12Mm Supalux

12Mm Supalux Related Searches

12Mm SupaluxHot Searches

12Mm Mdf Price 6Mm Mdf Board Price 12Mm Mdf Price Buy Mdf Board Online India Waterproof Mdf Suppliers 12Mm Mdf Price12Mm Supalux Supplier & Manufacturer from China

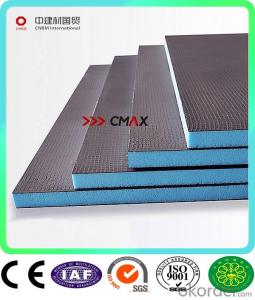

Okorder.com is a professional 12Mm Supalux supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 12Mm Supalux firm in China.Hot Products

FAQ

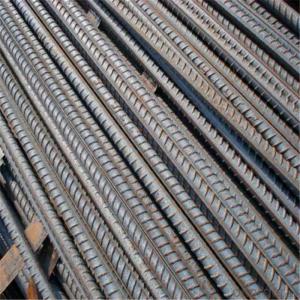

- Steel rebars significantly enhance the overall structural stability of a building. By reinforcing concrete, rebars increase its tensile strength and prevent cracking and failure under heavy loads or external forces. This reinforcement ensures that the building can withstand various stresses, such as earthquakes, wind, and vibrations, improving its durability and safety.

- The constructability and scheduling of concrete projects are greatly influenced by the presence of steel rebars. These reinforcing bars are essential for providing strength and stability to concrete structures, ensuring their durability and resilience. To begin with, the inclusion of steel rebars within the concrete significantly improves the overall structural integrity of the project, enhancing its constructability. By reinforcing and supporting the concrete, the rebars enable the construction of taller and more complex structures. They help distribute the load and withstand tension and compression forces, making the project more reliable. Furthermore, the presence of steel rebars facilitates the scheduling of concrete projects. When properly planned and incorporated, the rebars can expedite construction timelines. By integrating the rebars into the concrete formwork, construction teams can efficiently pour and shape the concrete, reducing the curing time required to achieve the desired strength. This directly affects project scheduling, enabling faster construction progress and potential cost savings. In addition, the utilization of steel rebars in concrete projects allows for flexibility in design and construction. The ability to customize the placement, size, and spacing of rebars ensures that the concrete structure meets specific design requirements and intended functionality. This flexibility becomes particularly crucial in projects that involve intricate architectural features or require specific load-bearing capacities. However, it is important to acknowledge that the proper installation and coordination of steel rebars can present challenges in terms of scheduling. To avoid delays, rebar installation must be carefully coordinated with other construction activities. Moreover, quality control measures are essential to ensure the accurate placement and alignment of rebars, as any errors or deficiencies can significantly impact the overall quality and safety of the project. In conclusion, steel rebars have a significant impact on the constructability and scheduling of concrete projects. They enhance the strength and stability of concrete structures, allowing for the construction of more intricate and robust designs. Additionally, the proper incorporation of rebars can expedite construction timelines and provide flexibility in project scheduling. However, careful planning, coordination, and quality control are necessary to ensure the successful integration of rebars in concrete projects.

- Yes, steel rebars can be used in highway barrier construction. Steel rebars are commonly used as reinforcement in concrete structures, including highway barriers. They provide strength and durability to the barriers, making them capable of withstanding the impact of vehicles and preventing them from crossing into opposing lanes or off the road. Steel rebars are known for their high tensile strength and excellent resistance to corrosion, which are crucial properties for highway barriers that are constantly exposed to harsh weather conditions and heavy traffic loads. Additionally, steel rebars are readily available and cost-effective, making them a preferred choice for highway barrier construction.

- The recommended minimum cover for steel rebars in concrete is typically 1.5 inches for interior applications and 2 inches for exterior applications. However, it is important to consult the local building codes and engineering specifications for specific project requirements.

- Steel rebars can help to control and limit crack width in reinforced concrete structures. The presence of rebars provides reinforcement and increases the tensile strength of the concrete. This enhanced strength helps to distribute and redistribute the stresses caused by loads, reducing the likelihood and width of cracks forming in the concrete. Additionally, the rebars act as a barrier, preventing cracks from propagating and limiting their width.

- Yes, there are potential health and safety concerns associated with steel rebars. Some of the common concerns include the risk of physical injury due to improper handling, lifting, or installation of the rebars. Additionally, steel rebars can cause musculoskeletal disorders if workers are exposed to repetitive tasks or awkward postures during their installation. Moreover, steel rebars may contain hazardous materials such as lead or other toxic substances, which can pose health risks if workers are exposed to them through inhalation or direct contact. Therefore, it is important to follow proper safety protocols and use appropriate personal protective equipment when working with steel rebars to minimize these potential health and safety concerns.

- Steel rebars are indeed suitable for use in road and bridge construction. They are widely employed as reinforcement in concrete structures, such as roads and bridges, to bolster their strength and endurance. These rebars are embedded within the concrete, serving to enhance its tensile strength and prevent any cracking or structural failure. The choice of steel rebars for such constructions is driven by their remarkable attributes, including high strength, ductility, and resistance to corrosion. By evenly distributing loads and stresses, they impart greater resilience to the structures, enabling them to withstand heavy traffic and various environmental conditions. Moreover, steel rebars can be easily fabricated and tailored to meet the precise design requirements of road and bridge construction projects.

- Yes, there are some disadvantages to using steel rebars. Firstly, steel rebars can corrode over time, especially in environments with high moisture or exposure to chemicals, which can reduce their strength and durability. Additionally, steel rebars are susceptible to thermal expansion and contraction, leading to cracking in concrete structures. Moreover, steel rebars are heavy and can be challenging to handle and transport, making construction processes more labor-intensive.