing |

delivery time | within 15 days after received the deposit |

payment | 30% deposit TT, L/C at sight. |

Nepal Market Plywood 9mm 12mm Black Film Faced Plywood

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Our Mission: provide customers with high quality and service!

- Q:Wenzhou Caigang tile and sandwich panels, steel processing costs is how much

- Color steel tile processing 12 yuan package contractor price 70-90 Stainless steel staircase handrail 60-90 steel 80-180 Unit: per square

- Q:Color steel sandwich panels can be used for many years

- If it is GB double-sided 0.45MM Baosteel foam 16KG / M, then 25 years certainly no problem

- Q:What is the acceptance criteria for rock wool sandwich panels?

- The thickness of the insulation layer and the thickness of the thickness of the thick galvanized layer and so on

- Q:Flammable and toxic "" "", how long life?

- There are two types of polyurethane foam and polystyrene foam!

- Q:Rock wool sandwich panel price rock wool sandwich board how much money a square meter

- This depends on the weight of rock wool, as well as color steel kind. If you need, we plant production. This answer is provided by Hebei Chengxin chemical building materials, if satisfied please adopt.

- Q:Not the old bubble sandwich board prices

- Sandwich board 40 yuan per meter type of 5.6 meters 25 sandwich panel 5600 yuan C steel 14 1100 yuan accessories 400 yuan enough sandwich board is 0.25MM / 0.2MM 7.5CM

- Q:Sandwich board machine how much money

- I am the production of color plate machine, and hope to cooperate with you, OKorder Zhongji machinery Yang Yun

- Q:What is the difference between a steel structure installation sandwich panel and a field composite board approach?

- Color steel, also known as: color pressure tile, is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate, it applies to industrial and civil construction, warehouses, special buildings, large span steel housing Roof, wall and interior and exterior decoration, with light, high strength, rich color, convenient construction, earthquake, fire, rain, long life, free.

- Q:Want to buy sandwich panels, where there are good manufacturers?

- I have to tell you, Zhejiang Bo Ya building materials is a relatively well-known domestic one, where their sales quite big, with two or three decades of production experience, technology, equipment are more advanced, so buy sandwich board to them where Yes, good quality is also cheap

- Q:How about the use of colored steel sandwich panels on the balcony

- Can you, inexpensive. Just when the rain is relatively large noise, lighting effect is not ideal If the conditions permit, then recommend the use of glass, 5 +5 plus plastic on the line. The price difference of about 30%. Life is longer than the color steel, low noise, good lighting.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

9mm & 12mm Black Film Faced Plywood for Nepal Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 53 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords